Equipment standard configuration method in automobile logistics storage

A configuration method and logistics technology, which is applied in logistics, instruments, data processing applications, etc., can solve the problems of randomness in equipment cross-mixing, risks, and waste of idle equipment, so as to improve the utilization rate of equipment resources, improve the degree of standardization, The effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment and working principle of the present invention will be described in further detail below in conjunction with the accompanying drawings.

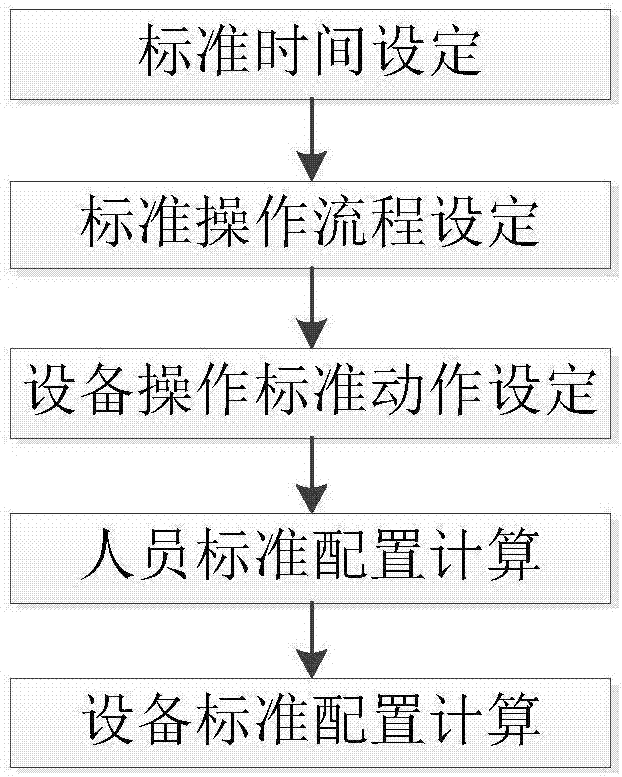

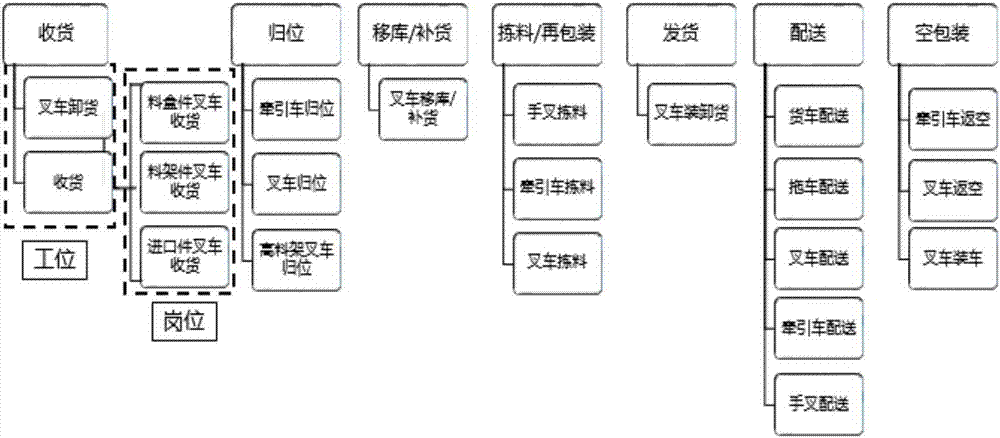

[0022] Such as figure 1 As shown, a standard configuration method of equipment in automobile logistics and warehousing is carried out in accordance with the following steps:

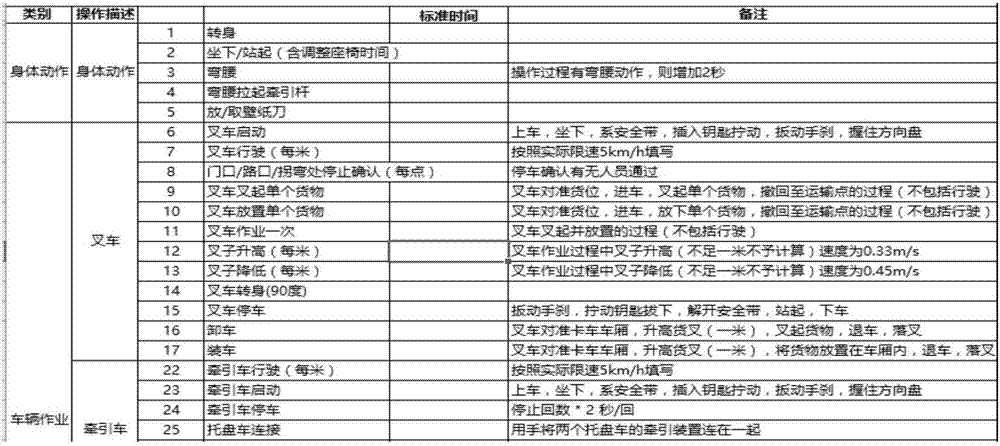

[0023] Step 1. Standard time setting:

[0024] Correctly setting the standard time is the prerequisite to ensure the normal operation of the equipment. All the actions involved in the operation process of logistics equipment are classified, decomposed, arranged and summarized to obtain the smallest action unit structure, and the logistics operation actions are decomposed into the smallest unit action according to forklift action, tractor action, manual operation, visual action, etc., as shown in the table 1 shows:

[0025] Table 1: Minimum unit action table

[0026]

[0027] The standard time modularization method is as follows: us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com