Seedling avoiding weeding device for intertillage stage corn field

A field and corn technology, which is applied in the field of weeding and avoiding seedlings in corn fields during intertillage, can solve the problems of high labor intensity, low operation efficiency, environmental pollution and other problems of manual weeding, and achieve the problem of difficult weeding between plants, low operating costs, and reduced The effect of injury rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

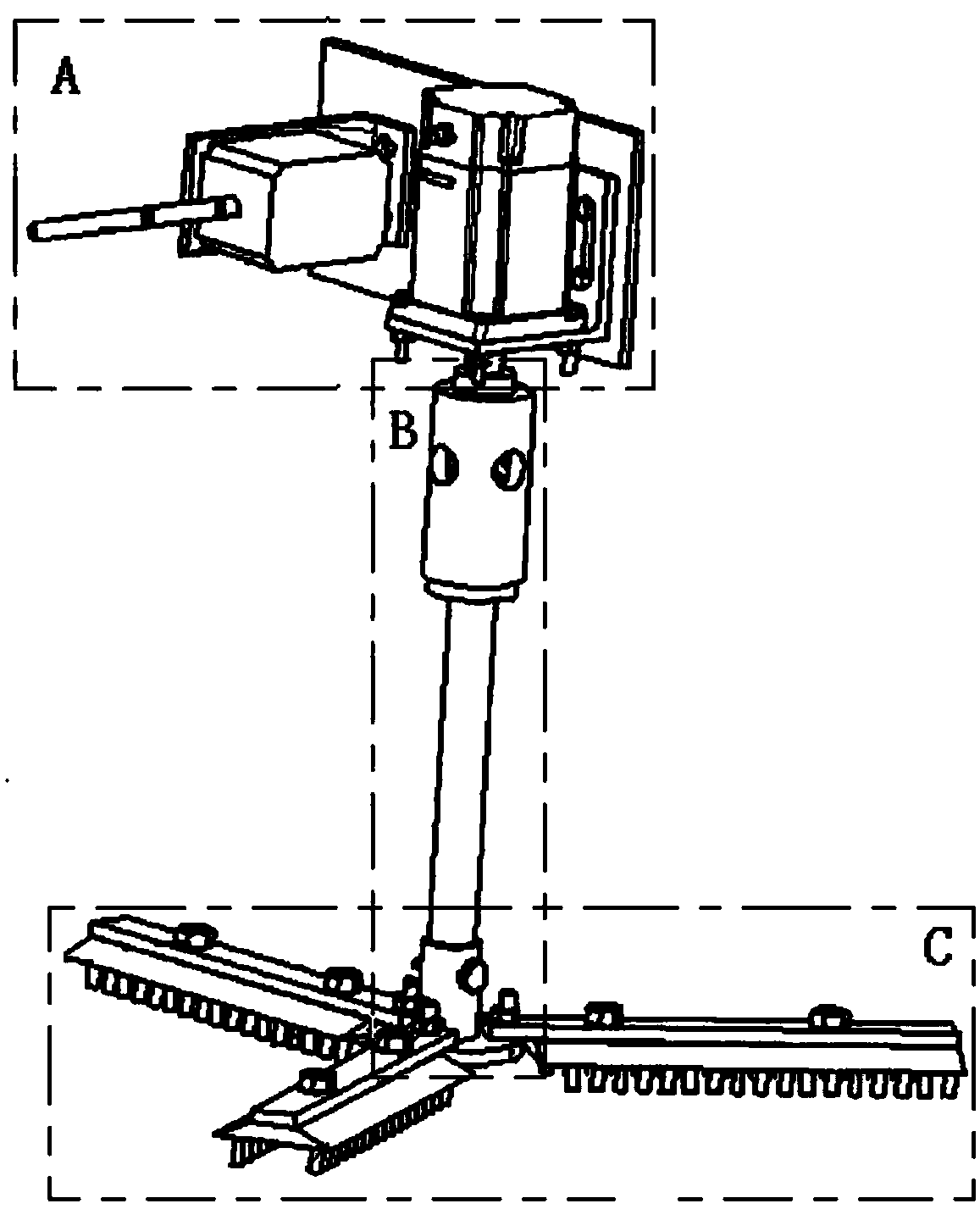

[0033] Such as figure 1 Shown, the present invention is made up of driving device A, connecting rod assembly B and weeding part C, wherein

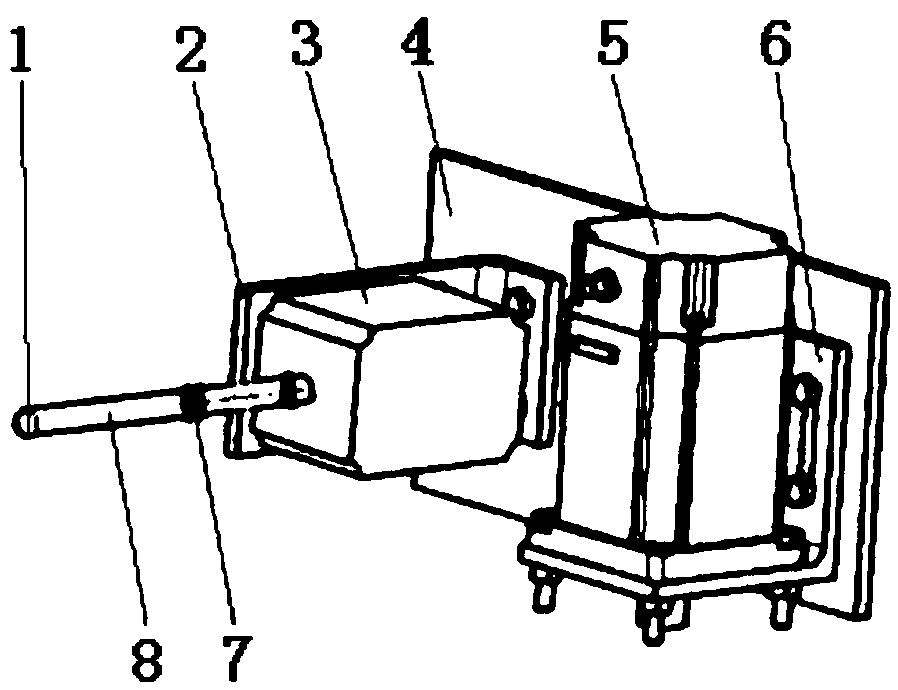

[0034] Such as figure 2 As shown, the drive device A is composed of a vertical right-angle plate 2, a travel switch 3, a mounting plate 4, a stepping motor 5, and a horizontal right-angle plate 6, wherein a vertical surface of the vertical right-angle plate 2 is fixed on the installation On the left side of the board 4, the other facade of the vertical right-angle board 2 is fixedly connected with the travel switch 3, and the travel switch 3 is equipped with a flexible shaft 1, and the flexible shaft 1 is bonded by a spring 7 and a rubber 8; The facade is affixed to the right part of the mounting plate 4, and the horizontal surface of the horizontal rectangular plate 6 is affixed to the stepper motor 5;

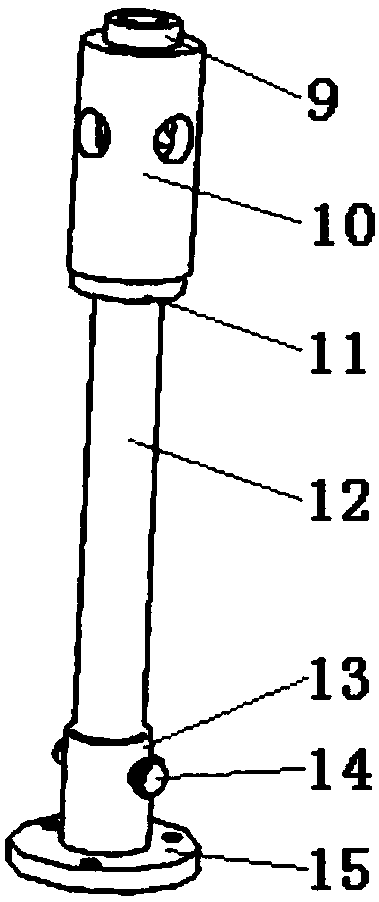

[0035] Suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com