Mounting method of sintering stock bin

An installation method and batching bin technology, applied in the direction of hoisting device, hoisting device, etc., can solve the problems of high mechanical cost, high space requirements of surrounding sites, time-consuming and labor-intensive, etc., and achieve the effect of saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

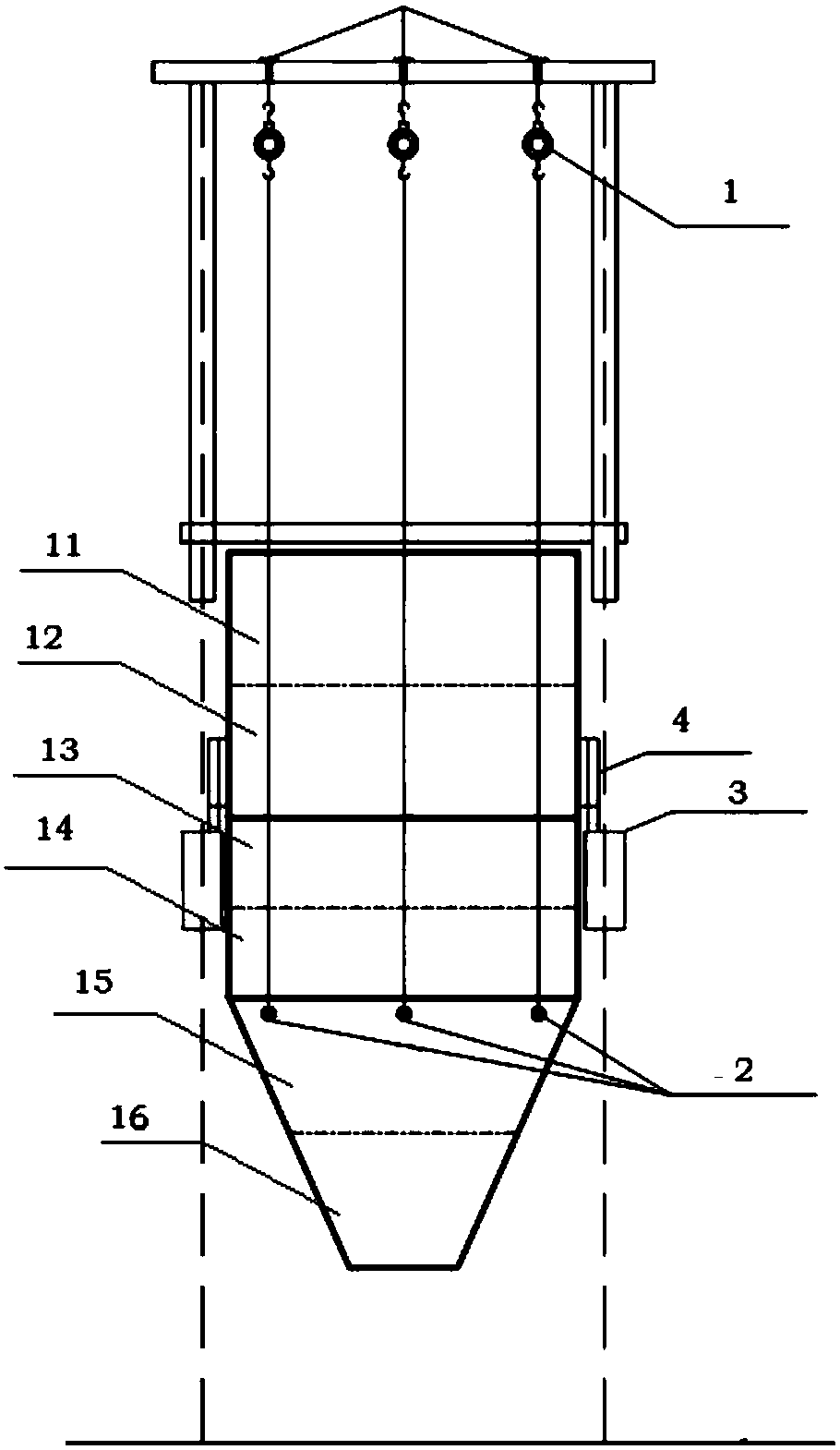

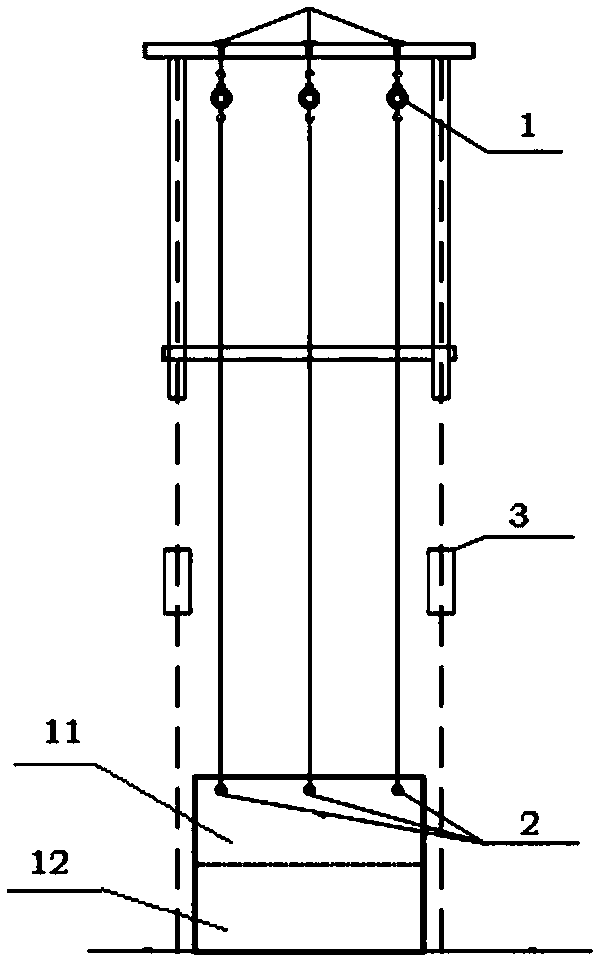

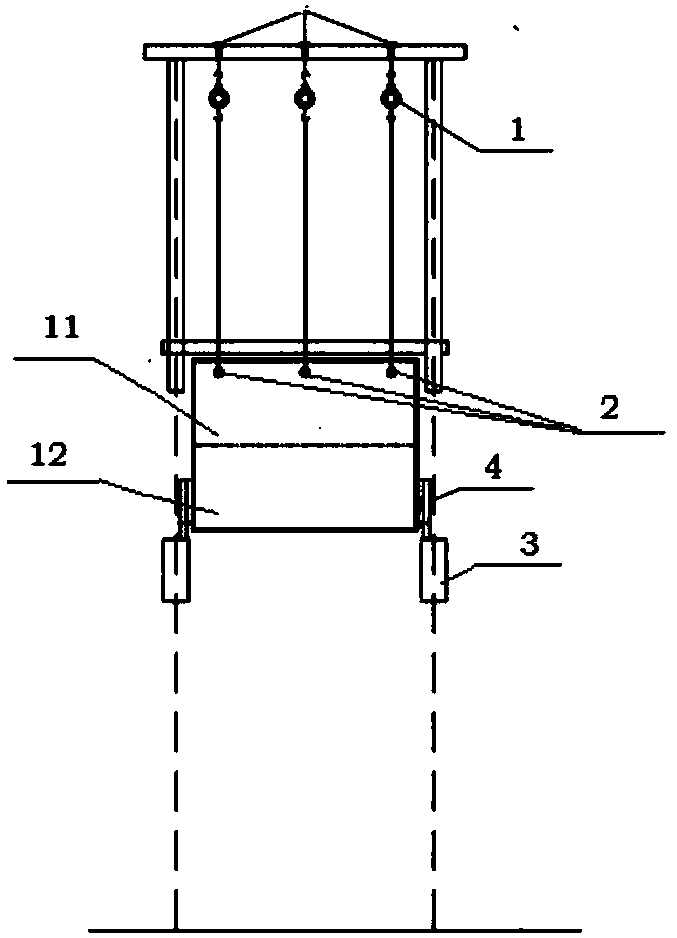

[0035] Such as figure 1 As shown, the installation method of a sintering batching bin in this example is a construction method in which three 10t electric chains are used in the basic frame of the batching room to group and lift the batching batching bins into place, eliminating the need for unlucky transportation. , Large-scale hoisting process, the following will be described in detail in conjunction with the attached drawings:

[0036] S1: Pretreatment of the batching bin before installation: the sintered batching bin is made into loose pieces when manufactured in the processing factory, and the serial number is numbered before leaving the factory. The loose pieces can be installed in groups in the basic frame 5, which is fast in construction and easy to transport. The site space requirements are small. When installing the batching bin, according to actual needs, 3-4 pieces of loose pieces are assembled into a bin body. In this example, each bin is divided into six bins whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com