Quantitative fodder packaging equipment for pig fodder production

A technology for pig feed and feed, which is applied in packaging, solid materials, transportation and packaging, etc., can solve the problems of large error and inconvenient packaging, and achieve the effect of small error, convenient packaging and speeding up feeding speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

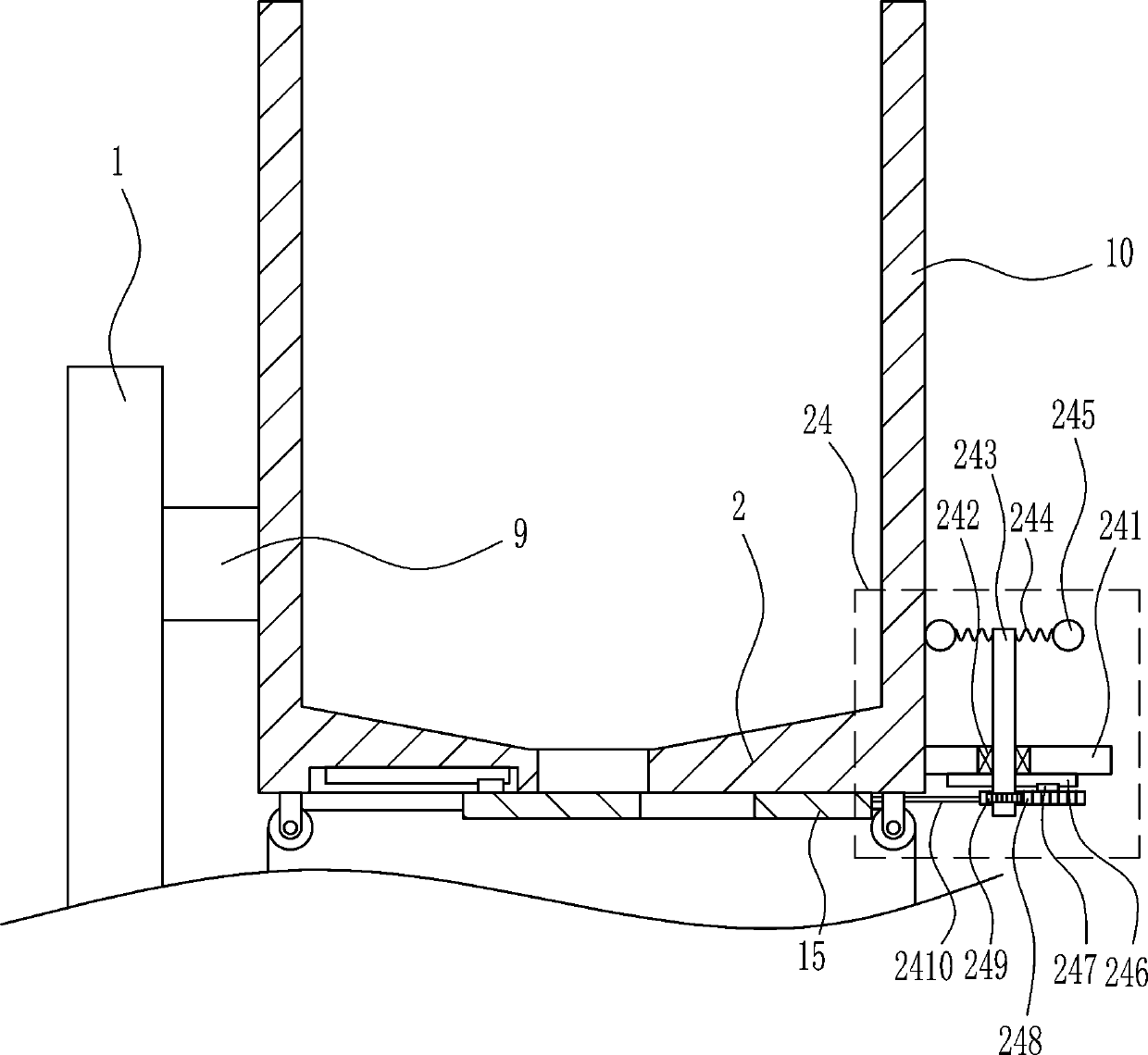

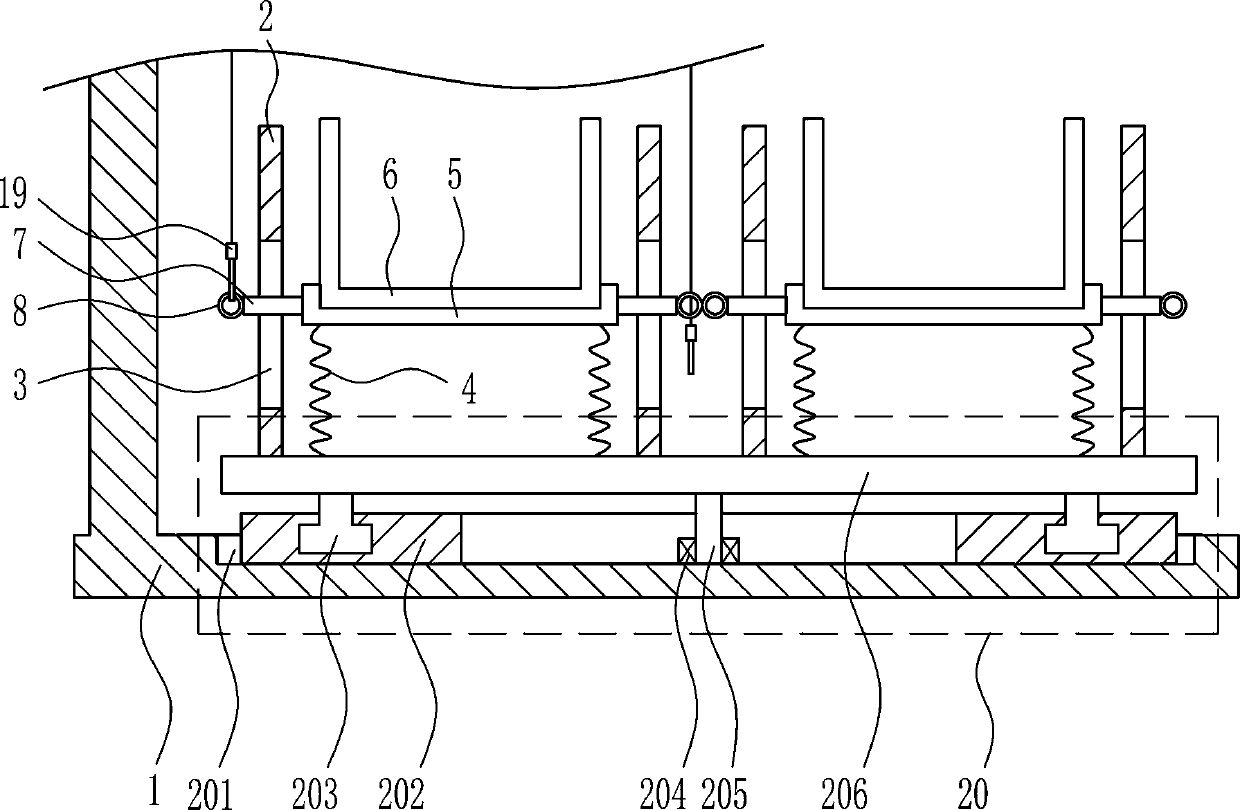

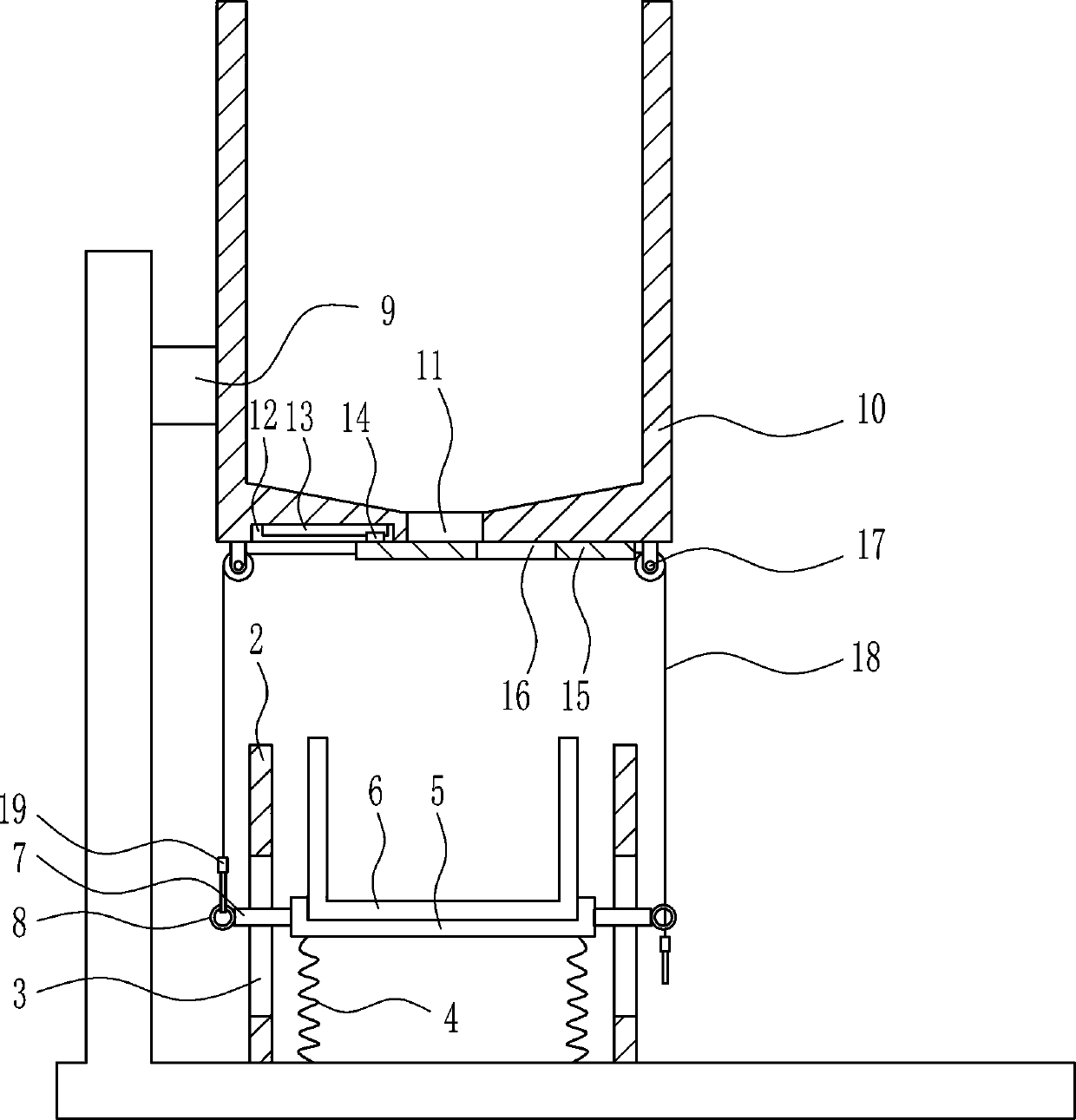

[0027] A feed quantitative packaging equipment for pig feed production, such as Figure 1-5 As shown, it includes a mounting frame 1, a guide plate 2, a first spring 4, a placement frame 5, a first frame body 6, a guide rod 7, a hanging ring 8, a pole 9, a second frame body 10, and a first slide rail 13. The first slider 14, the baffle plate 15, the fixed pulley 17, the pull wire 18 and the hook 19, the left and right sides of the inner bottom of the installation frame 1 are symmetrically provided with a guide plate 2, and the lower part of the guide plate 2 is provided with a guide hole 3, and the guide plate The left and right sides of the mounting frame 1 between the 2 are symmetrically provided with a first spring 4, the top of the first spring 4 is connected with a placement frame 5, and a first frame body 6 is placed in the placement frame 5, and the left and right sides of the placement frame 5 are arranged A guide rod 7 is provided, the guide rod 7 passes through the g...

Embodiment 2

[0029] A feed quantitative packaging equipment for pig feed production, such as Figure 1-5 As shown, it includes a mounting frame 1, a guide plate 2, a first spring 4, a placement frame 5, a first frame body 6, a guide rod 7, a hanging ring 8, a pole 9, a second frame body 10, and a first slide rail 13. The first slider 14, the baffle plate 15, the fixed pulley 17, the pull wire 18 and the hook 19, the left and right sides of the inner bottom of the installation frame 1 are symmetrically provided with a guide plate 2, and the lower part of the guide plate 2 is provided with a guide hole 3, and the guide plate The left and right sides of the mounting frame 1 between the 2 are symmetrically provided with a first spring 4, the top of the first spring 4 is connected with a placement frame 5, and a first frame body 6 is placed in the placement frame 5, and the left and right sides of the placement frame 5 are arranged A guide rod 7 is provided, the guide rod 7 passes through the g...

Embodiment 3

[0032] A feed quantitative packaging equipment for pig feed production, such as Figure 1-5 As shown, it includes a mounting frame 1, a guide plate 2, a first spring 4, a placement frame 5, a first frame body 6, a guide rod 7, a hanging ring 8, a pole 9, a second frame body 10, and a first slide rail 13. The first slider 14, the baffle plate 15, the fixed pulley 17, the pull wire 18 and the hook 19, the left and right sides of the inner bottom of the installation frame 1 are symmetrically provided with a guide plate 2, and the lower part of the guide plate 2 is provided with a guide hole 3, and the guide plate The left and right sides of the mounting frame 1 between the 2 are symmetrically provided with a first spring 4, the top of the first spring 4 is connected with a placement frame 5, and a first frame body 6 is placed in the placement frame 5, and the left and right sides of the placement frame 5 are arranged A guide rod 7 is provided, the guide rod 7 passes through the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com