Drainage pipe and dehumidifier

A drainage pipe and dehumidifier technology, applied in the field of structures and dehumidifiers, can solve the problems of high air outlet temperature of the condenser, affecting user safety and equipment service life, etc., to reduce the air outlet temperature, facilitate batch products and applications, and reduce The effect of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

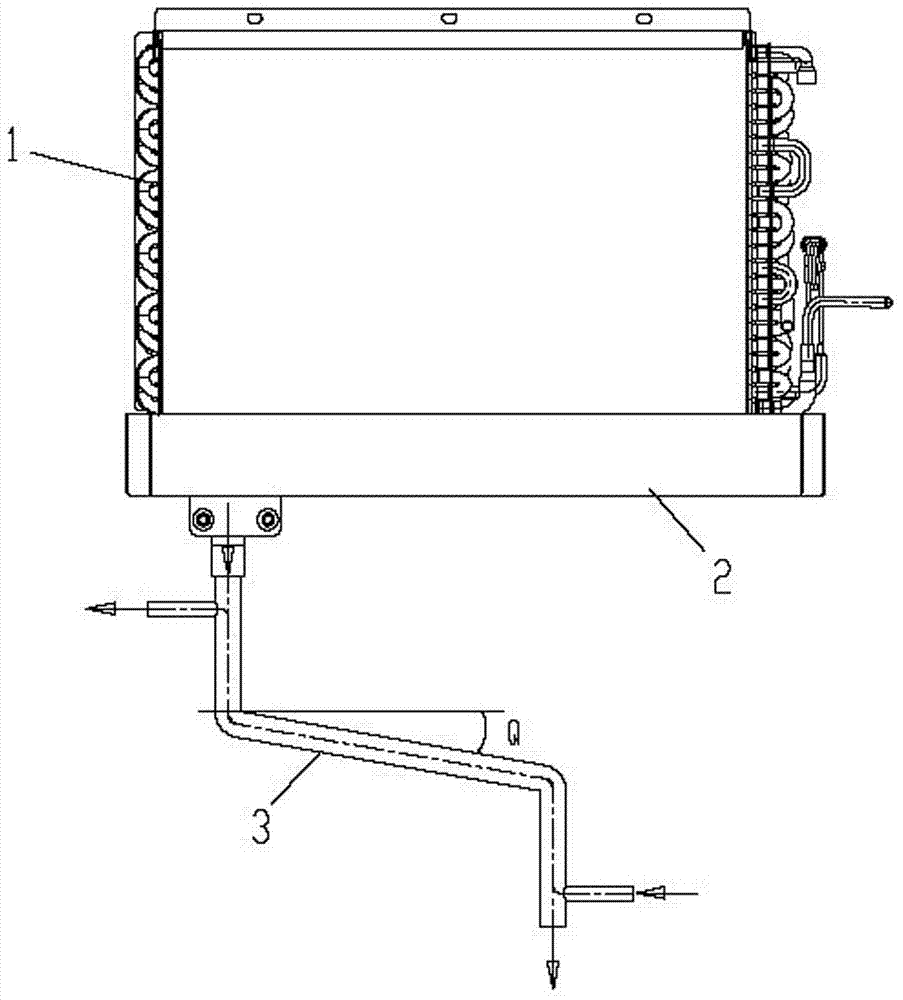

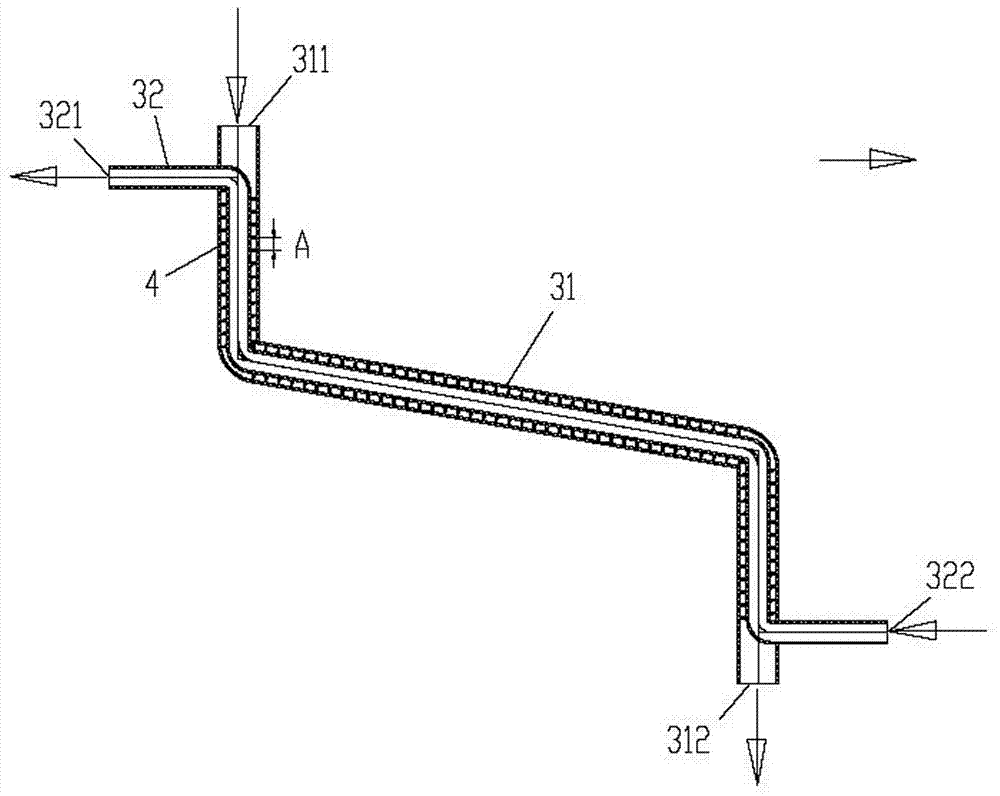

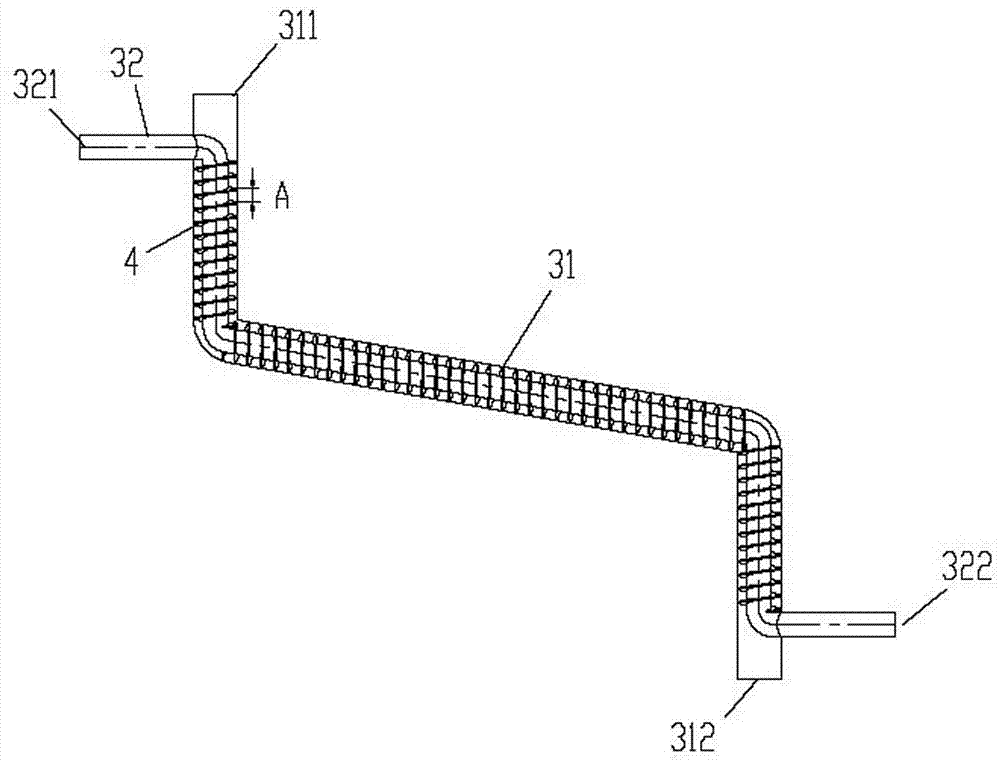

[0026] Embodiment 1, the inlet 311 of the outer layer pipe 31 of the drain pipe is connected to the water receiving tray 2 of the evaporation heat exchanger 1, one port of the inner layer pipe 32 is connected to the exhaust pipe of the compressor, and the other end of the inner layer pipe 32 One port is connected with the intake pipe of the condensing heat exchanger. Specifically, there are two structures: figure 1 As shown, the lower port 322 of the inner pipe 32 can be connected to the discharge pipe of the compressor, and the upper port 321 of the inner pipe 32 can be connected to the intake pipe of the condensing heat exchanger. Then the flow direction of the liquid in the inner layer pipe 32 and the outer layer pipe 31 is opposite. Another structure is: the upper port 321 of the inner layer pipe 32 can be connected with the exhaust pipe of the compressor, and then the lower port 322 of the inner layer pipe 32 can be connected with the intake pipe of the condensing heat e...

Embodiment 2

[0027] Embodiment 2, the inlet 321 of the inner layer pipe 32 of the drain pipe is connected with the water receiving tray 2 of the evaporation heat exchanger 1, one port of the outer layer pipe 31 is connected with the exhaust pipe of the compressor, and the other end of the inner layer pipe 32 One port is connected with the intake pipe of the condensing heat exchanger. Specifically, there are two structures: the lower port 312 of the outer pipe 31 can be connected to the discharge pipe of the compressor, and the upper port 311 of the outer pipe 31 can be connected to the inlet pipe of the condensing heat exchanger. That is, the flow direction of the liquid in the inner pipe 32 and the outer pipe 31 is opposite. Another structure is: the upper port 311 of the outer layer pipe 31 can be connected with the discharge pipe of the compressor, and the lower port 312 of the outer layer pipe 31 can be connected with the inlet pipe of the condensing heat exchanger. That is, the liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com