Manufacturing method of waterproof soft plastic packaging box

A production method and packaging box technology, applied to other household appliances, household appliances, applications, etc., can solve the problems of low production efficiency, low degree of automation, and the influence of heat-sealing connection quality staff operations, etc., to achieve high production efficiency, The effect of reducing production cost and fast assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

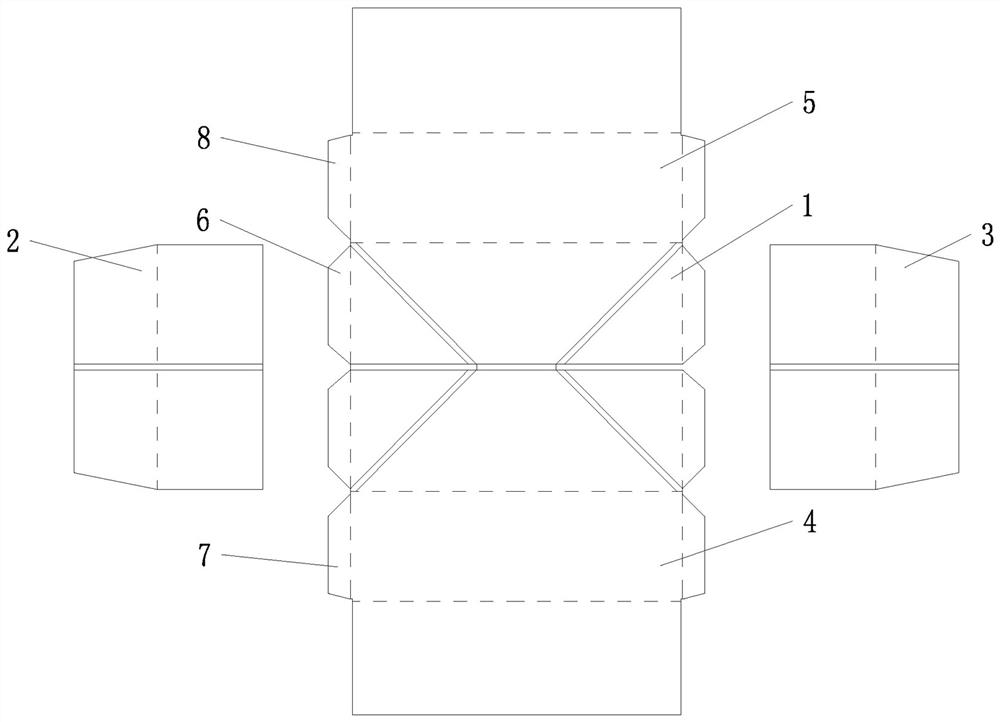

[0024] A kind of manufacture method of waterproof soft plastic packing box, refer to figure 1 , the packing box is divided into bottom plate 1, left side plate 2, right side plate 3, front side plate 4 and rear side plate 5, bottom plate 1, front side plate 4, rear side plate 5 constitute the main board, and the two sides of bottom plate 1 are set There is a first connecting portion 6, a second connecting portion 7 is arranged on both sides of the front side plate 4, a third connecting portion 8 is arranged on both sides of the rear side plate 5, and the left side plate 2 and the right side plate 3 are all cut separately. Cut into shape, the production steps of the packing box are as follows:

[0025] (1) Use a cutting knife to cut the plastic sheet into shape, cut out the main board, left side board, and right side board respectively, and reserve There are first connecting part, second connecting part and third connecting part. The cutting method can be die-cutting. The die-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com