Temperature monitoring processing method of battery management system based on function safety

A battery management system and functional safety technology, applied in battery/fuel cell control devices, electric vehicles, vehicle energy storage, etc., can solve problems such as lack of battery pack temperature, functional diagnosis and monitoring, and achieve reliable operation and personal protection safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

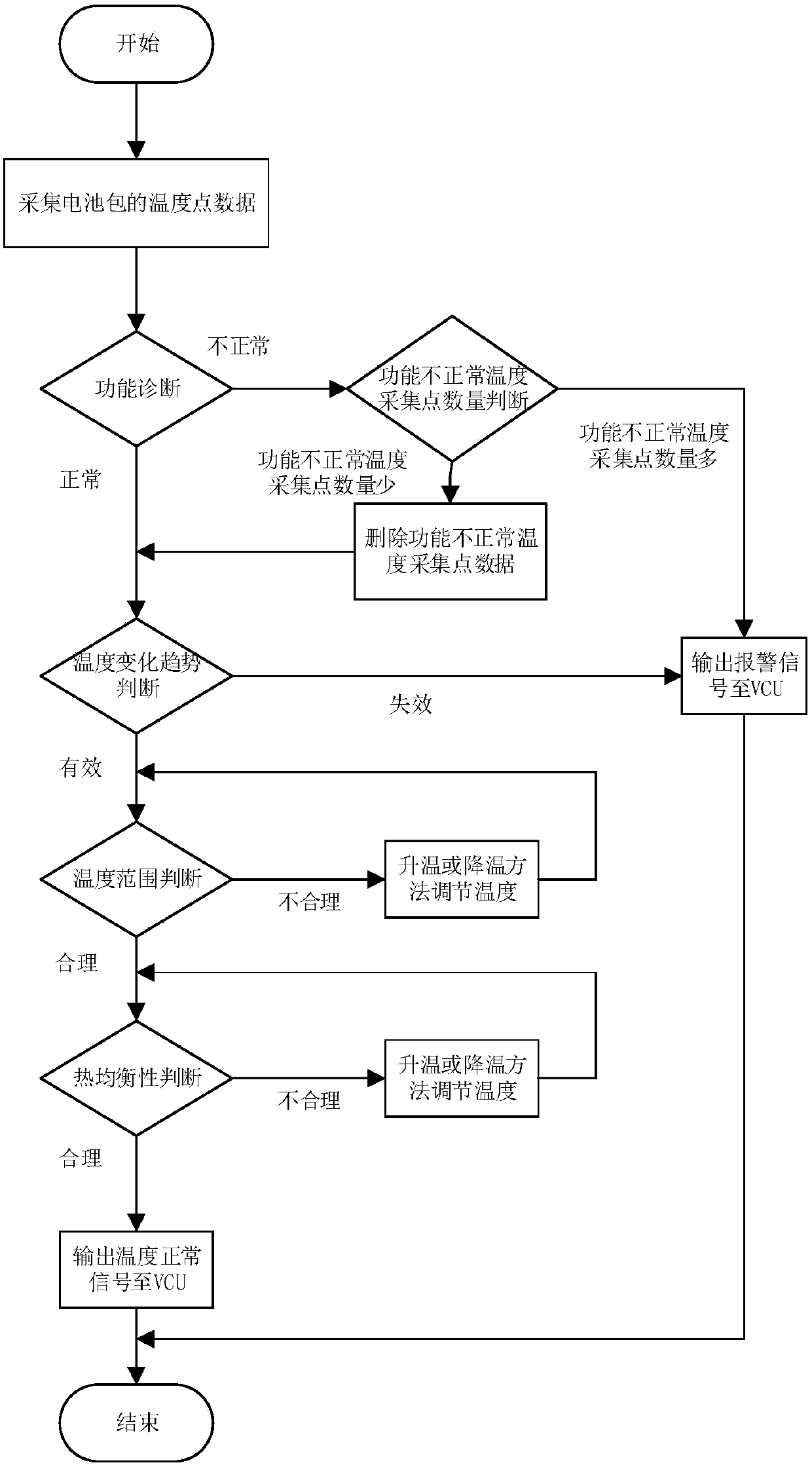

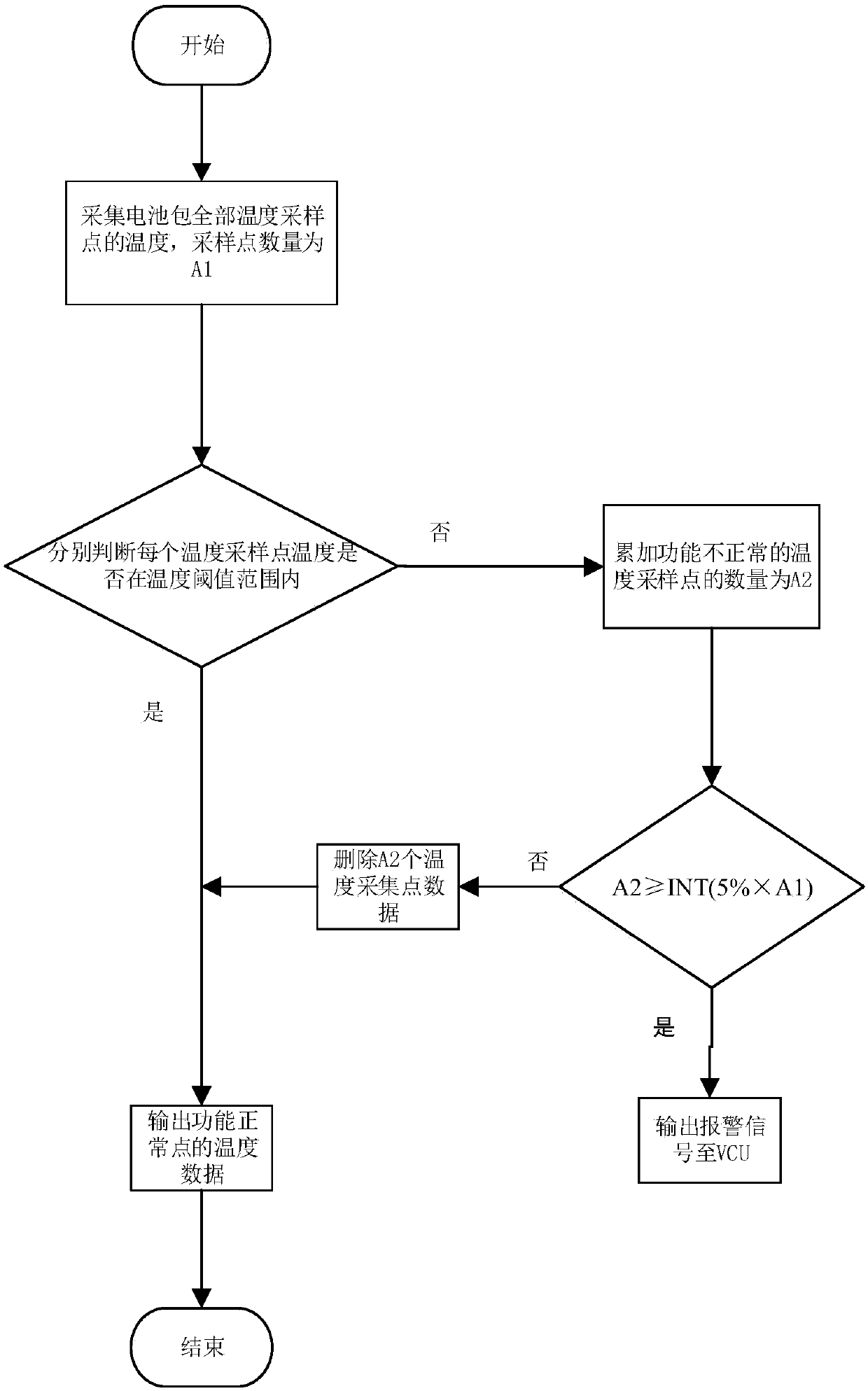

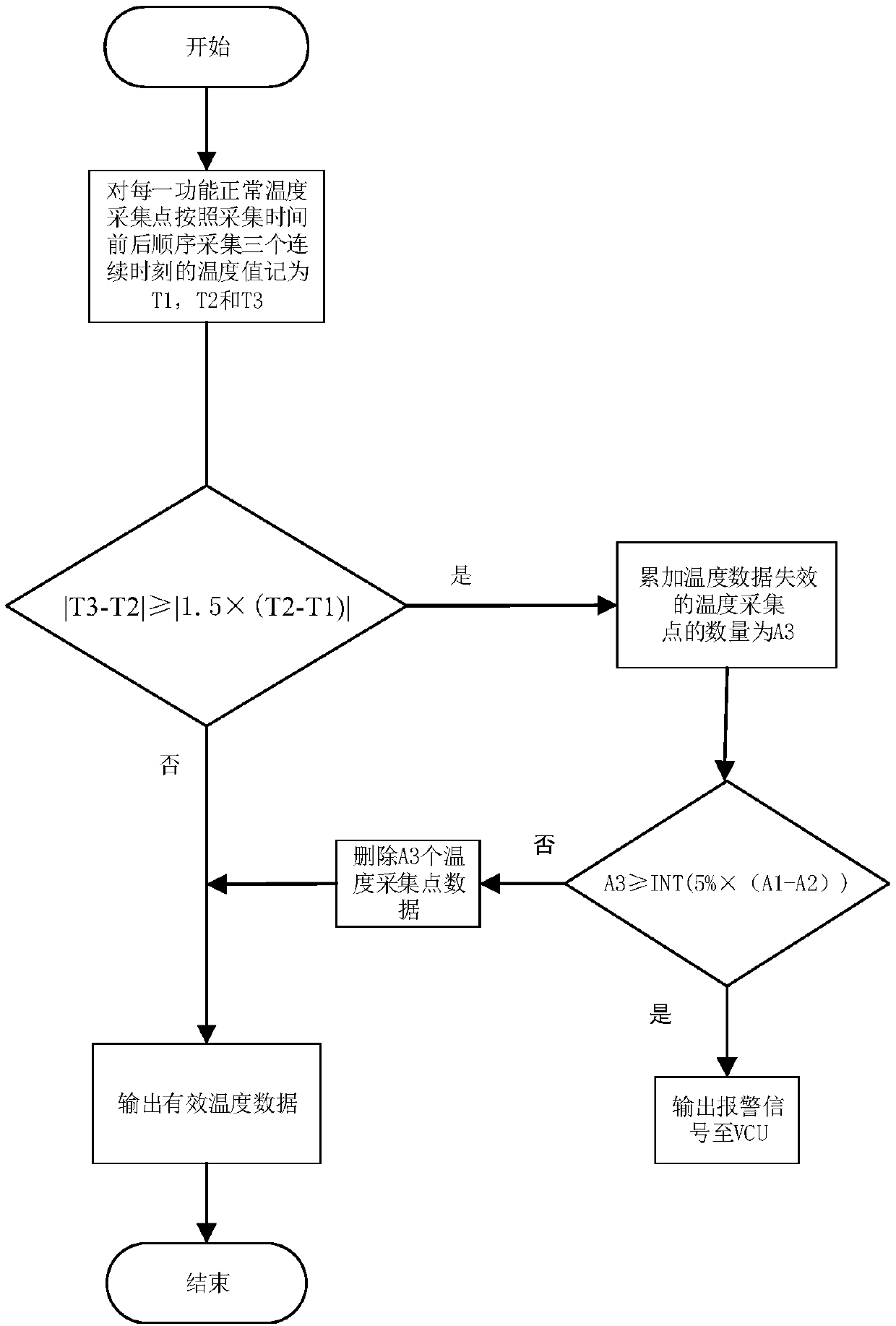

[0021] The design idea of a battery management system temperature monitoring and processing method based on functional safety in the present invention is that the method based on the concept of functional safety of diagnosis and monitoring can be used to diagnose the sampling point with abnormal temperature sampling function, and monitor and judge the temperature change with time The rationality of the trend, judging whether the temperature is within the working temperature range, and judging the thermal balance of the temperature at each point of the battery pack. When overtemperature, low temperature, etc. exceed the normal operating temperature range or the thermal bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com