Spraying device for glass production

A technology of spraying device and glass, which is applied in the direction of spraying device, spraying device, cleaning method using liquid, etc., which can solve the problems of cleaning section pollution, poor blowdown capacity of spray hole, small flow rate, etc., to increase the washing area and improve cleaning Effect, avoid the effect of cleaning dead corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

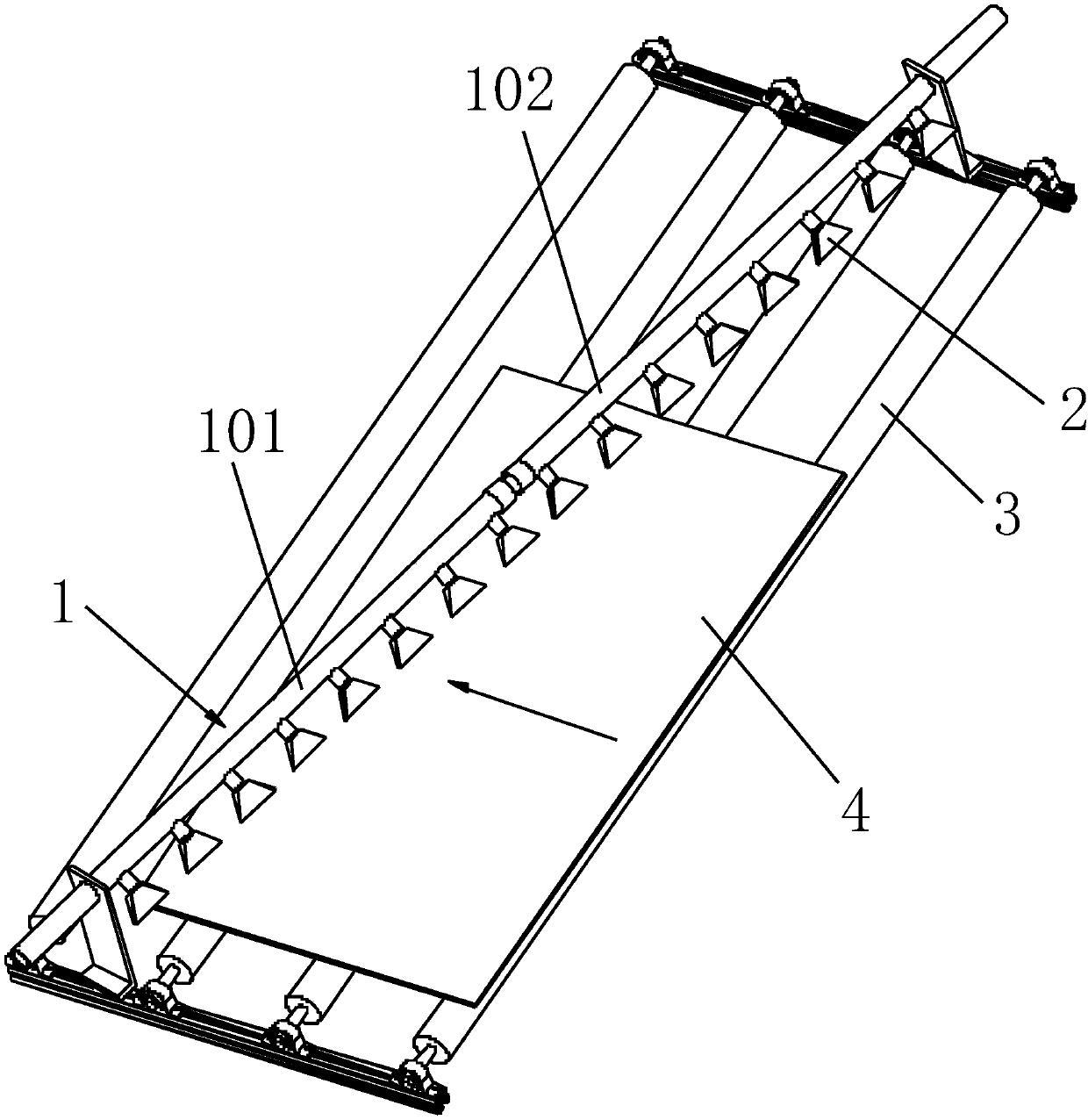

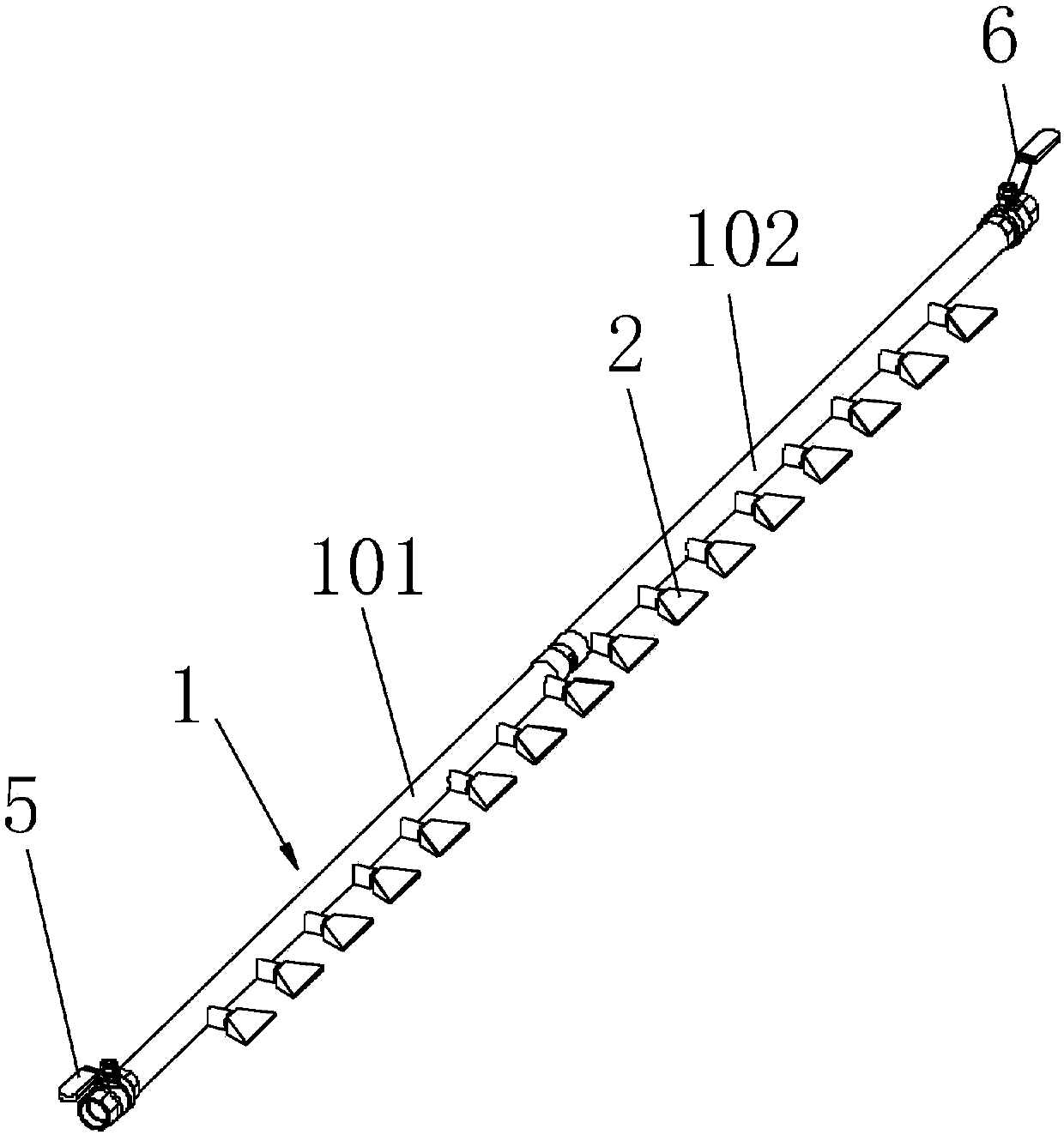

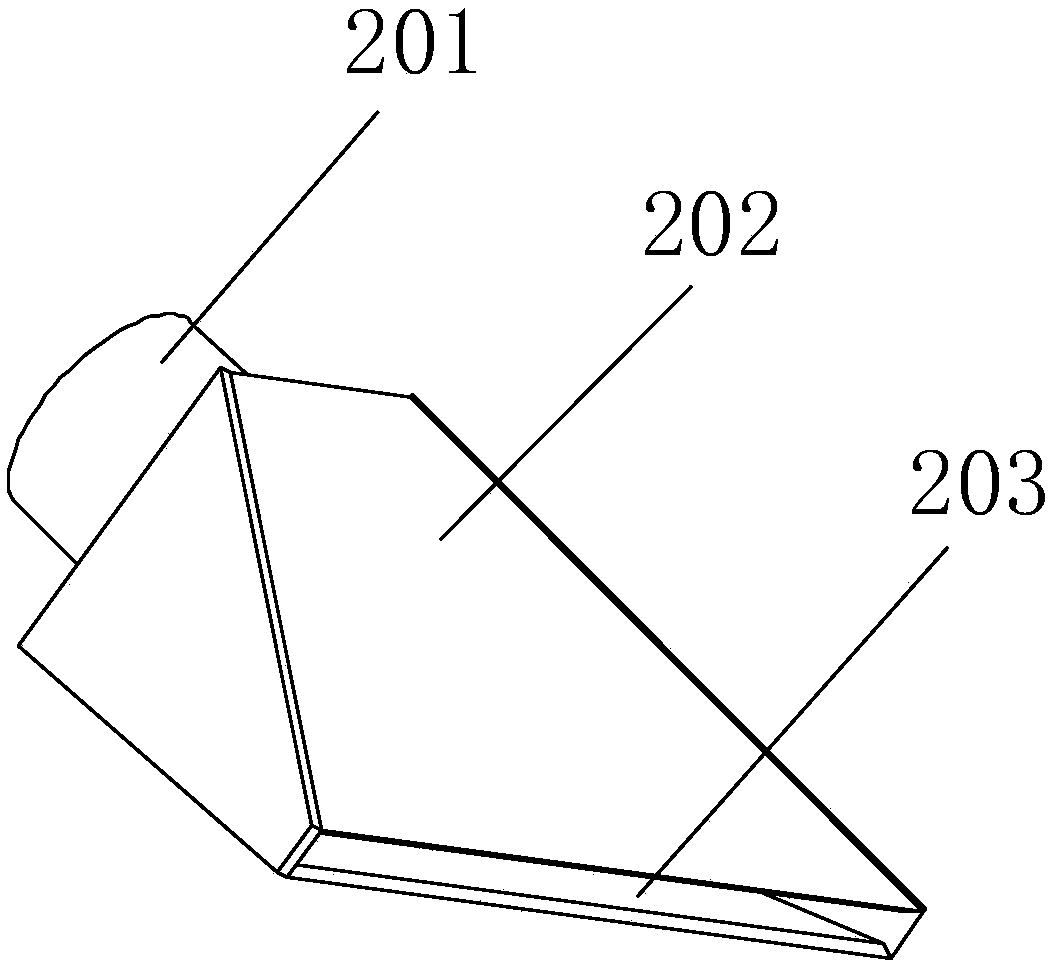

[0027] Such as Figure 1 to Figure 5 As shown, a spraying device used in glass production, wherein the glass 4 is laid flat on the transmission mechanism and transported from one end to the other end of the transmission mechanism, the spraying device at least includes a hollow glass that is erected directly above the glass 4 and has a hollow interior. The spray pipe 1 is detachably provided with a plurality of nozzles 2, all the nozzles 2 are arranged at intervals along the axial direction of the spray pipe 1, the water inlet end of the nozzle 2 communicates with the inside of the spray pipe 1, and the nozzles 2 The water outlet end is a flat strip water outlet 203, and the axis direction of the nozzle 1 is at an angle of 50°-80° to the transmission direction of the glass 4.

[0028] Preferably, the axial direction of the nozzle 1 is at an angle of 75°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com