Assembly method and structure of a transformer body

An assembly method and transformer technology, applied in the field of transformers, can solve the problems of large labor intensity, process error of flatness and roundness, long time, etc., to improve the ability to resist short-circuit impact, uniform compression force, and simple assembly process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

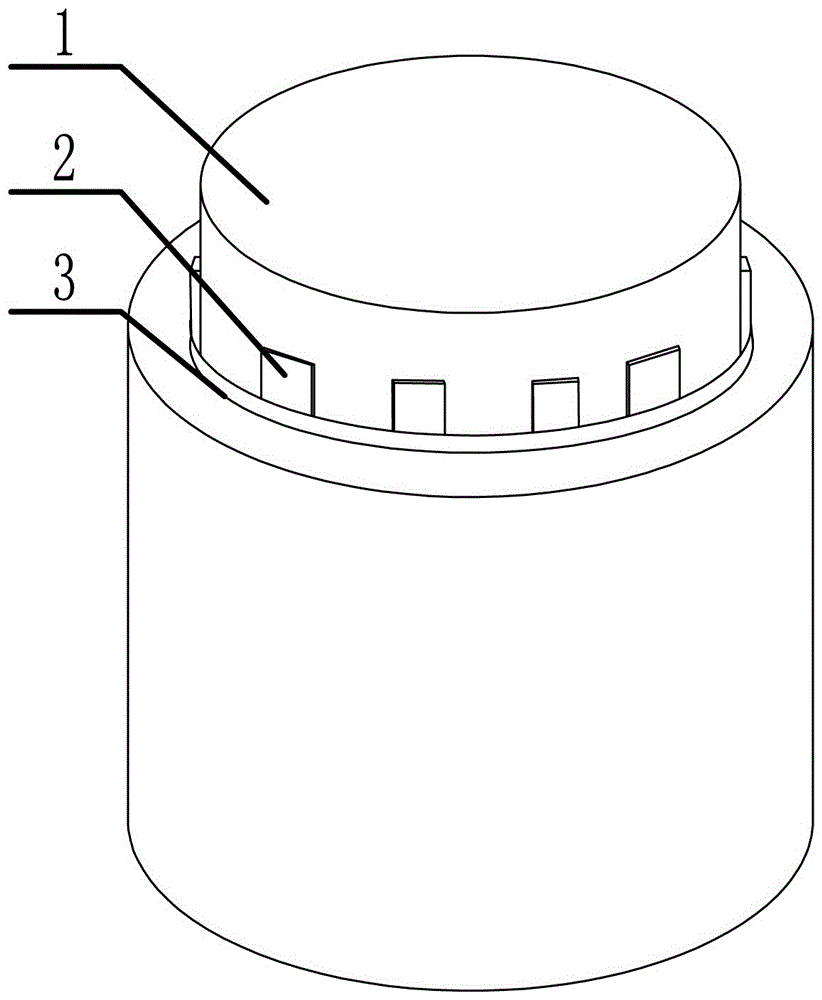

[0017] refer to figure 1 , in the process of assembling the body of the transformer, it is necessary to put the coil on the core 1, insert the stay 2 between the inner side of the coil paper tube 3 and the core column, or insert the coil paper after the core column and the surrounding plate Tube 3, if it is found that the pressure between the coil paper tube 3 and the iron core 1 is not compact enough or the gap is too large, continue to drive in the stay 2. Therefore, the traditional method of assembling the transformer body by means of braces will lead to problems such as low assembly accuracy, difficult assembly, and weak assembly structure.

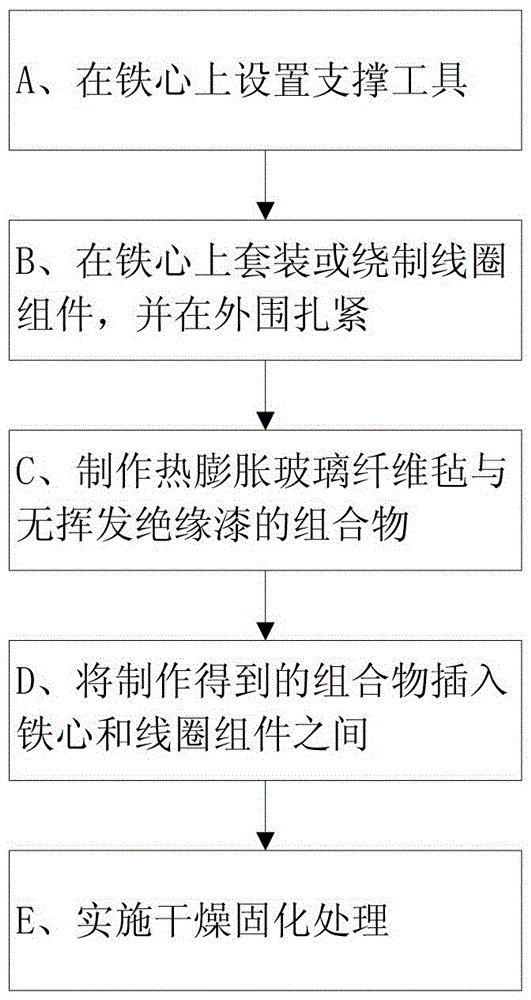

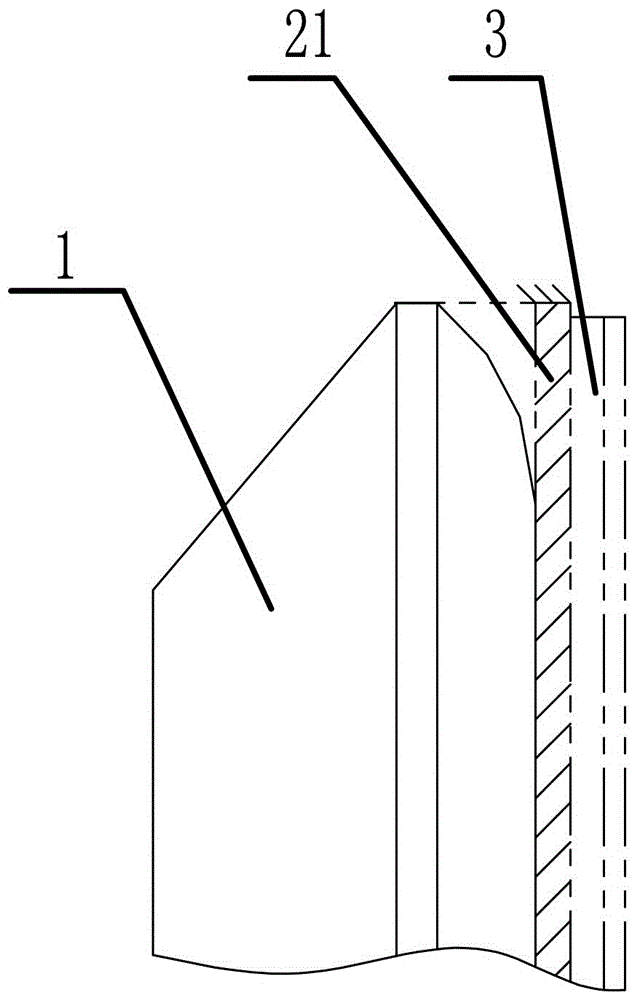

[0018] In an embodiment according to the present invention, a thermally expanded glass fiber mat is soaked in a non-volatile insulating varnish to form a composition, wherein the non-volatile insulating varnish can preferably use a brand of Better 116HU non-volatile insulating varnish. refer to figure 2 with image 3 After the sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com