Emergency brake release system, control method and hoisting system

A release system and emergency braking technology, applied in the safety of fluid pressure actuation systems, fluid pressure actuation devices, servo motors, etc., can solve problems such as failure to quickly repair faults, slow multiple opening and closing of brakes, uncontrollable and other problems , to achieve the effect of safe, fast and controllable release of heavy objects, reducing the probability of accidents, and continuous and stable opening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

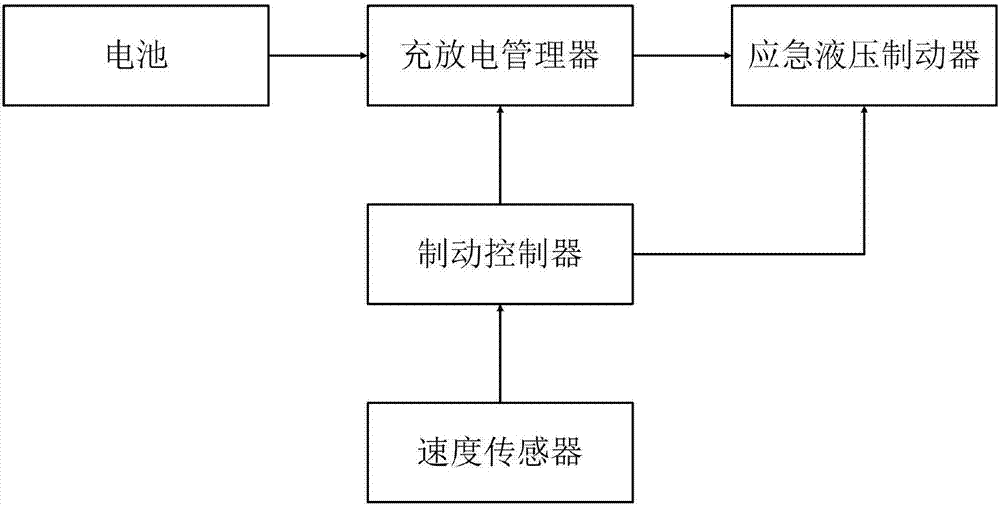

[0035] like figure 1 Shown is a functional block diagram of the emergency brake release system of the present invention: the emergency brake release system provided by the present invention includes a battery, a brake controller, an emergency hydraulic brake, a charging and discharging manager and a speed sensor; the battery is connected The emergency hydraulic brake is used to provide power for the emergency hydraulic brake when the system is powered off; the brake controller is connected to the emergency hydraulic brake to send a control signal to control the operation of the emergency hydraulic brake, so as to realize the release of the lifting mechanism when the power is off. Heavy objects; the charging and discharging manager is connected between the battery and the emergency hydraulic brake, and is used to realize the management of the charging and discharging process of the battery; the speed sensor is used for sampling Increase the speed of the motor, and upload the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com