Efficient Cloth Dryer

A dryer and cloth technology, applied in the field of cloth processing, can solve the problems of low drying efficiency, achieve efficient drying, avoid yellow spots, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

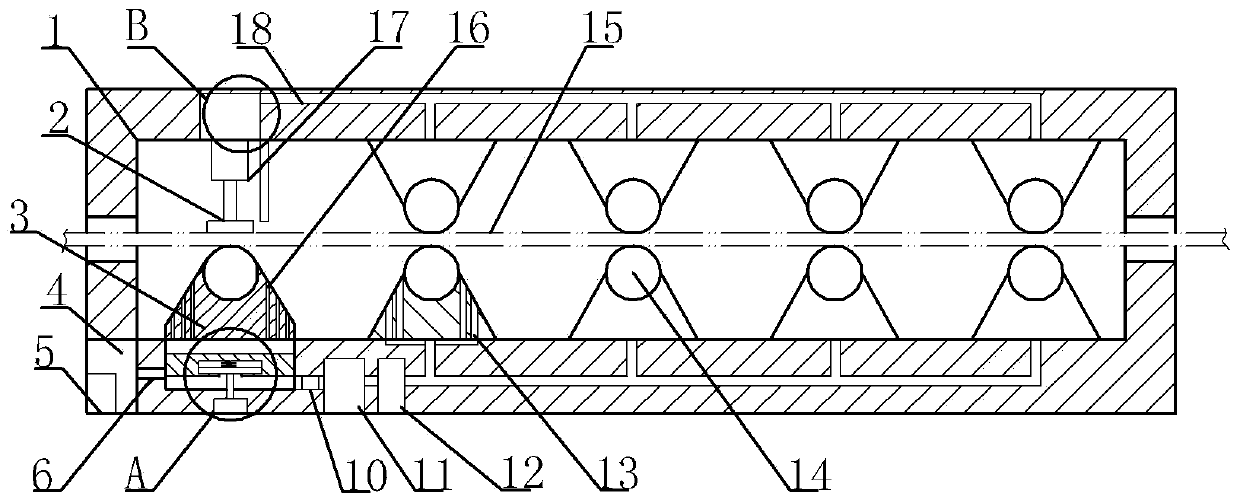

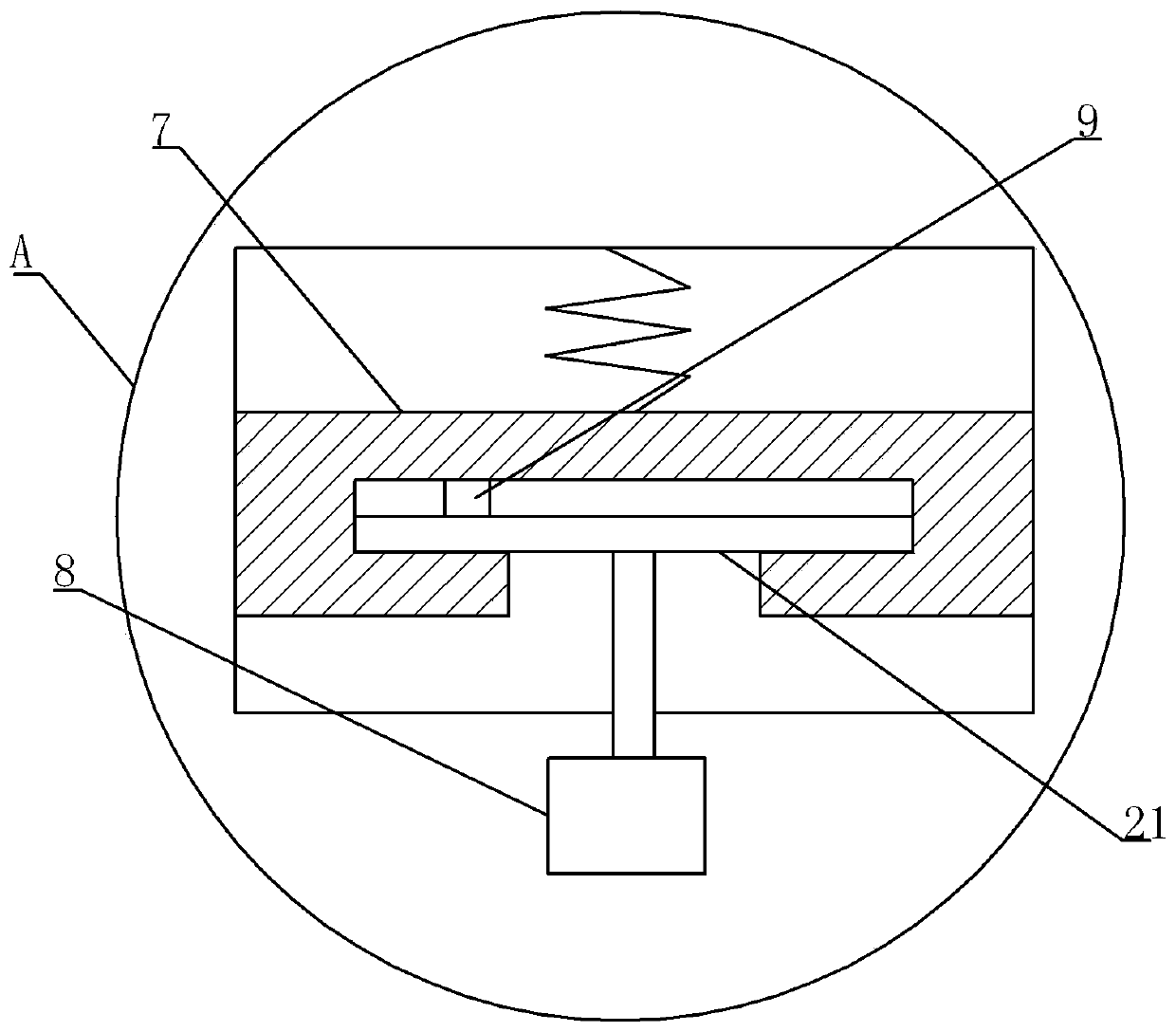

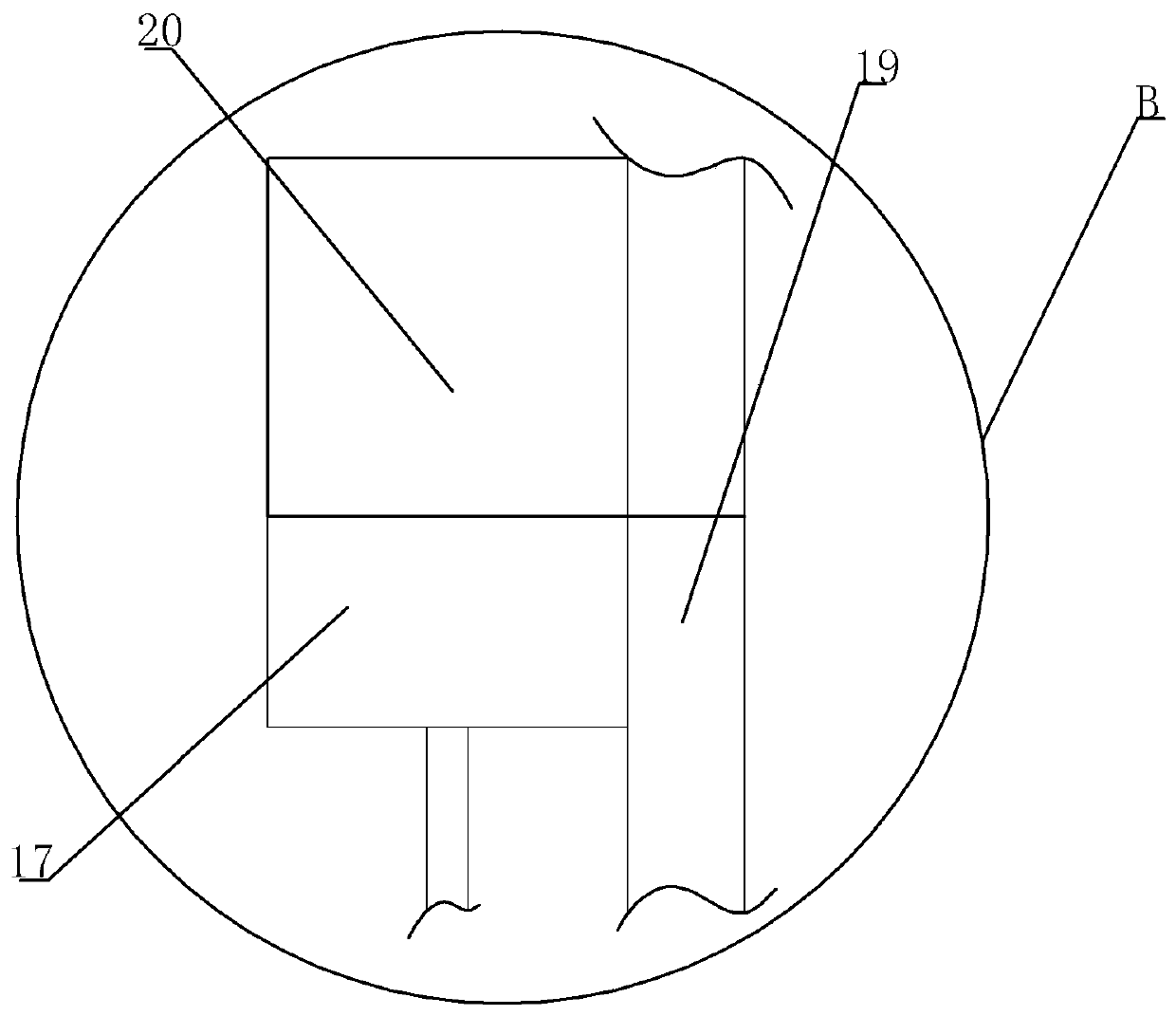

[0021] as attached figure 1 , attached figure 2 And attached image 3 As shown, a high-efficiency cloth dryer includes a drying box 1 with a material inlet and a material outlet. An extruding mechanism is arranged on the side close to the feed inlet in the drying material box 1. The extruding mechanism includes a water inlet cone 3 and an extrusion cylinder. above. A cooling cavity 20 located in the baking material box 1 is arranged above the extruding cylinder. The output shaft of the extrusion cylinder is fixed with a press plate 2 that can compress the cloth 15, and the bottom of the press plate 2 is provided with a hydrophobic layer to prevent the press plate 2 from staining the cloth 15. The water inlet cone 3 is provided with a water inlet 16 and a feed roller, and the feed roller is rotatably connected with the feed cone. The water inlet 16 is located on the slope of the water inlet cone 3. The water delivery chamber communicated with hole 16. When the cloth 15 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com