Liquid-insulated rotary baking curing device and method for armature

A rotary baking, liquid insulation technology, applied in electromechanical devices, laying solid insulation, electrical components, etc., can solve the problem of long dipping time, affecting the amount of paint loss, affecting the amount of paint hanging on the inner and outer surfaces of the secondary dipping iron core, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0170] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

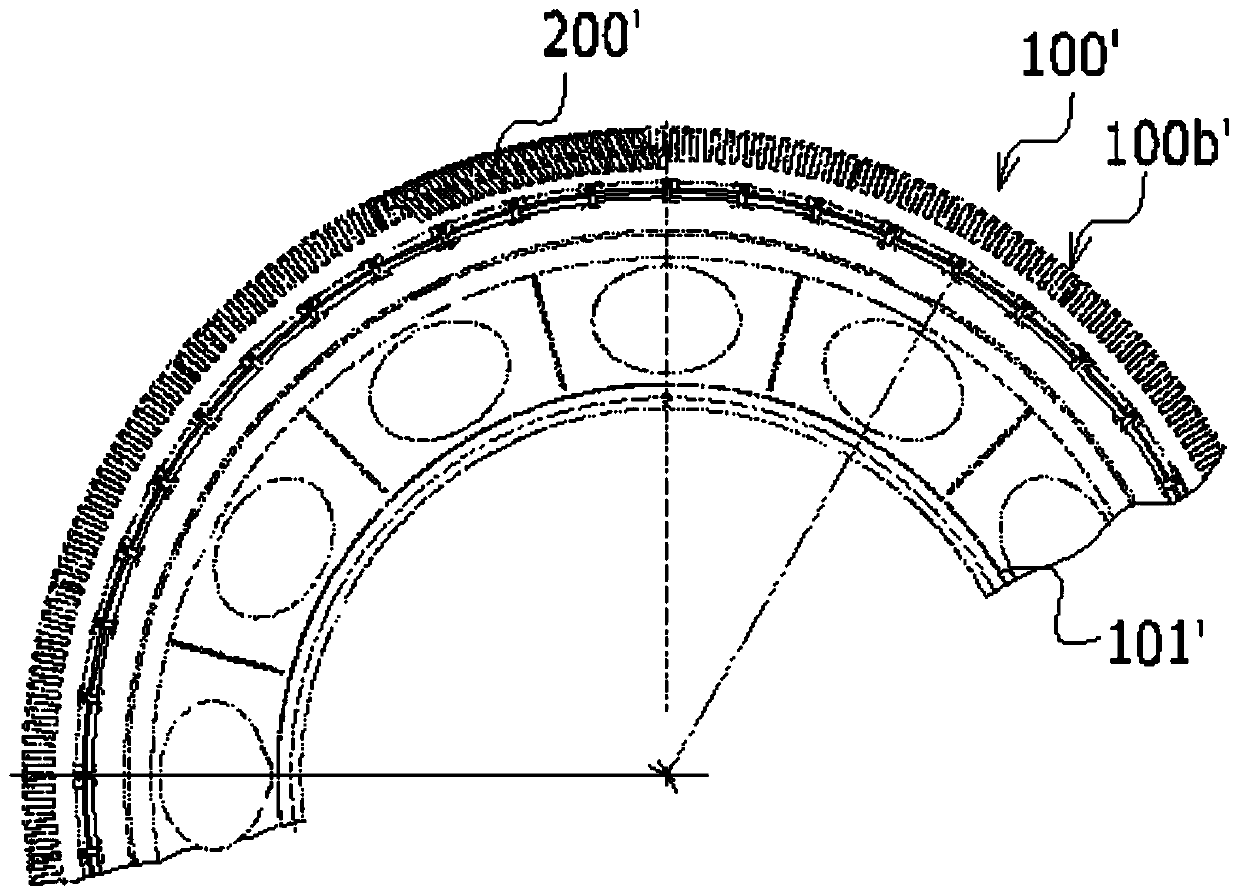

[0171] Please refer to Figure 14 , Figure 14 It is a structural schematic diagram of a specific embodiment of the armature baking device provided by the present invention.

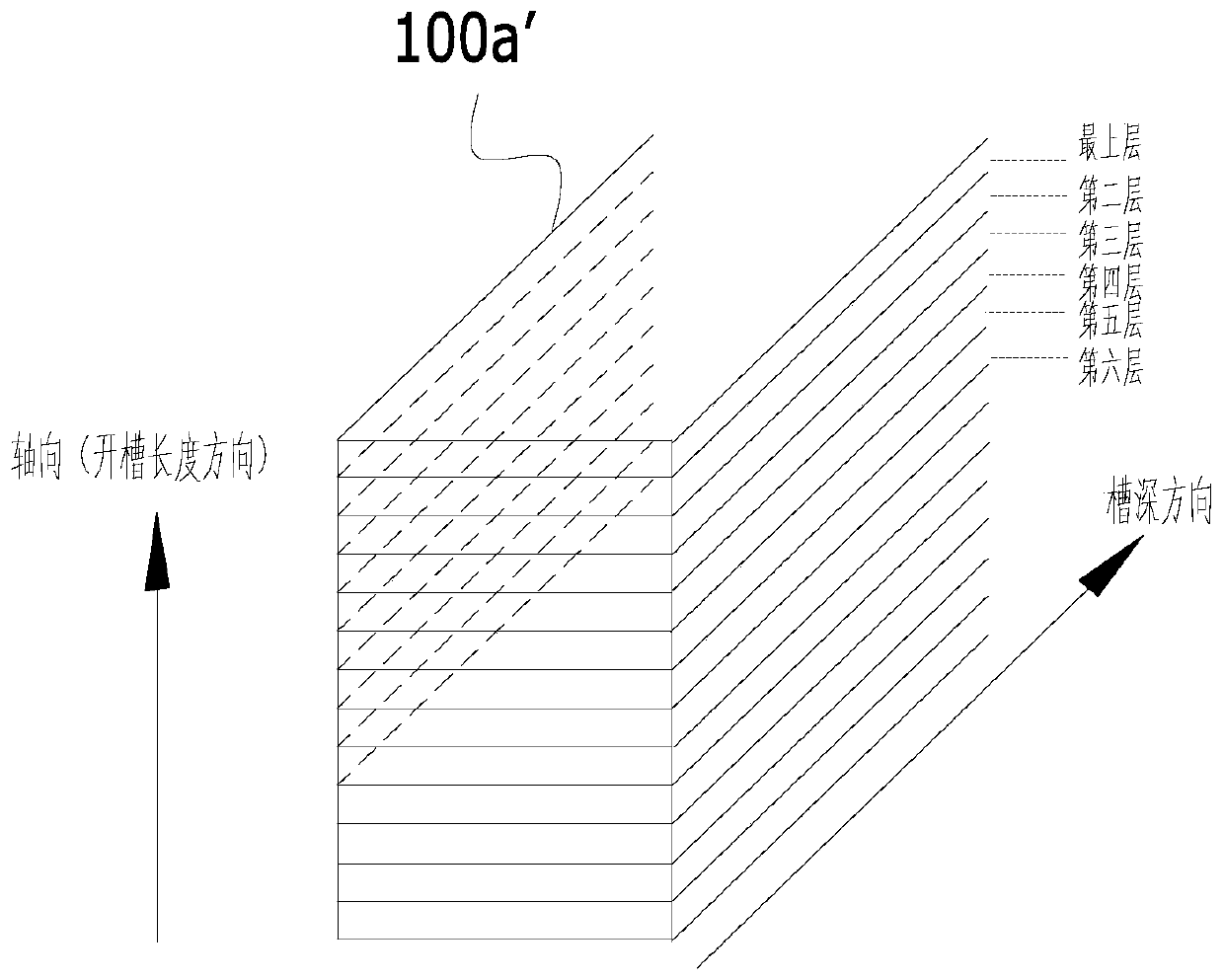

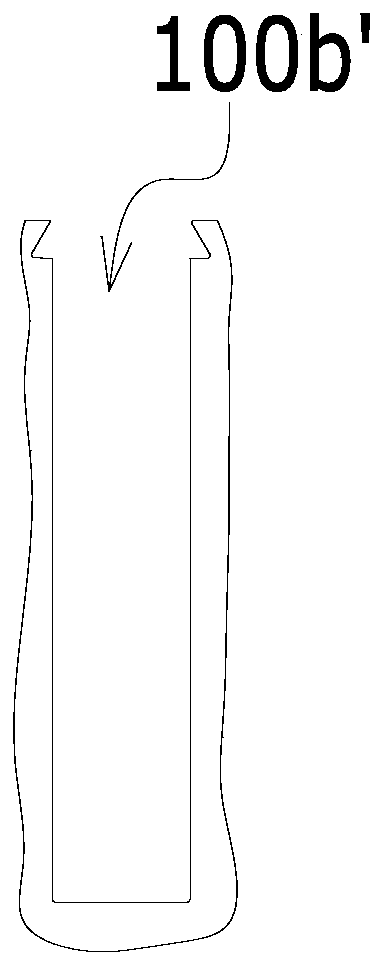

[0172] The armature of the motor, including ferromagnetic components (or magnetic permeable components) and windings 200 (ie, coils), such as Figure 14 As shown, the ferromagnetic component 100, also known as the iron core, can be formed by stacking several ferromagnetic laminations 100a in the axial direction. The ferromagnetic laminations 100a can be, for example, silicon steel sheets or ferrite sheets. The ferromagnetic component 100 The structure and the winding manner of the winding 200 can be understood specifically with reference to the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com