Anti-dust worm-gear lifting machine with self-control stroke

A worm gear and elevator technology, applied in the elevator field, can solve the problems of inaccurate control of the lifting position, low transmission accuracy, affecting the worm gear and worm transmission, etc., and achieves the effects of good performance, high degree of control, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Further description will be made below in conjunction with the accompanying drawings.

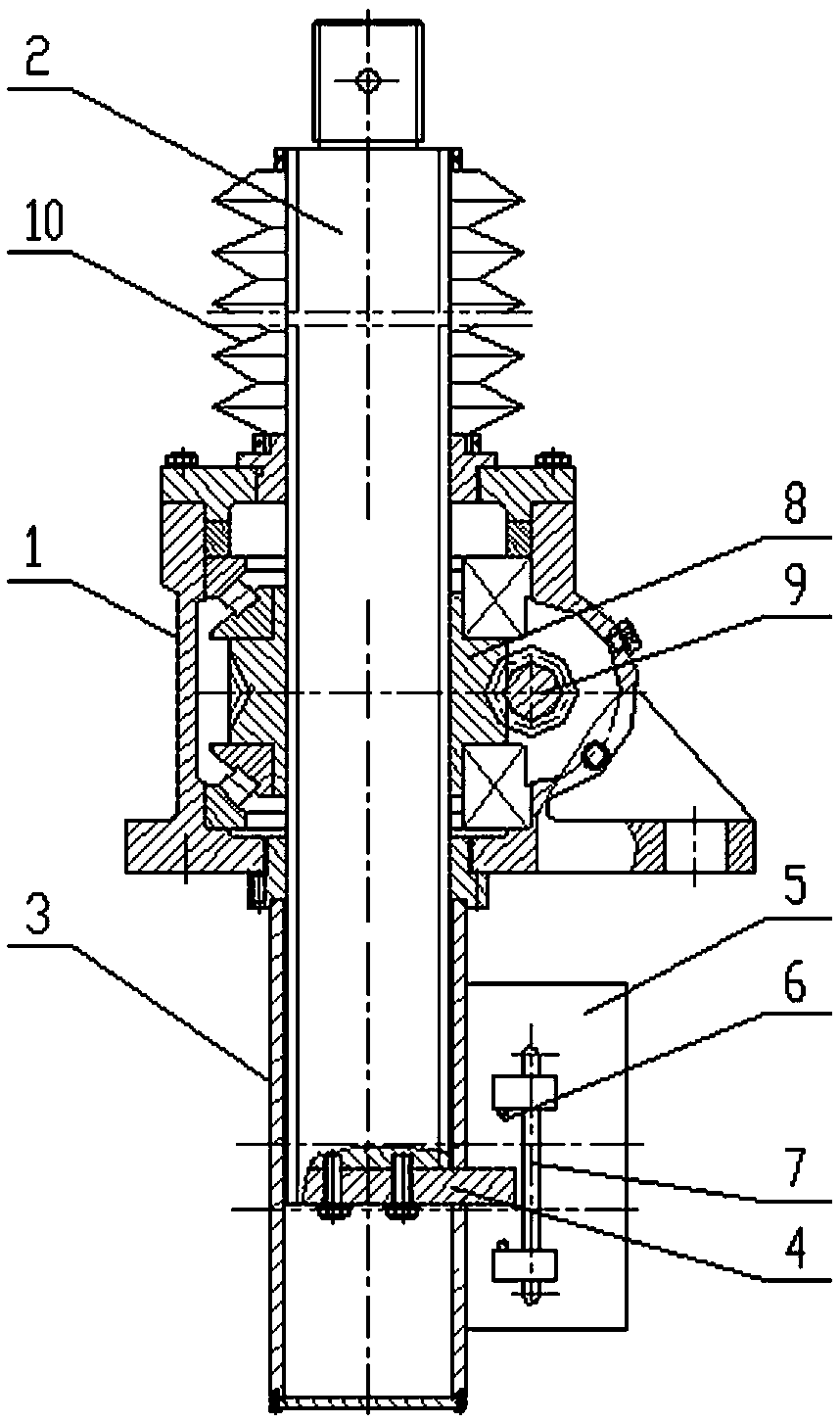

[0010] figure 1 As shown: a dust-proof stroke self-control worm gear elevator includes a box body 1, a lifting screw rod 2, a limit lifting box body 3, an anti-rotation slider 4, a limit mounting plate 5, a travel switch 6, a displacement sensor 7, a drive Worm wheel 8, driving worm 9, telescoping sleeve 10. Lifting screw mandrel 2 is pierced and connected on the casing 1 up and down, and the lifting screw mandrel extends downwards and is connected in the limit lift box 3 body below the box body and its bottom connects anti-rotation slide block 4, and the limit lift box 3 body outsides are arranged. The limit mounting plate 5 is provided with upper and lower travel switches 6 and displacement sensors 7 with adjustable relative positions up and down on the limit mounting plate, and the anti-rotation slider 4 is correspondingly arranged between the upper and lower travel switches. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com