Feed center discs in pulp or fiber refiners

A refiner and fiber technology, applied in pulp beating/refining methods, fiber raw materials, fiber raw material processing, etc., can solve problems such as the influence of pulp/fiber distribution, achieve uniform fiber quality, less feed change, and low energy The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention relates generally to refining of lignocellulose-containing material and more particularly to center disks for rotors in pulp or fiber refiners and pulp or fiber refiners having rotors comprising such center disks.

[0030] Throughout the figures, the same reference numerals are used for similar or corresponding elements.

[0031] As mentioned in the background section, there is a continuing need in the art to further improve pulp / fiber distribution in pulp / fiber refiners. Therefore, there is still a need for a feed center disc that further improves the pulp / fiber distribution in the refining zone of a pulp / fiber refiner.

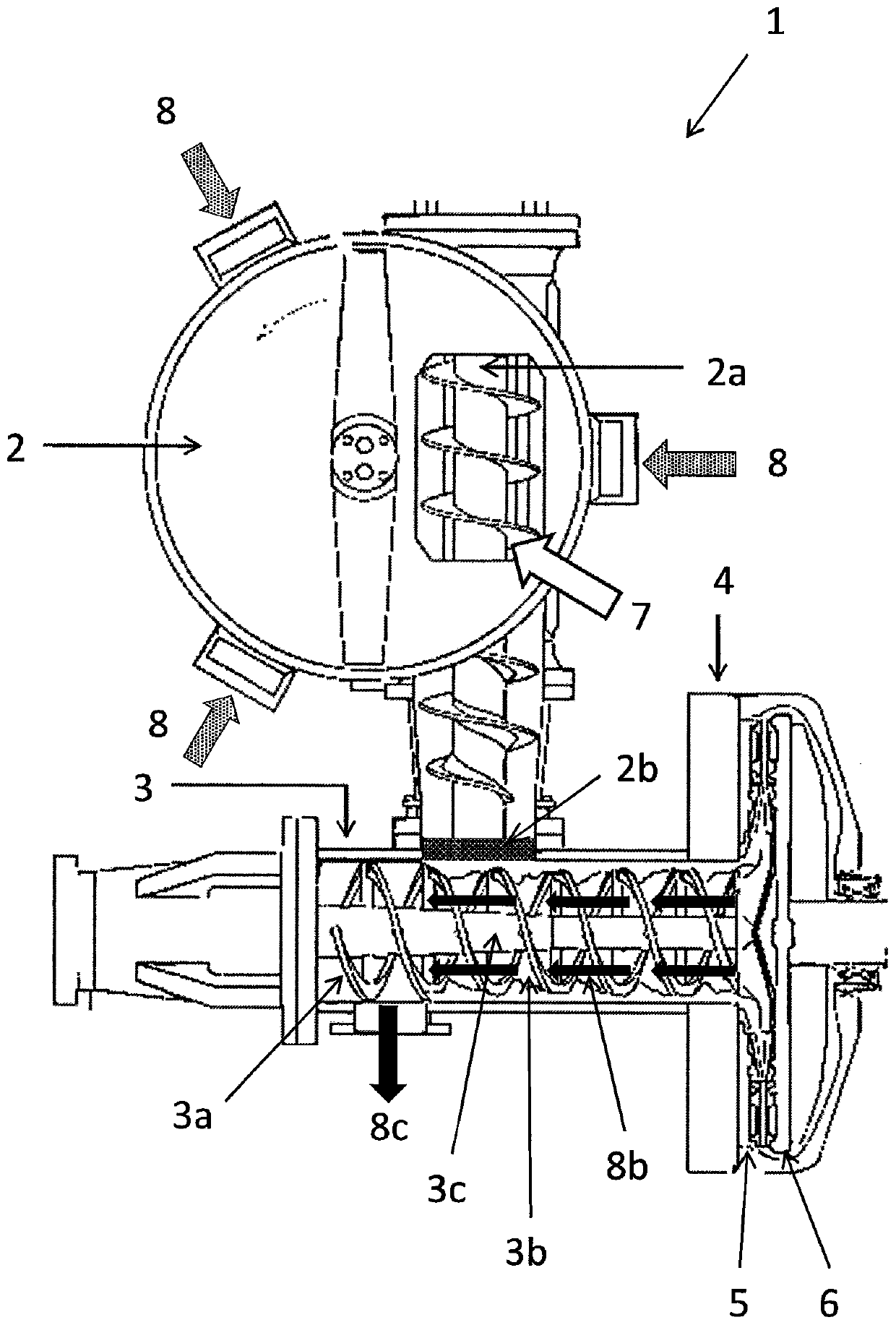

[0032] As mentioned above, figure 1 is a schematic diagram of a part of an embodiment of a pulp or fiber refiner 1 . Lignocellulose-containing material 7 such as wood chips is fed into the pre-heater 2 . Steam 8 is fed at the bottom of the preheater 2 and passed upwards through the chip pile. Chips are discharged from the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com