Lightweight flange PVC conveyor belt

A conveyor belt, light-weight technology, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of conveying failure, drop, single function of conveyor belt, etc., to achieve improved service life, reasonable structure, and novel design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

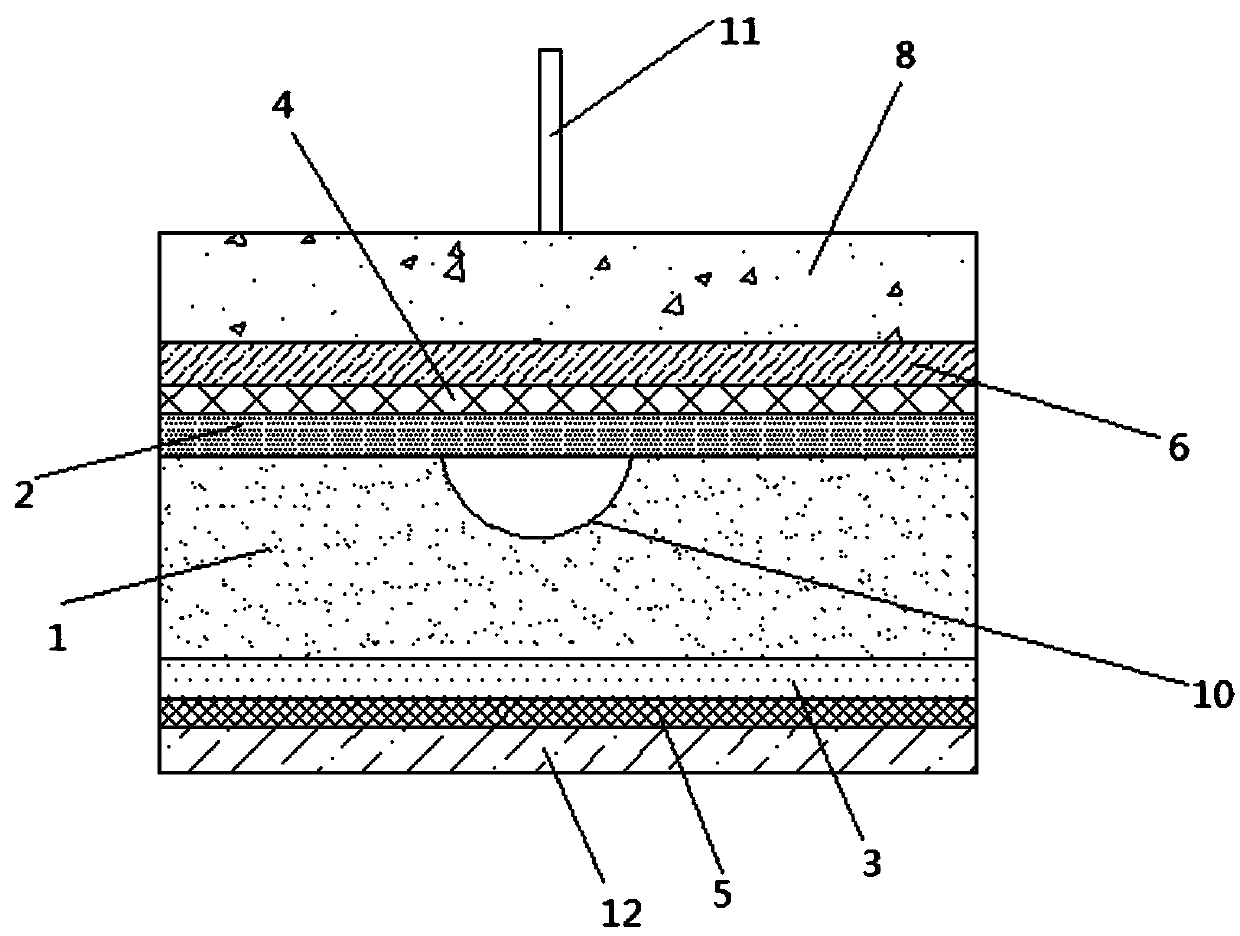

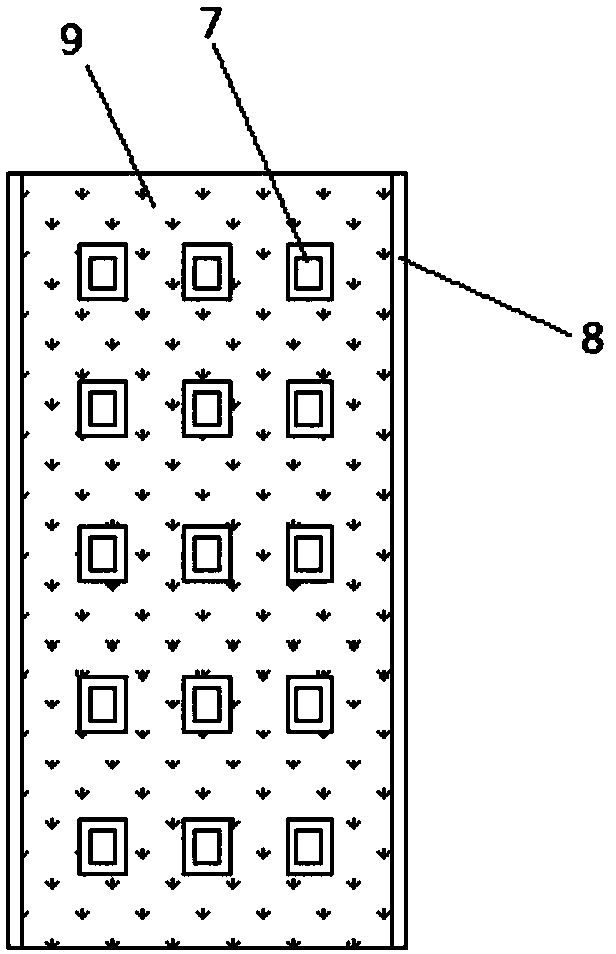

[0014] Refer to attached Figure 1-2 , the present invention provides a light-duty sidewall PVC conveyor belt, which includes a conveyor belt body and a detection device. The conveyor belt body includes a fabric layer 1, and a plurality of steel wires are inserted in the fabric layer 1. The sides are respectively coated with a first adhesive layer 2 and a second adhesive layer 3, the upper surface of the first adhesive layer 2 is provided with a first wear-resistant layer 4, and the lower surface of the second adhesive layer 3 is provided with a second Two wear-resistant layers 5, the upper surface of the first wear-resistant layer 4 is provided with a first rubber layer 6, and the surface of the first rubber layer 6 is provided with colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com