Detachable prestress anchor cable

A technology of prestressed anchor cables and anchor cables, applied in construction, sheet pile walls, foundation structure engineering, etc., can solve the problems of affecting the recovery rate, easy damage of wires, and influence of wires, etc., achieves convenient processing and installation, and reduces engineering costs , Recycling force and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The construction of the present invention includes: foundation pit earthwork excavation and drilling into holes, anchor cable installation, grouting maintenance, tension locking, information monitoring, and anchor cable recovery, specifically including the following steps:

[0019] (1) Foundation pit excavation and drilling

[0020] Excavate the earthwork of the foundation pit to the anchor cable construction operation surface, use a drilling rig to drill a hole in the soil, the hole diameter is 130mm~300mm, the drilling angle deviation is ≯1°, the height difference is ≯50mm, and the hole depth is the design depth +300mm~500mm mm.

[0021] (2) Anchor cable installation

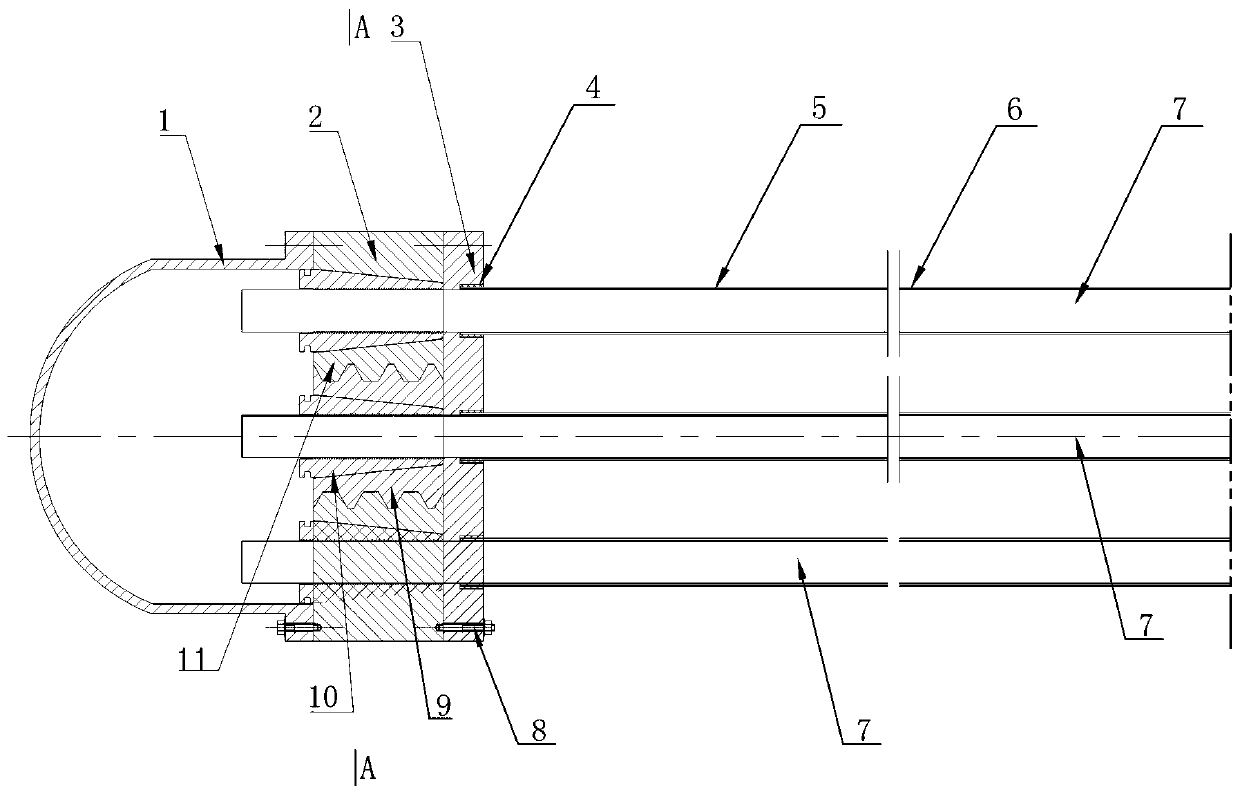

[0022] Place the inner anchor head closed by the sealing cap 1 and the baffle plate 3 at the designed depth position in the completed anchor hole. When the sealing cap 1 penetrates into the bottom of the anchor hole of the anchor cable, pull it out about 500mm to ensure that the end of the anchor head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com