Bag stack conveying device and packaging machine

A technology of conveying device and bag bin, which is applied in the field of bag pile conveying device and packaging machine, which can solve the problems of large occupied space, unfavorable factory space setting and arrangement, and large occupied space of packaging machine, so as to save occupied space, Ensuring productivity and high versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

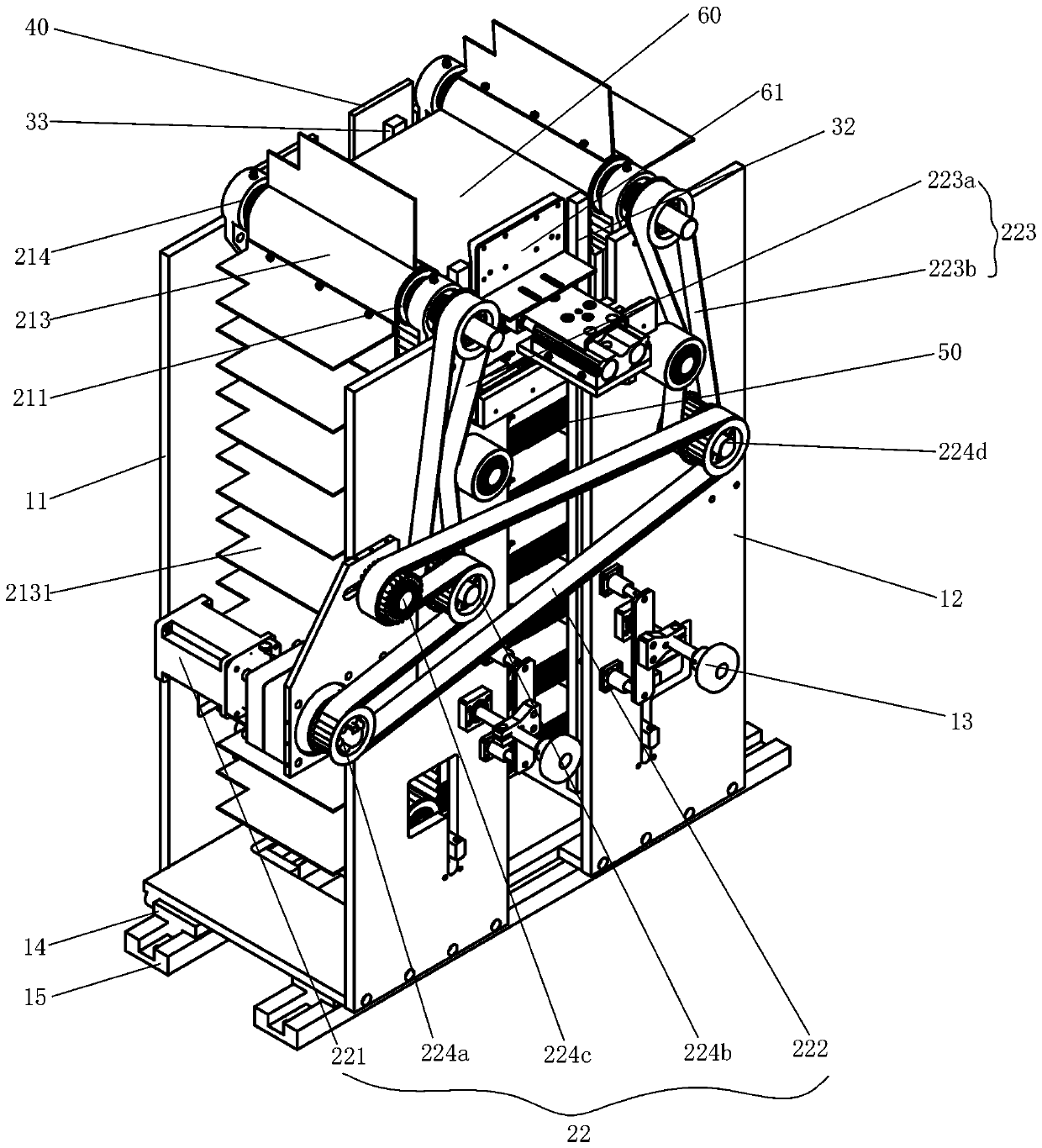

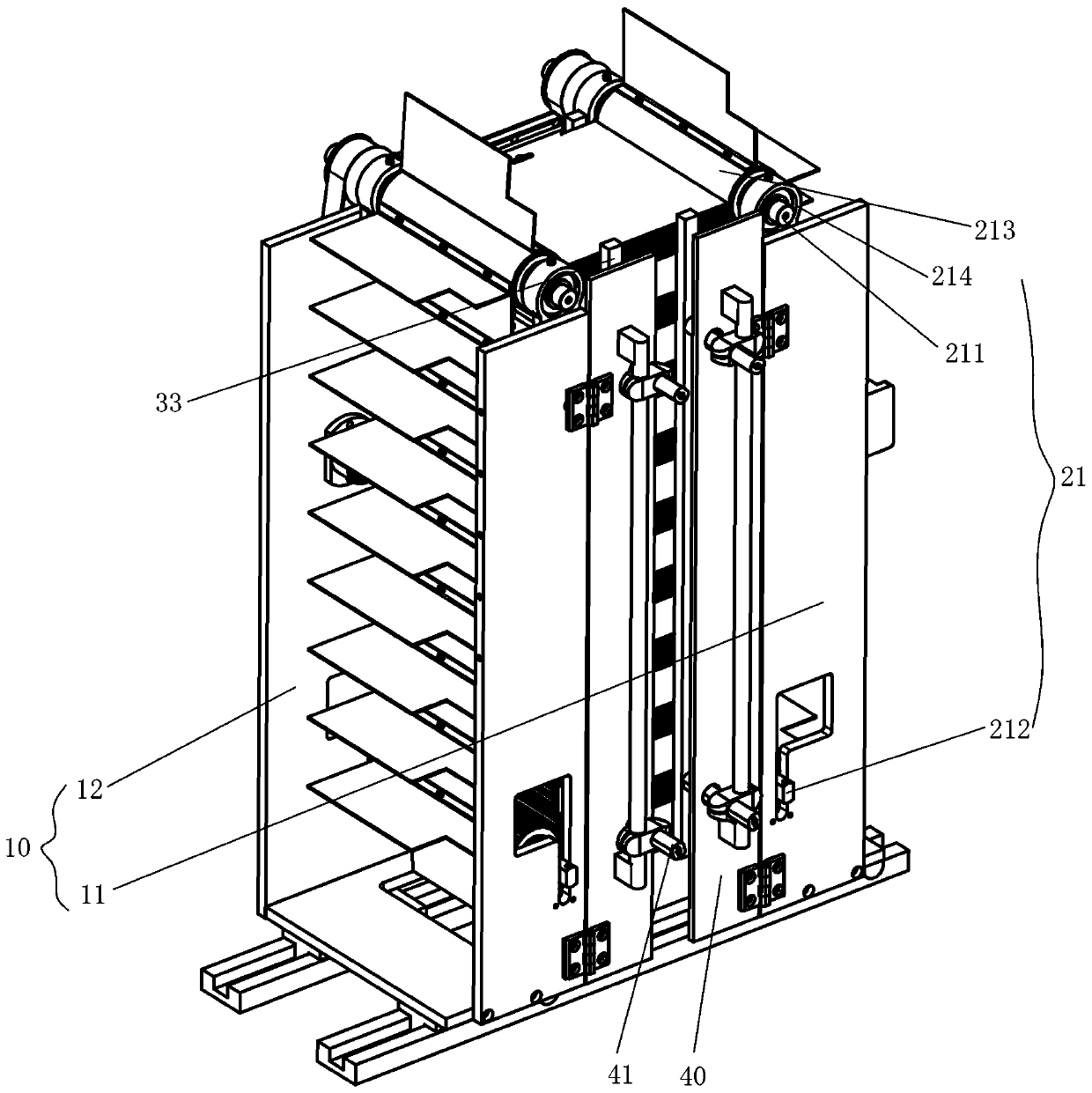

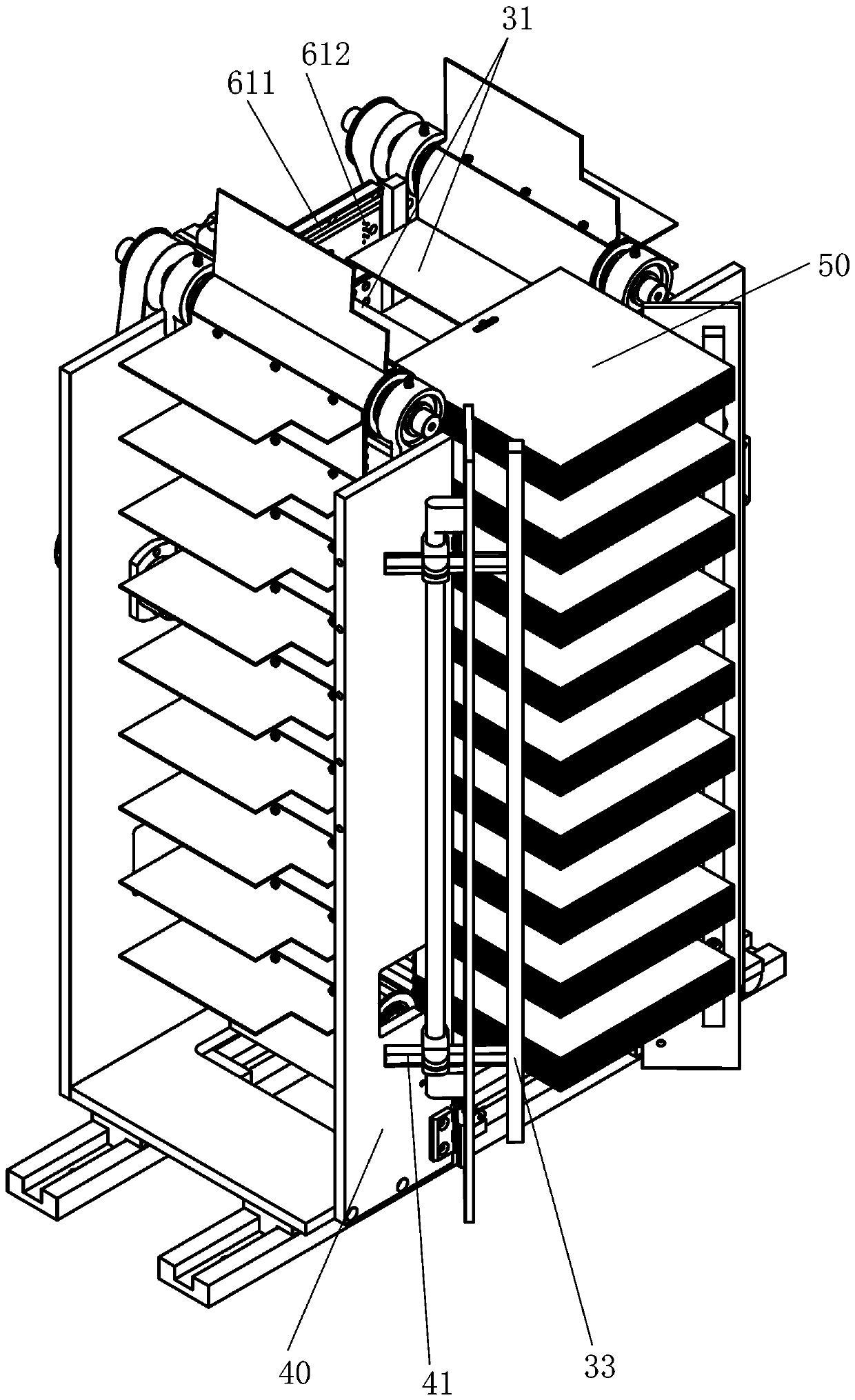

[0023] A bag stack conveying device includes a support 10 , a plurality of bag bins for placing bag stacks 50 , and a driving mechanism for driving each bag bin to move circularly to a bag picking position 60 . A plurality of bag bins are aligned on the same vertical plane.

[0024] Such as figure 1 and figure 2 As shown, the support 10 includes a left support 11 and a right support 12 arranged symmetrically.

[0025] The drive mechanism includes two pulley assemblies mounted on the two supports 10 one by one and a rotary drive 30 connecting the two pulley assemblies. The structure and principle of the two pulley assemblies are consistent, and the structure of the left pulley assembly 21 is described in detail here. The left pulley assembly 21 includes a driving pulley roller 211, a driven pulley roller 212 and a conveyor belt 213. The two ends of the driving pulley roller 211 pass through two Bearing 214 is fixed on the upper end of left bearing 11, and driven wheel rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com