Food processor

A food processing machine and material technology, applied in the field of food processing machines, can solve the problems of low pulverization and grinding efficiency, single processing method of food materials, and insufficient taste of food materials, etc., and achieves the effect of speeding up the flow rate and avoiding clogging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

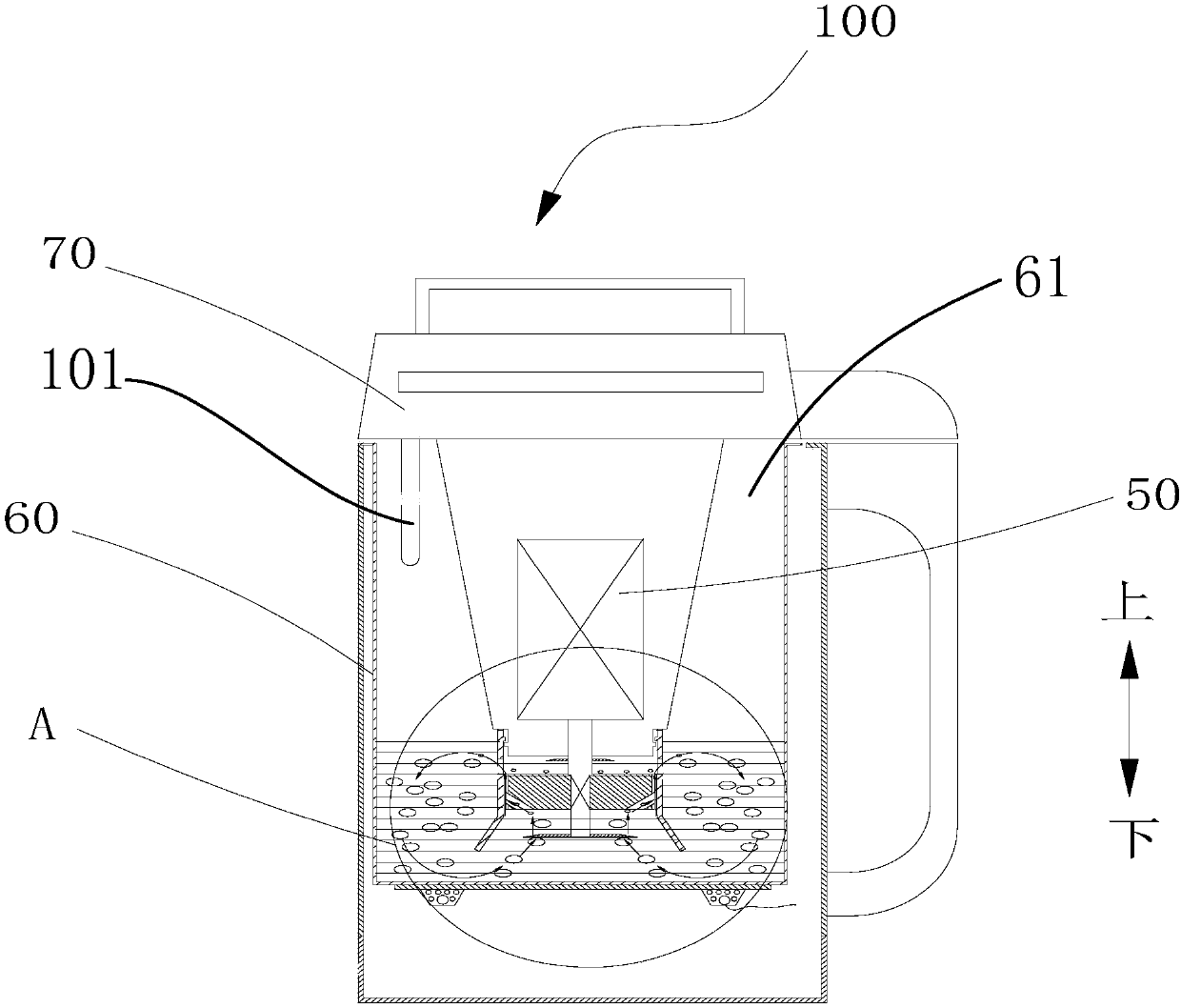

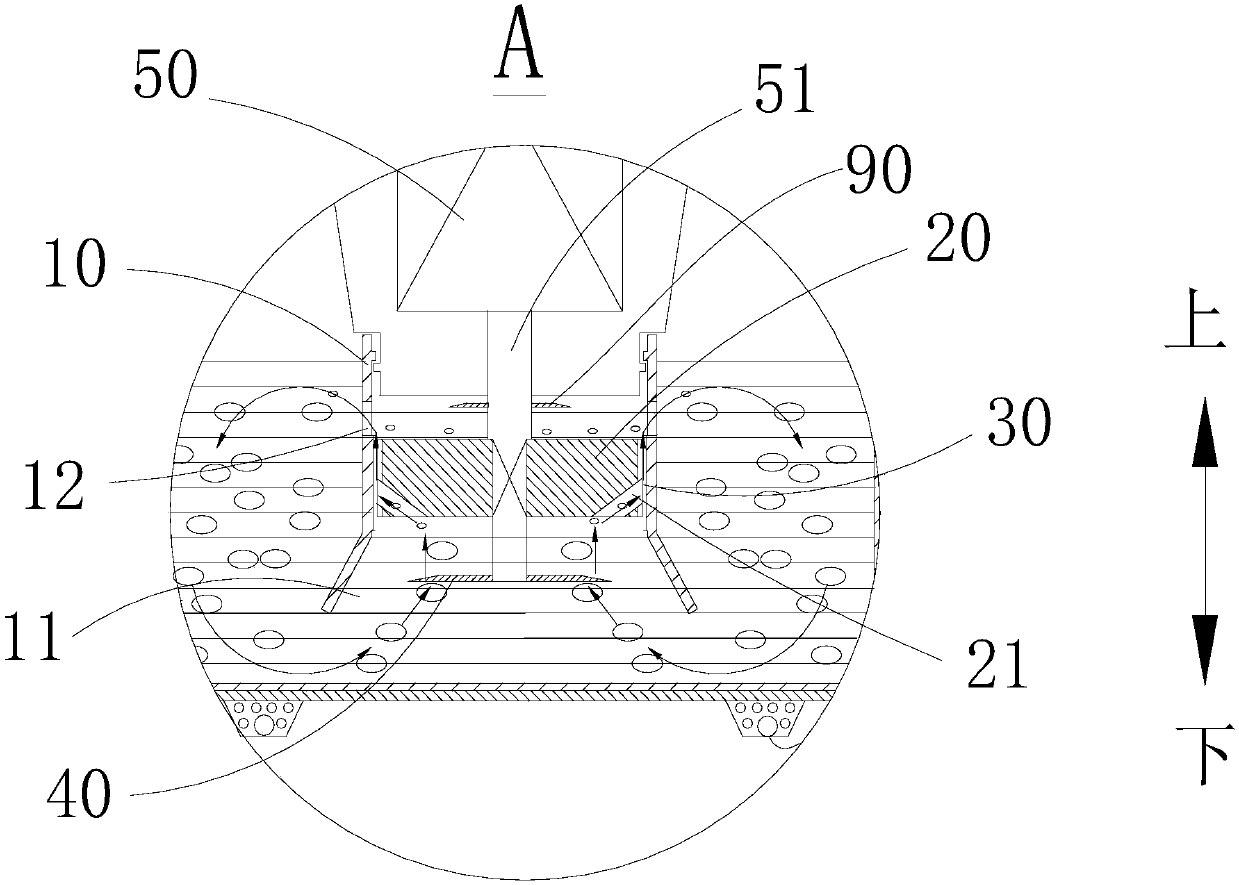

[0086] Embodiment one, such as figure 1 and figure 2 As shown, the food cooking machine may include: a static grinding cover 10 , a dynamic grinding head 20 , a blade 40 , a driving device 50 and an auxiliary pulping blade 90 . Wherein, the driving device 50 is a top-mounted driving motor.

[0087] Specifically, a feeding port 11 and a feeding port 12 arranged at intervals up and down are formed on the static grinding cover 10 . The dynamic grinding head 20 is arranged inside the static grinding cover 10 and is located between the feed port 11 and the discharge port 12 , and a grinding area 30 for grinding materials is defined between the moving grinding head 20 and the static grinding cover 10 . The blade 40 and the movable grinding head 20 are spaced apart in the vertical direction, and the blade 40 is located at the feeding side of the movable grinding head 20 for pulverizing materials. The driving device 50 is respectively connected with the blade 40 and the movable gr...

Embodiment 2

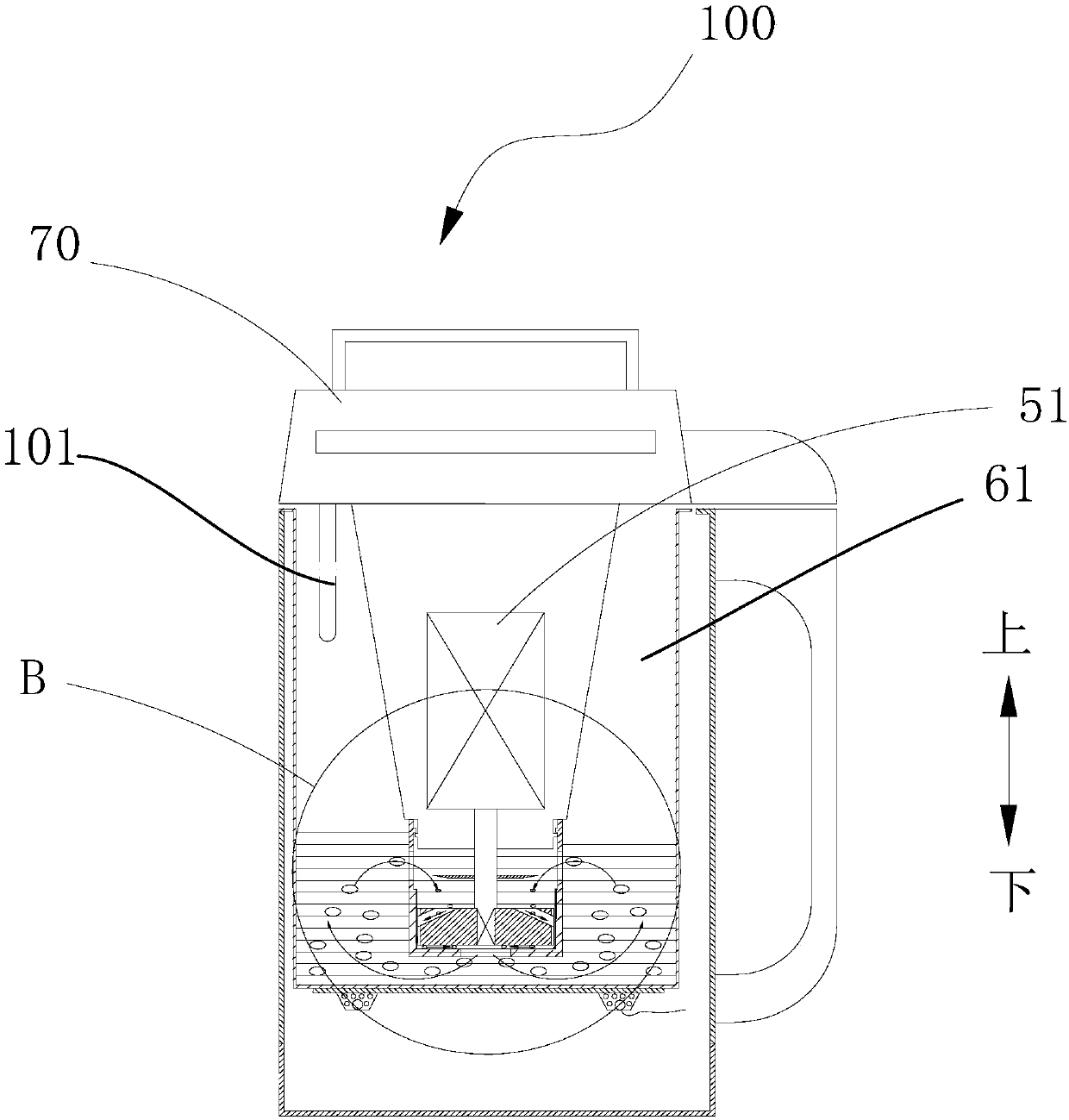

[0102] Embodiment two, such as image 3 and Figure 4 As shown, the food cooking machine 100 may include: a static grinding cover 10 , a dynamic grinding head 20 , a blade 40 and a driving device 50 . Wherein, the driving device 50 is a top-mounted driving motor. The difference between the first embodiment and the second embodiment is that the blade 40 is located above the dynamic grinding head 20 , and the auxiliary pulp discharge blade 90 is not provided on the driving device 50 .

Embodiment 3

[0103] Embodiment three, such as Figure 5 and Figure 6 As shown, the food cooking machine 100 may include: a static grinding cover 10 , a dynamic grinding head 20 , a blade 40 , a driving device 50 and an auxiliary pulping blade 90 . The difference between Embodiment 3 and Embodiment 1 is that the drive device 50 is a bottom-mounted drive motor, the lower end of the static grinding cover 10 is connected to the machine base 80 , and the auxiliary pulp discharge blade 90 is arranged below the dynamic grinding head 20 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com