Tank with fill level indicator and compact unit with such a tank

An indicator, level sensor technology for use in the field of compact units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

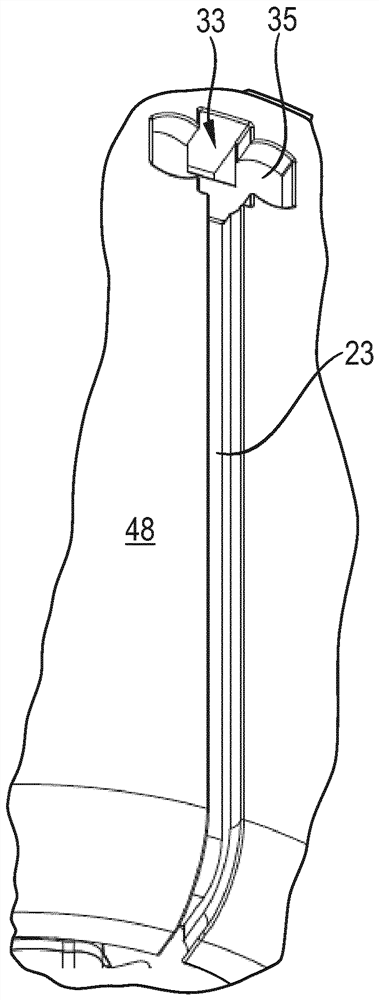

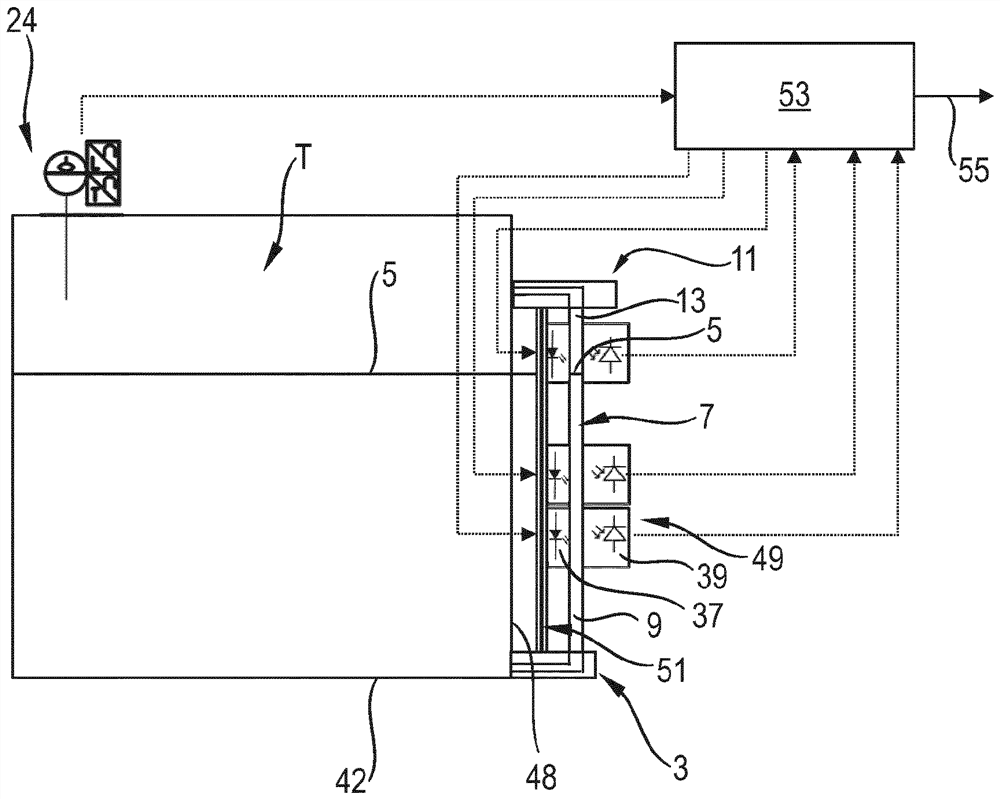

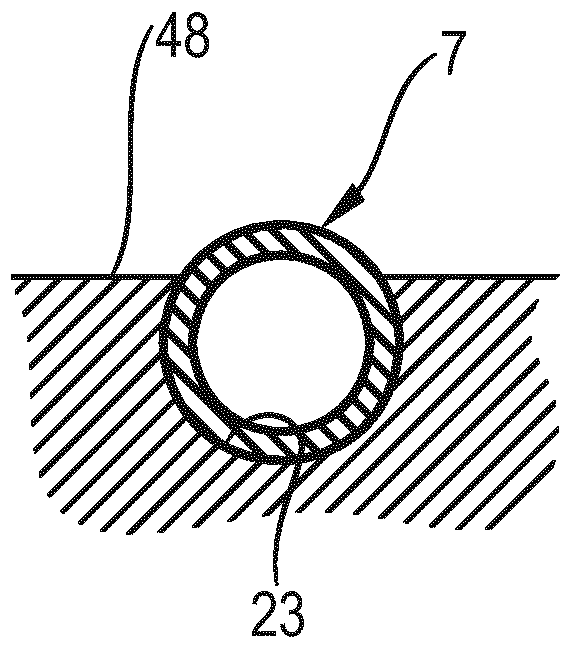

[0038] figure 1 A first exemplary embodiment of a tank T is shown in a schematic side view, in the interior of which hydraulic oil is accommodated with a fill level 5 . In the lower region of the outer wall 48 , the lower connection 3 is arranged as close as possible to the bottom 42 of the tank T. As shown in FIG. This lower connection connects the hose 7—more precisely its first end section 9—to the interior of the tank T via a bent channel. The hose 7 runs vertically and parallel to the outer wall 48 . exist figure 1 In the indicated position shown, the hose 7 has the function of a riser. The hose 7 thus serves as a visual fill level indicator which can be read from a wide angular range of approximately 180° from the outside of the tank T.

[0039]Above the filling level 5 , the upper connection 11 is arranged on the outer wall 48 of the tank T. As shown in FIG. In the indicated position of the hose 7 , the second end section 13 of the hose 7 is also connected to the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com