Chemical conversion system to replace empty containers with full ones

A container and destination technology, applied in the direction of machines/engines, liquid variable displacement machines, liquid flow control devices, etc., can solve problems such as troublesome conversion process and difficulties, and achieve the effect of reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

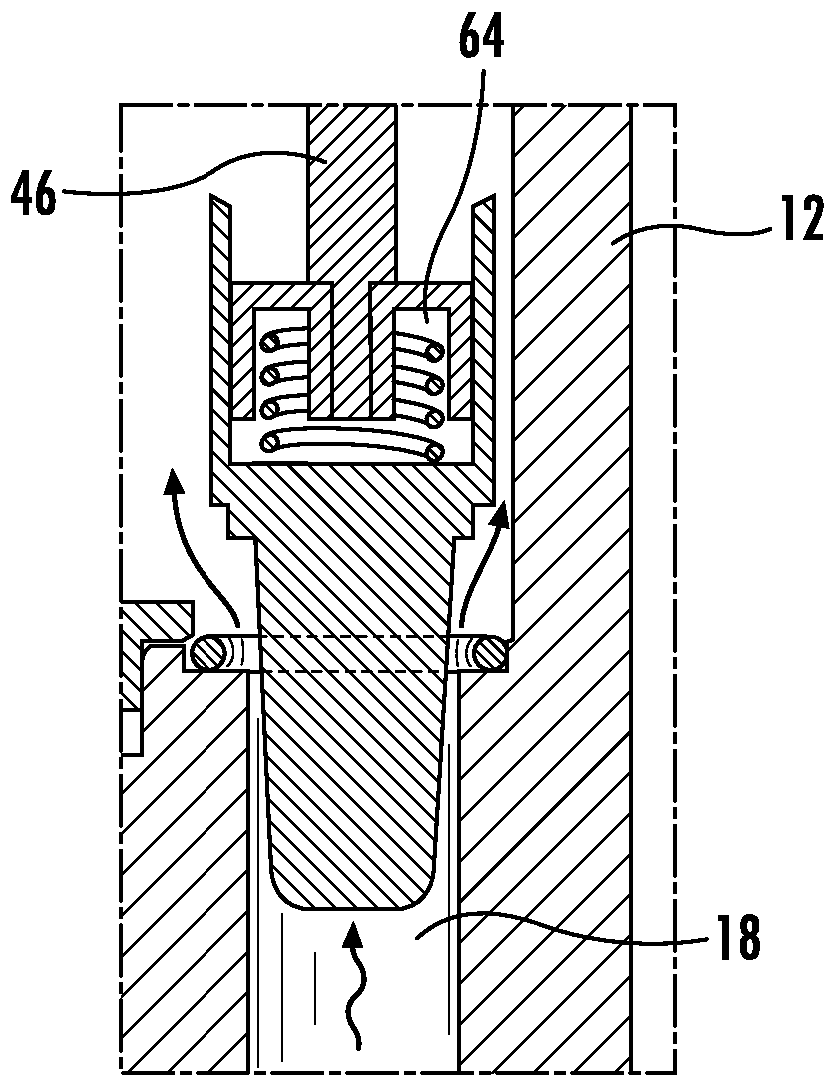

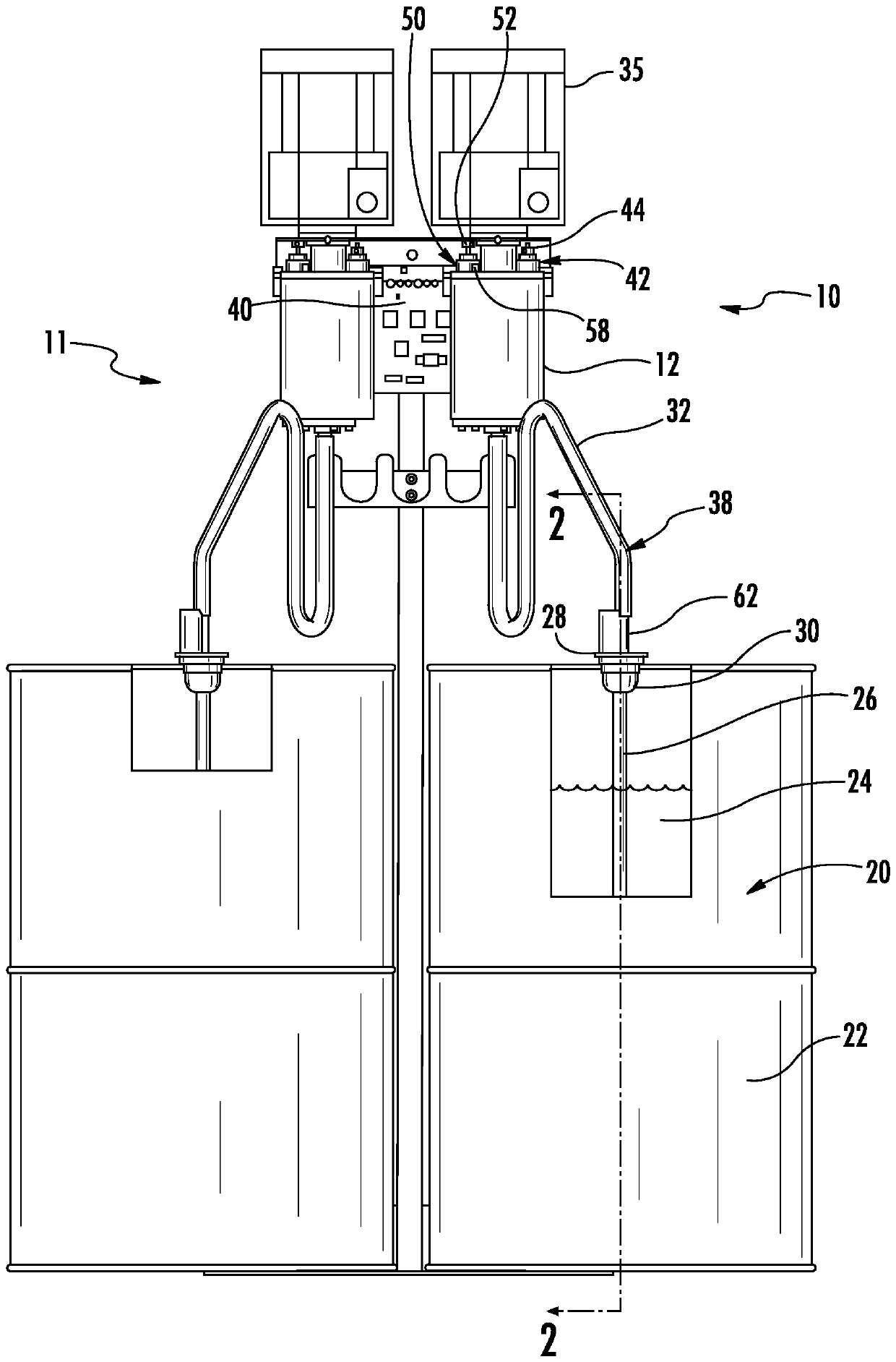

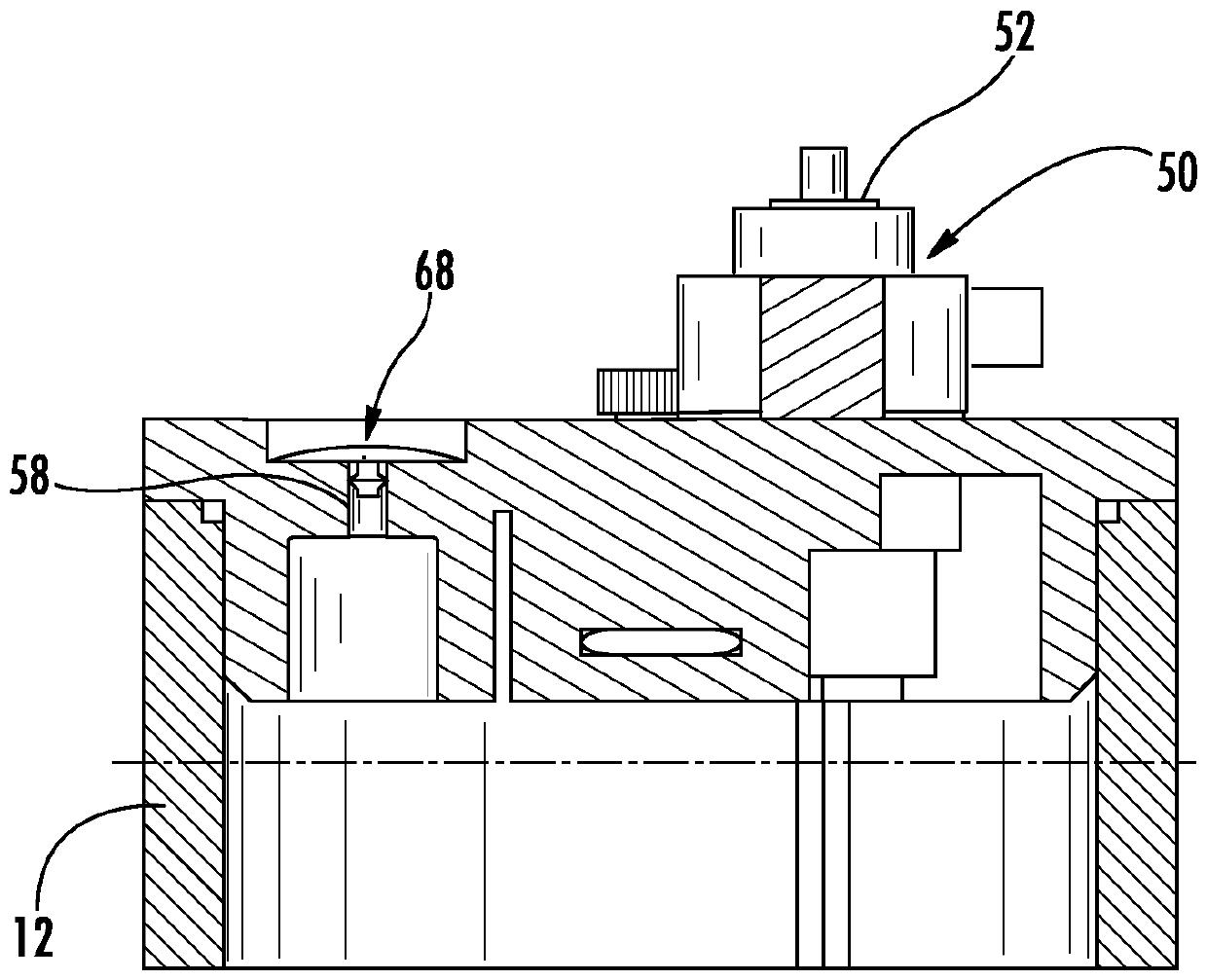

[0030] Embodiments of the disclosed subject matter relate to a system 10 ( figure 1 , 7 ), which has a storage tank 12, a pump 14 within the storage tank, a discharge path 16 connecting the pump outlet 66 to the storage tank 12, and a recirculation path 18 connecting the pump inlet 34 to the storage tank 12, as herein as described in more detail.

[0031] The system 10 operates to supply liquid from a liquid source 20 to a destination outside of the storage tank 12, such as, for example, to a dispensing valve 100 ( Figure 14 ), or to a dispenser for foam-in-bag or foam-in-place equipment (used to mix liquids to create polyurethane foam). The destination receives liquid 24 from pump outlet 66 . ( figure 1 , 7 ). although figure 1 Two supply systems are shown (ie, system 10 and system 11 ), but only system 10 is described in detail herein because system 11 is generally similar to system 10 . System 10 and system 11 may cooperate to provide two different liquids to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com