Fully-automatic piston pressure gauge

A piston pressure gauge, fully automatic technology, applied in the field of precision instruments, can solve problems such as low work efficiency and errors, and achieve the effects of improving accuracy and measurement speed, improving efficiency and accuracy, and improving output accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

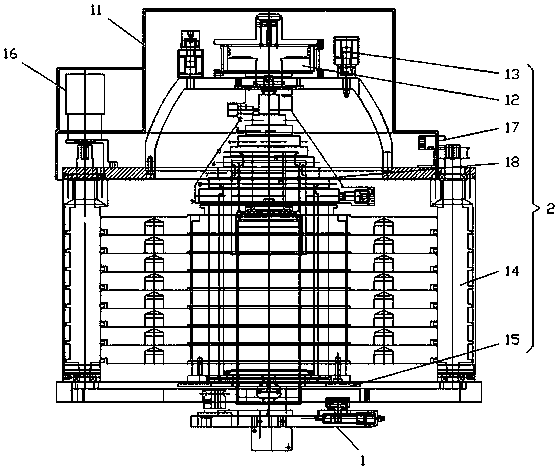

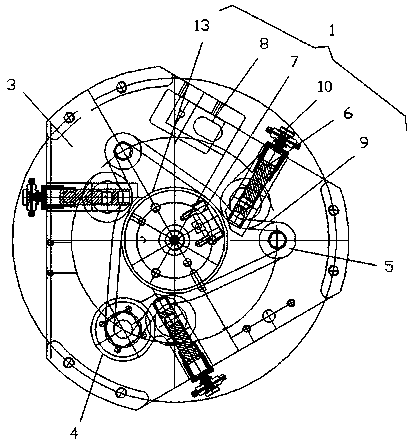

[0015] see Figure 1-2 , the present invention provides a technical solution: a fully automatic piston pressure gauge, comprising a piston rotation system 1 and a weight selection system 2, the piston rotation system 1 is located at the bottom of the weight selection system 2; the piston rotation system 1 Including a base 3, a motor 4, a pulley 5, a piston 6, a speed sensor 7 and a displacement sensor 8, the surface of the base 3 is provided with a pulley 5, and the pulley 5 is located at the center of the base 3 in a triangular shape. Below is provided with motor 4, the output end of described motor 4 is fixedly connected with pulley 5, and belt 9 is arranged between described pulley 5, and the edge of described base 3 is provided with piston 6, and described piston 6 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com