Food processor

A food cooking machine and material technology, applied in the field of food cooking machines, can solve the problems of low crushing and grinding efficiency, insufficient texture of food materials, single food processing methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

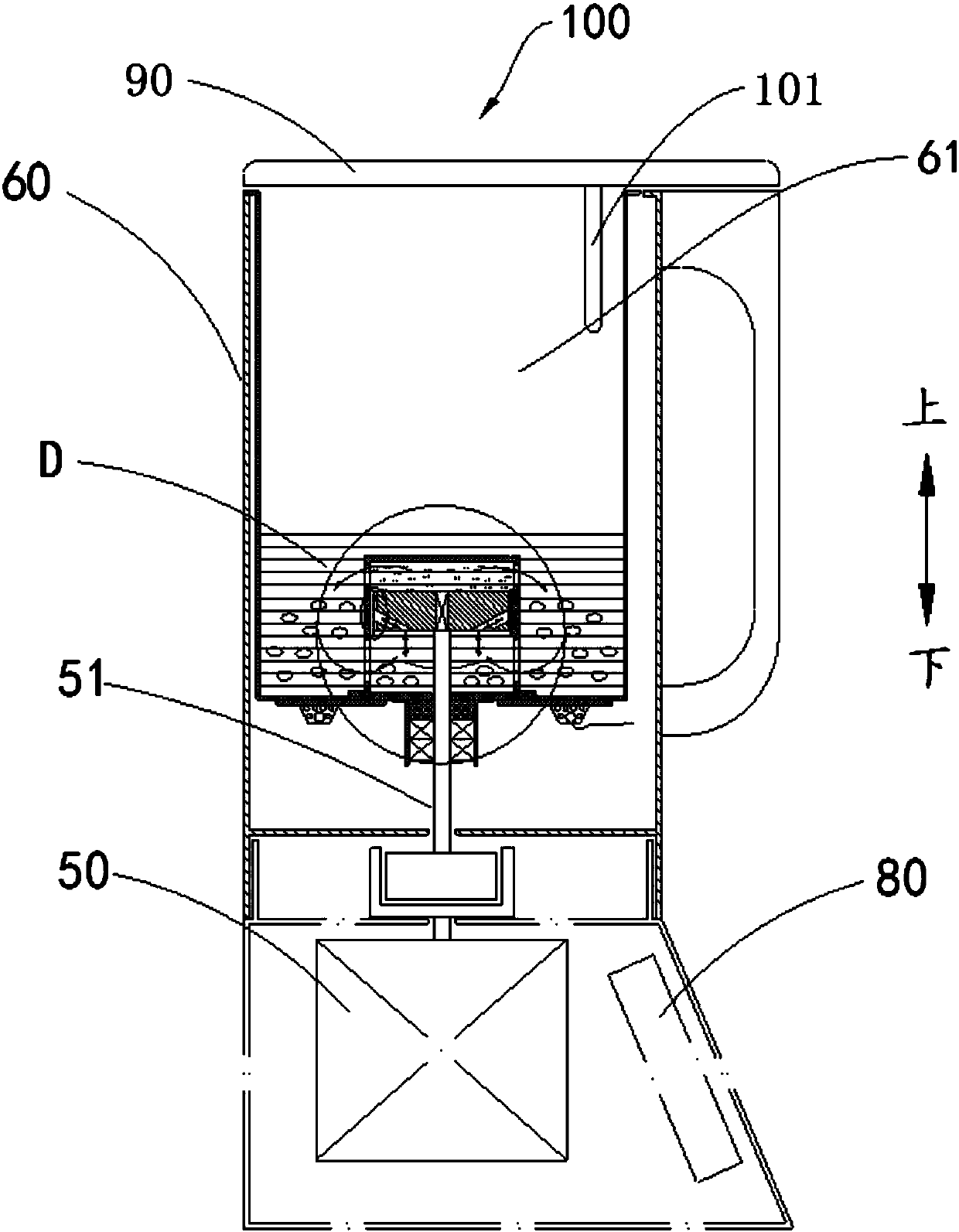

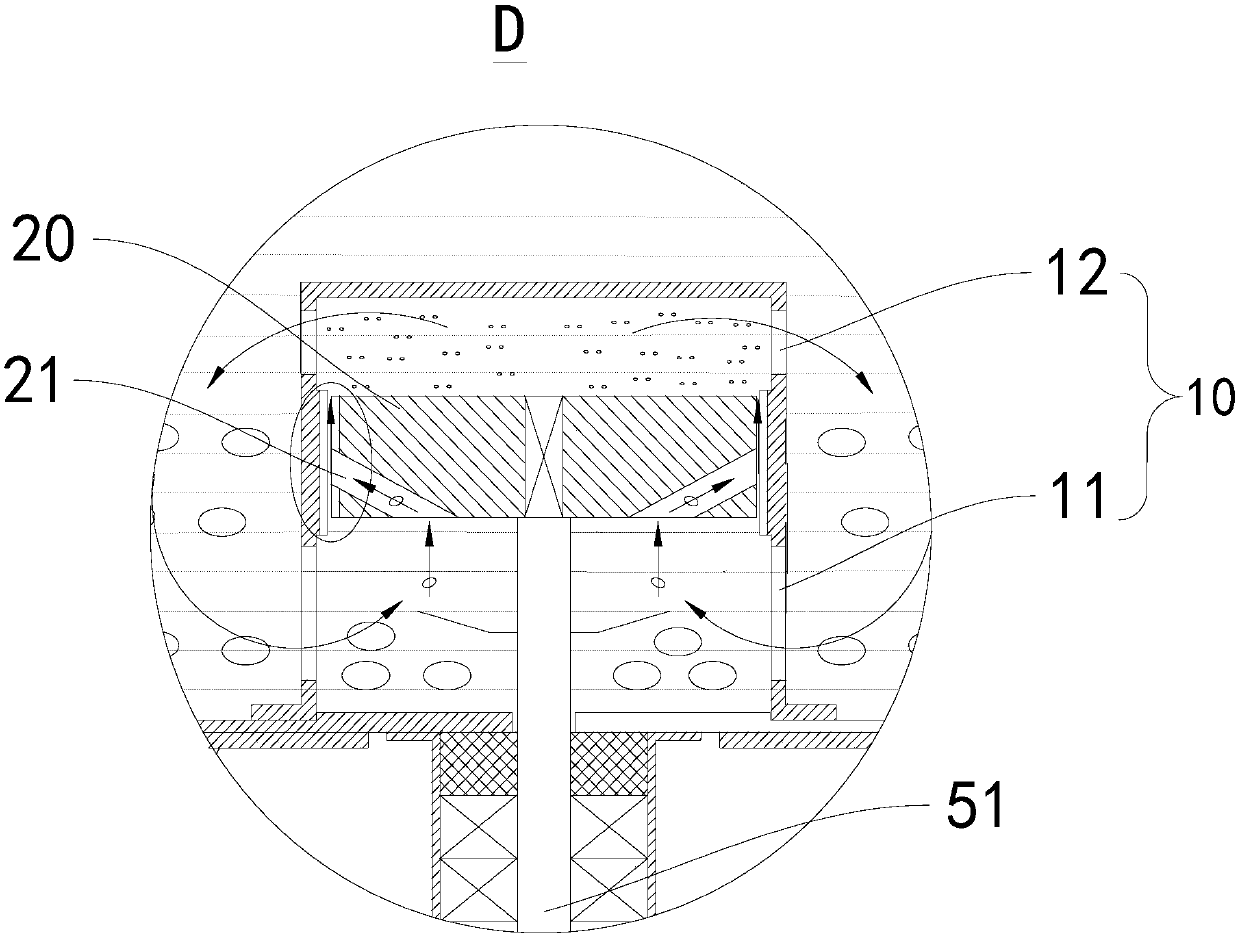

[0070] Embodiment one, such as figure 1 and figure 2 As shown, the food cooking machine 100 may include: a bucket body 60 , a machine base 70 , a static grinding cover 10 , a dynamic grinding head 20 , a blade 40 and a driving device 50 . Wherein, the driving device 50 may be a bottom-mounted driving motor.

[0071] Specifically, the driving device 50 is disposed on the base 70 . The barrel body 60 rests on the machine base 70. There is a crushing and grinding chamber 61 in the barrel body 60. The barrel body 60 is provided with a driving shaft 51 connected to the driving device 50. The driving shaft 50 extends in the vertical direction and at least a part is located in the crushing and grinding chamber. Within 61. The static grinding cover 10 is arranged in the crushing and grinding chamber 61 , and the static grinding cover 10 is formed with a feed port 11 and a discharge port 12 arranged at intervals up and down. The dynamic grinding head 20 is connected with the drive...

Embodiment 2

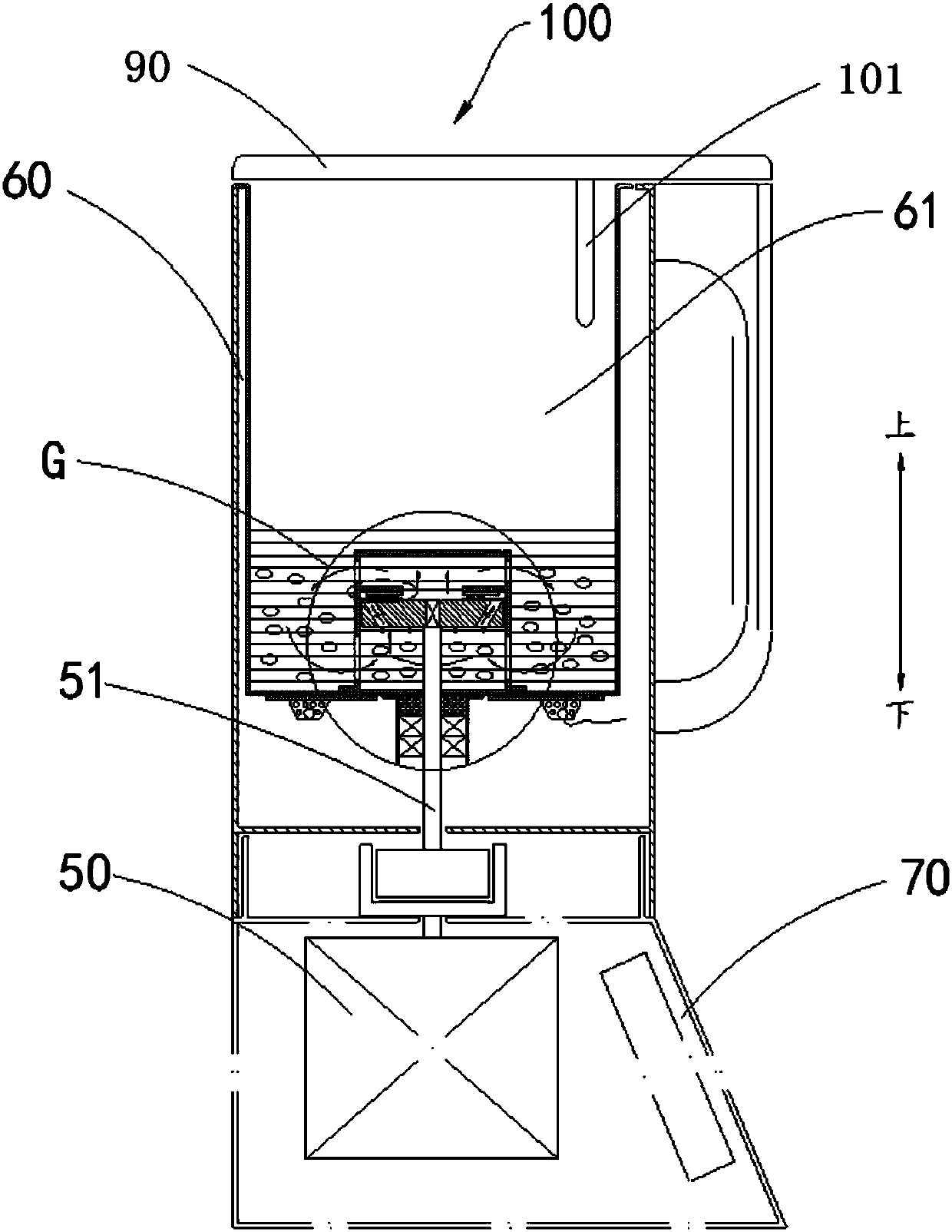

[0076] Embodiment two, such as image 3 and Figure 4 As shown, the food cooking machine 100 may include: a bucket body 60 , a machine head 70 , a static grinder cover 10 , a dynamic grinder 20 , a blade 40 and a driving device 50 . Wherein, the driving device 50 may be a top-mounted driving motor.

[0077] Different from Embodiment 1, the static grinding cover 10 also includes an end plate 14, the end plate 14 is arranged horizontally and its outer peripheral edge is connected with the peripheral wall of the annular plate 13, and the end plate 14 is arranged on the upper end of the static grinding cover 10, and the dynamic grinding head The upper end surface of 20 cooperates with the end plate to define a grinding area 30 . The feed port 11 of the static grinding cover 10 is located at the lower end, and the end plate 14 is provided with a through hole, which communicates with the discharge port 12 of the static grinding cover 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com