Welding jig for evaporator core

A technology for welding fixtures and evaporator cores, which is applied in welding equipment, manufacturing tools, auxiliary devices, etc., can solve the problems of product quality, complex fixture structure, and high cost, and achieves improved welding process efficiency, simple assembly process, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

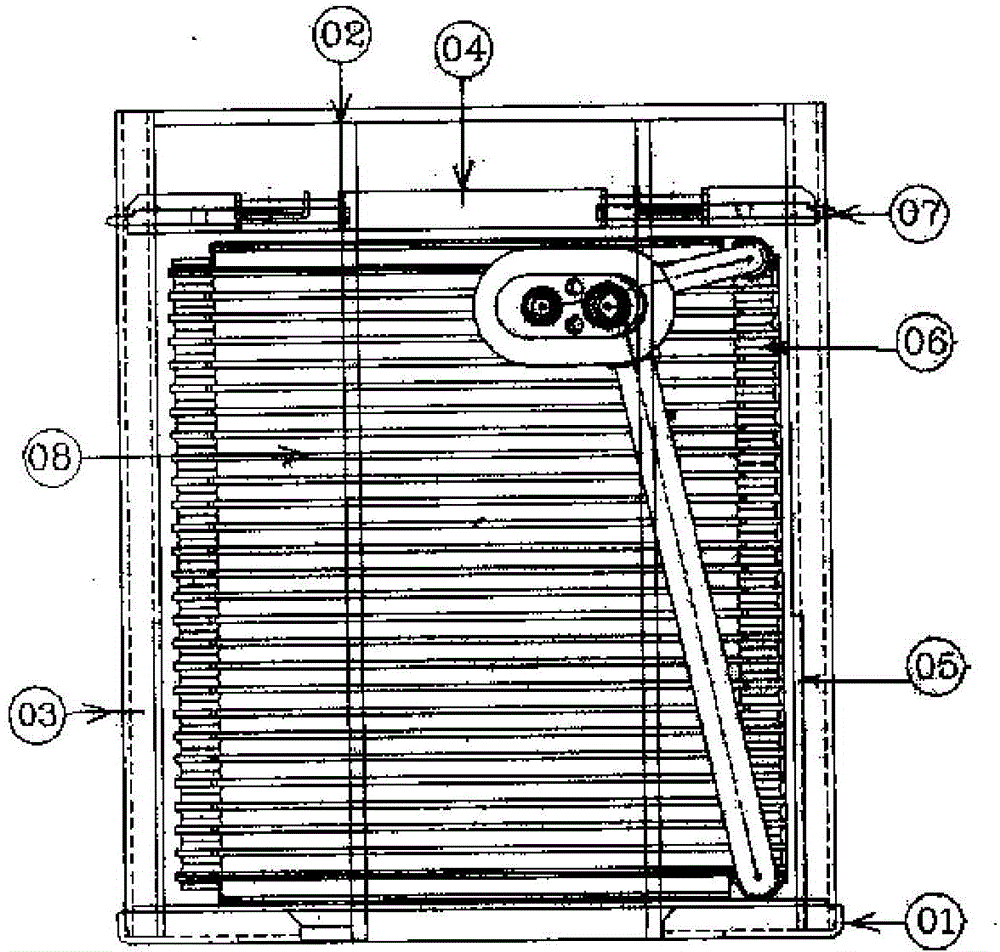

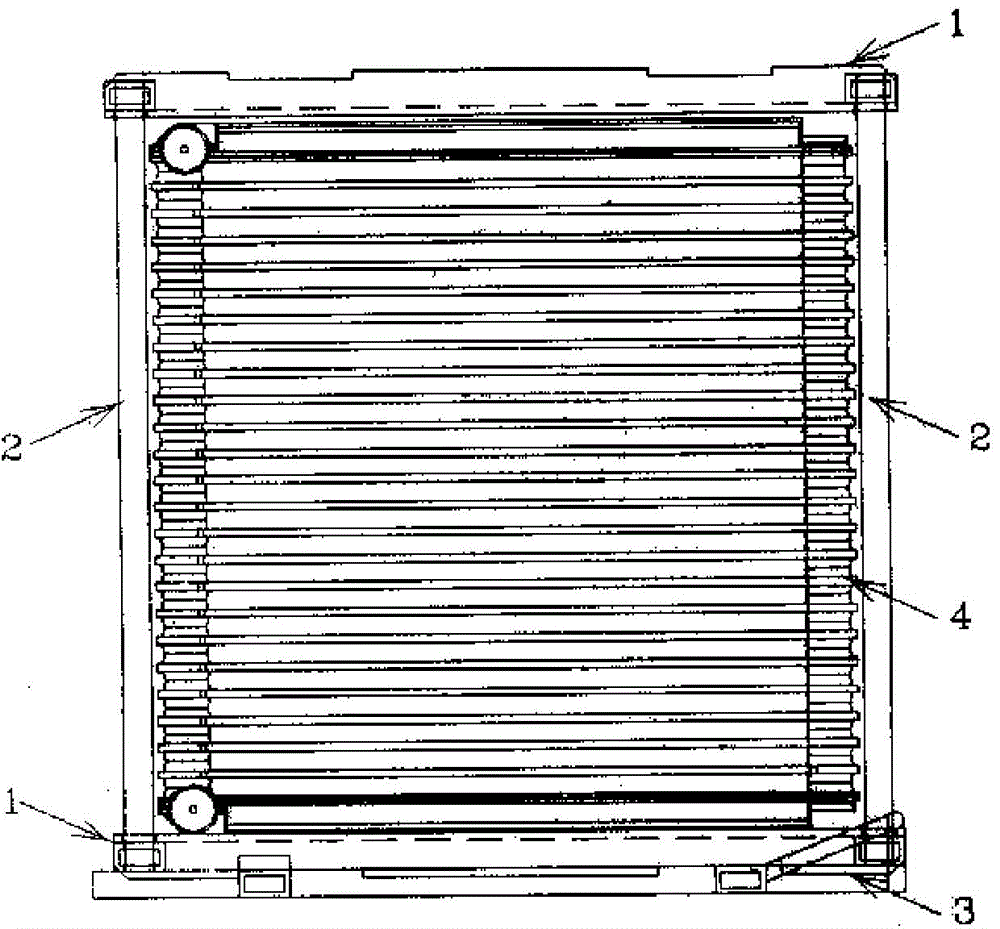

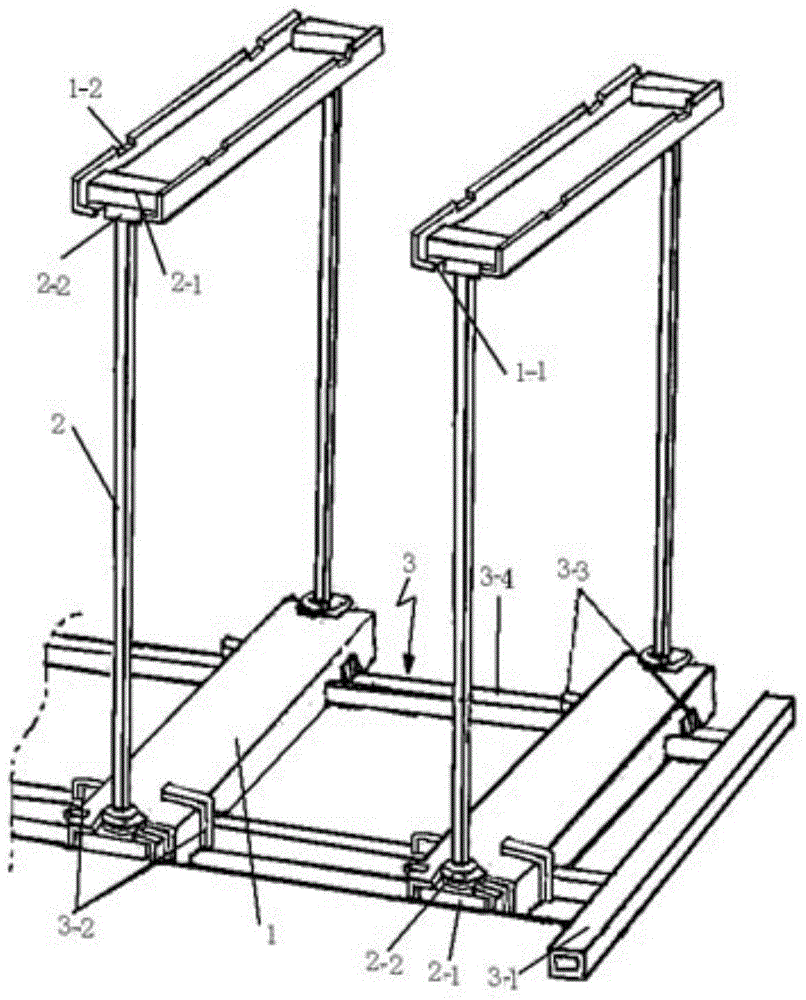

[0013] The present invention proposes a welding jig for an evaporator core. Describe below in conjunction with accompanying drawing.

[0014] exist Figure 2-Figure 5 In the schematic diagram of the new welding fixture shown, the upper and lower cover plates 1 of the welding fixture have the same structure and are made of channel steel. A clamp square opening 1-1 is opened at both ends of the channel steel bottom, and a square opening 1-1 is opened on both sides. Two card slots 1-2 (such as Figure 4 Shown in a, b, c); Wherein the square opening 1-1 of the card bar is put into the connecting card bar 2, and the card slot 1-2 is stuck on the track 3-4 of the base 3, which plays the role of fixing the product. Both sides connecting clip 2 are fixed on connecting clip 2 two ends by upper and lower stopper 2-1 and upper and lower limit ring 2-2 (as Figure 5 As shown), the clips on both sides clamp the upper and lower cover plates and the product to form a whole, and the distan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com