System for assembling electrical cabinets of an electrical switchboard

A technology for assembling systems and electrical cabinets, applied in the field of electrical cabinets, can solve the problems of no longer guaranteeing the performance of electrical cabinets, the solution is not completely satisfactory, reducing the use of nuts and bolts, etc., so as to reduce installation costs and reduce ground clearance. Surface, the effect of speeding up the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Throughout the description, it should be noted that the terms "front", "rear", "top", "bottom", "vertical" and "horizontal" are to be understood as considering the position of the electrical cabinet 2 of the switchboard 10 on the floor during installation. The usual positioning on .

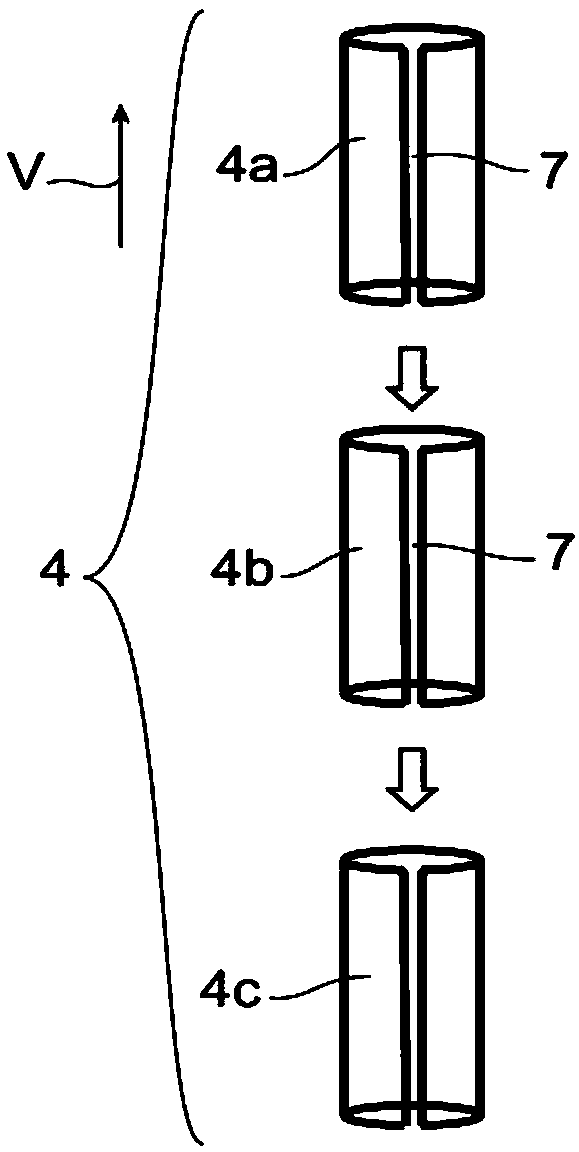

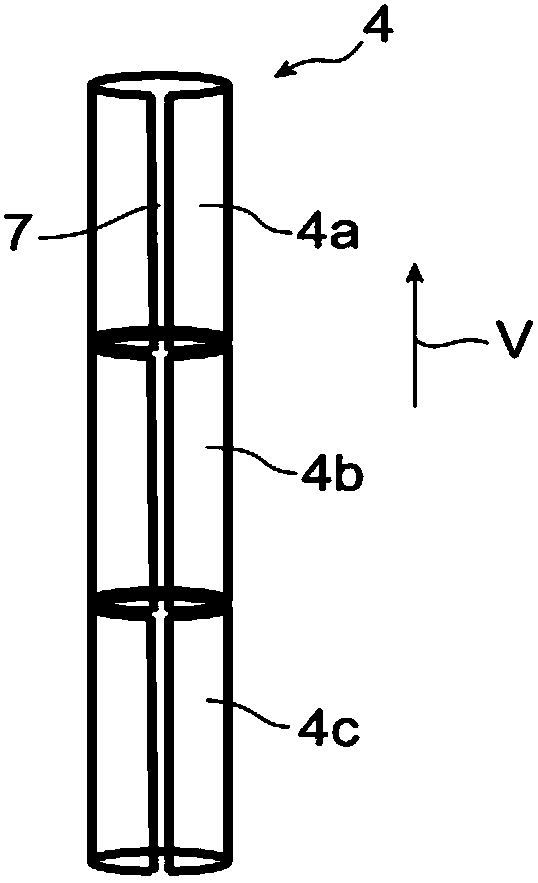

[0047] Also, it should be noted that in Figure 1-3 and 5-7A, the axis H represents the horizontal axis and the axis V represents the vertical axis.

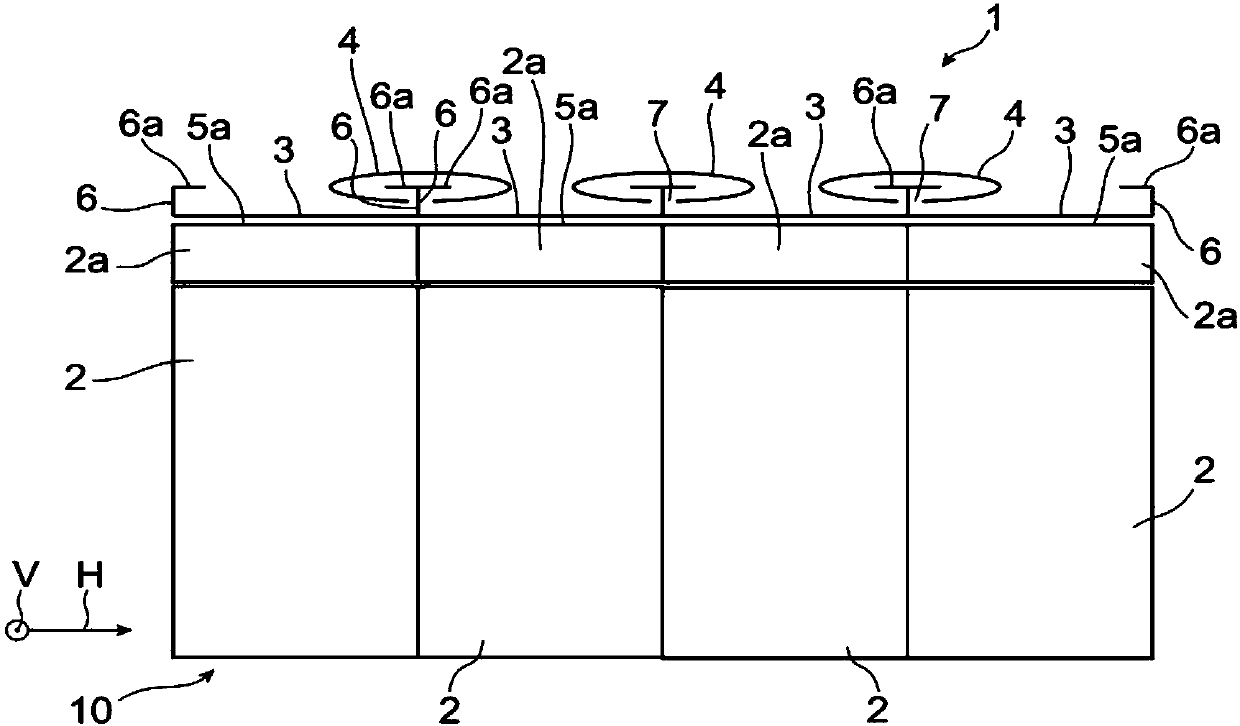

[0048] refer to figure 1 , shows a switchboard 10 comprising four electrical cabinets 2 assembled by means of the assembly system 1 according to the invention.

[0049] According to the invention, the assembly system 1 comprises four metal rear fixing plates 3 . Each rear fixing plate 3 is fixed to the rear side 5 a of the rear portion 2 a of each electrical cabinet 2 .

[0050] Furthermore, each rear fixing plate 3 extends vertically along the rear side 5a of the corresponding electrical cabinet's rear portion 2a and has a substantially C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com