Oil paint blow-dry equipment for wood painting

A technology for paint and wood, which is applied in the field of paint drying equipment for wood spray painting, and can solve the problems of easy blowing of foreign matter to the surface of the paint and long waiting time for the paint to dry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

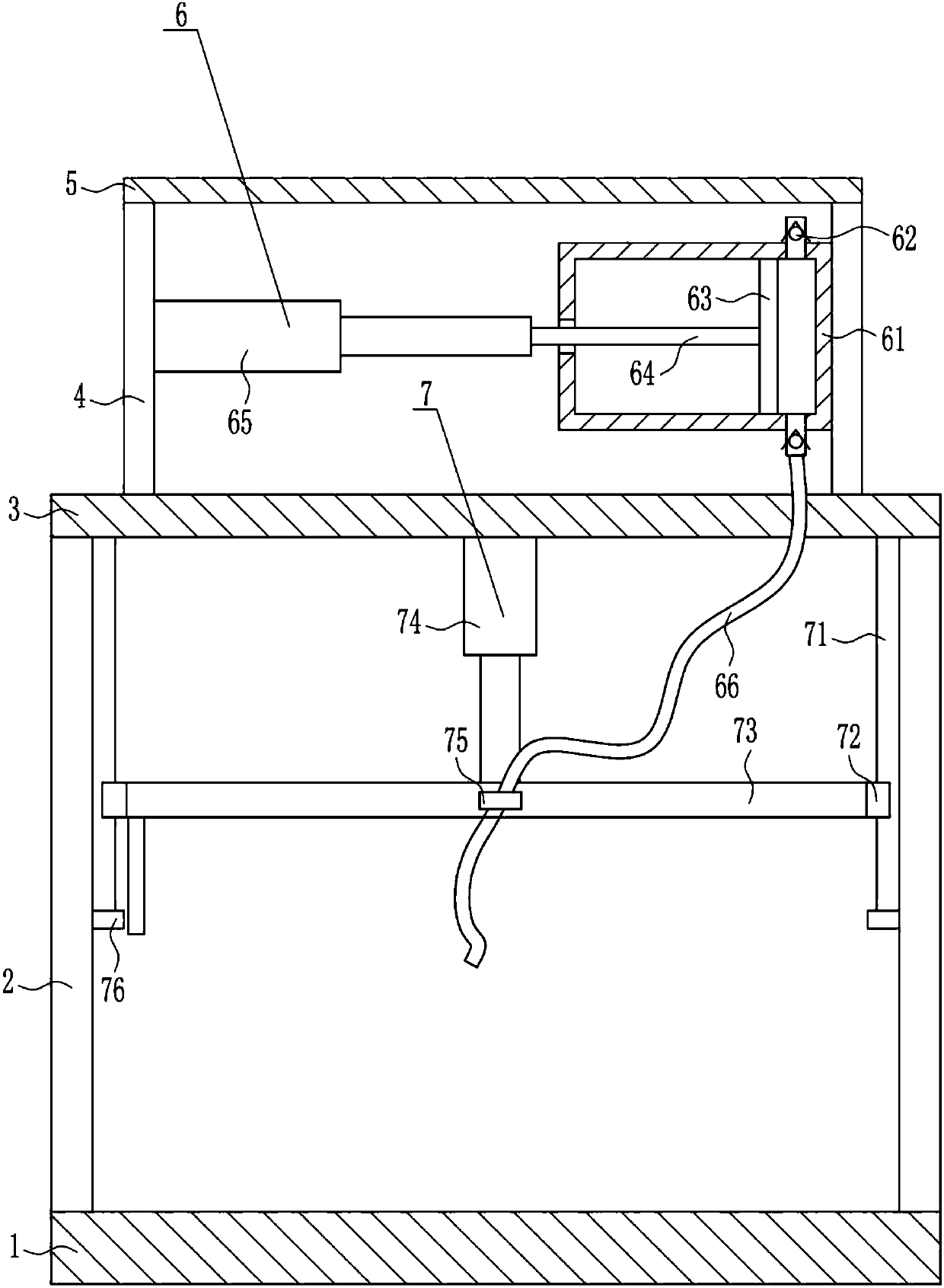

[0031] A kind of paint drying equipment for wood spray painting, such as Figure 1-5 As shown, it includes a bottom plate 1, a support plate 2, a top plate 3, a bracket 4, a horizontal plate 5, an air blowing device 6 and a lifting device 7, and the top of the bottom plate 1 is symmetrically installed vertically with a support plate 2, and the top of the two support plates 2 A top plate 3 is installed, and a support 4 is installed symmetrically on the top of the top plate 3. A horizontal plate 5 is installed on the top of the two supports 4. An air blowing device 6 is provided between the two supports 4. A lifting device 7 is provided between the two support plates 2. The blowing part of the blowing device 6 is located on the lifting part of the lifting device 7 .

Embodiment 2

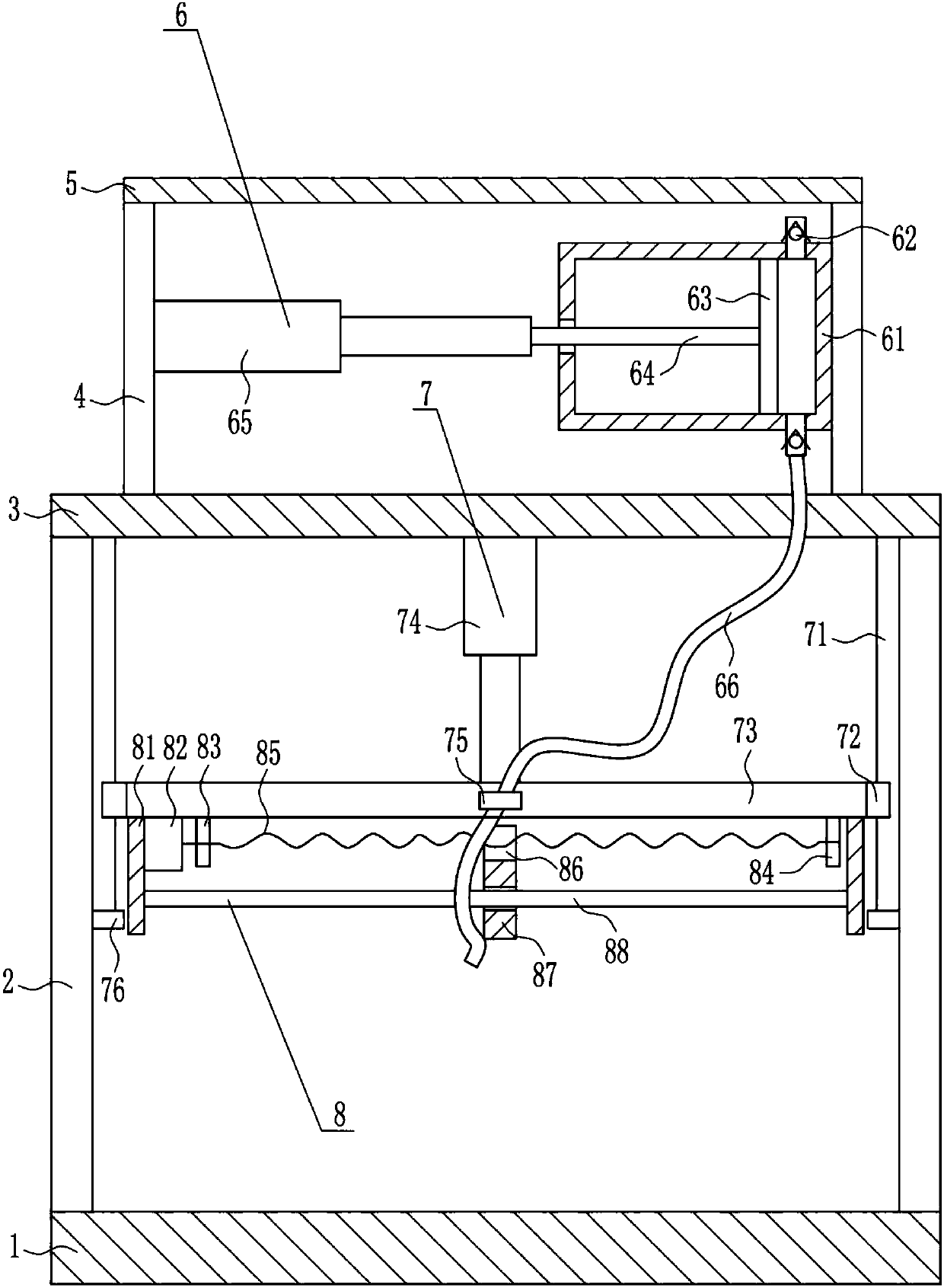

[0033] A kind of paint drying equipment for wood spray painting, such as Figure 1-5 As shown, it includes a bottom plate 1, a support plate 2, a top plate 3, a bracket 4, a horizontal plate 5, an air blowing device 6 and a lifting device 7, and the top of the bottom plate 1 is symmetrically installed vertically with a support plate 2, and the top of the two support plates 2 A top plate 3 is installed, and a support 4 is installed symmetrically on the top of the top plate 3. A horizontal plate 5 is installed on the top of the two supports 4. An air blowing device 6 is provided between the two supports 4. A lifting device 7 is provided between the two support plates 2. The blowing part of the blowing device 6 is located on the lifting part of the lifting device 7 .

[0034] Blowing device 6 comprises compression cylinder 61, one-way valve 62, piston 63, movable rod 64, first air cylinder 65 and air outlet pipe 66, and compression cylinder 61 is installed on the left side of rig...

Embodiment 3

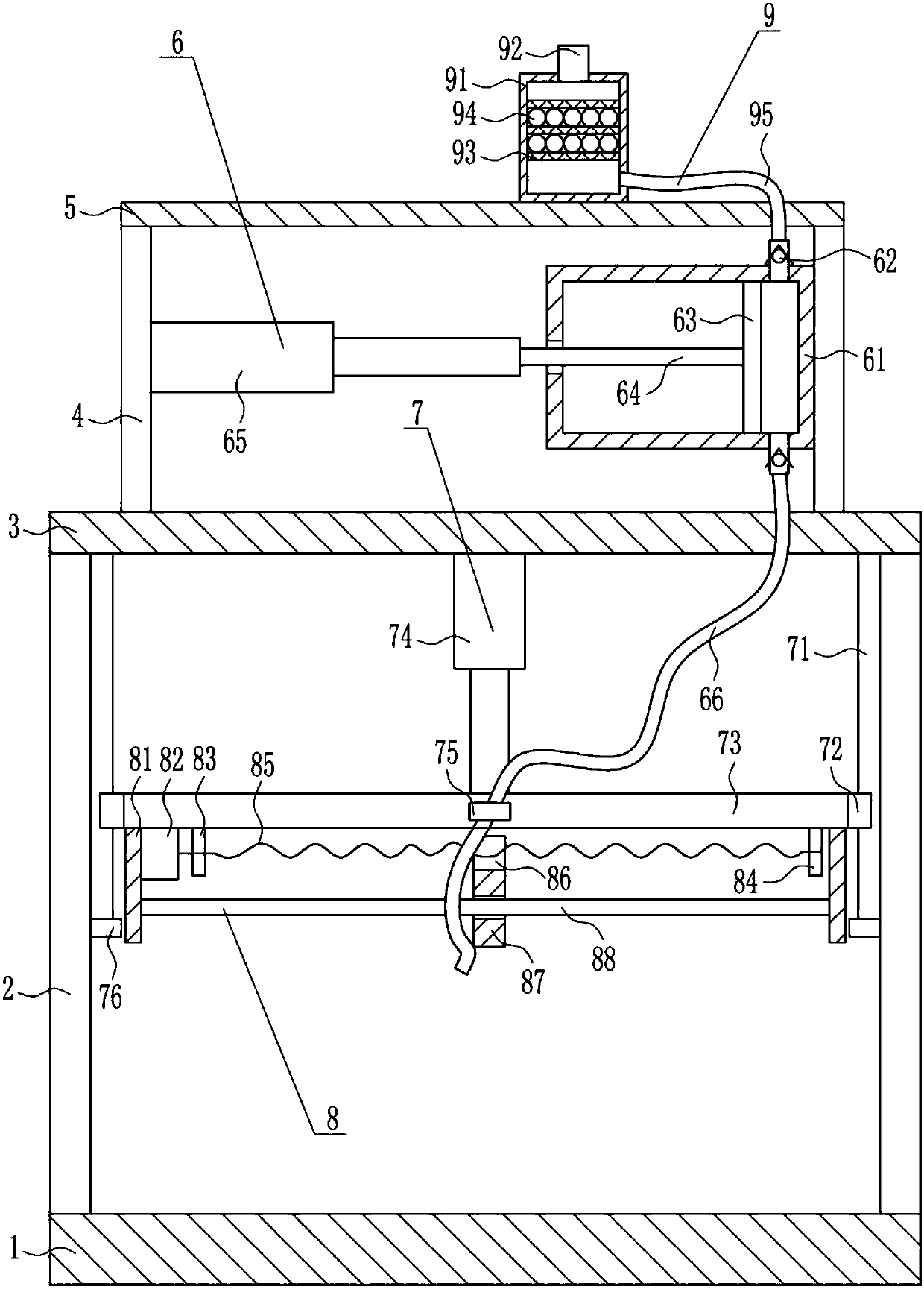

[0036] A kind of paint drying equipment for wood spray painting, such as Figure 1-5 As shown, it includes a bottom plate 1, a support plate 2, a top plate 3, a bracket 4, a horizontal plate 5, an air blowing device 6 and a lifting device 7, and the top of the bottom plate 1 is symmetrically installed vertically with a support plate 2, and the top of the two support plates 2 A top plate 3 is installed, and a support 4 is installed symmetrically on the top of the top plate 3. A horizontal plate 5 is installed on the top of the two supports 4. An air blowing device 6 is provided between the two supports 4. A lifting device 7 is provided between the two support plates 2. The blowing part of the blowing device 6 is located on the lifting part of the lifting device 7 .

[0037] Blowing device 6 comprises compression cylinder 61, one-way valve 62, piston 63, movable rod 64, first air cylinder 65 and air outlet pipe 66, and compression cylinder 61 is installed on the left side of rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com