Automatic flywheel deburring device

A technology of deburring and deburring mechanism, which is applied in the field of mechanical devices, can solve the problems of high labor intensity, low efficiency, and inability to deburr the keyway of the flywheel, etc., and achieve the effect of reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

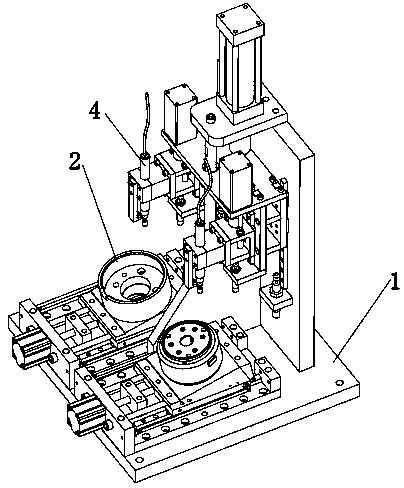

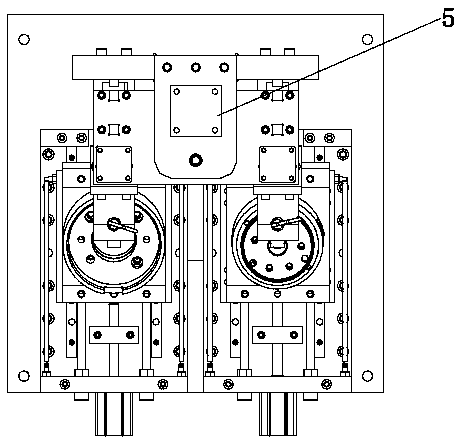

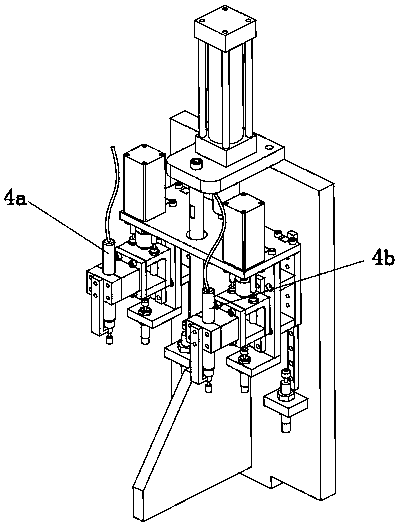

[0028] refer to Figure 1 to Figure 9 A flywheel automatic deburring device shown includes a supporting plate 1, a jig mechanism 2, a material shifting mechanism 3 for driving the jig mechanism 2 to move in a horizontal direction, a deburring mechanism 4 and a lifting mechanism 5. Both the material shifting mechanism 3 and the lifting mechanism 5 are located at the top of the supporting plate 1, the jig mechanism 2 is located at the top of the material moving mechanism 3, and the lifting mechanism 5 includes a fixed plate 5a located at the top of the supporting plate 1 and fixed on the The mounting plate 5b on the top of the fixed plate 5a is provided with a horizontally arranged slide plate 5c just below the mounting plate 5b, and the top of the mounting plate 5b is provided with a lift cylinder 5d for driving the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap