Modified road asphalt

A road asphalt modification technology, which is applied to building components, building insulation materials, buildings, etc., can solve the problems of roads being easily damaged, and achieve the improvement of asphalt softening point, low temperature crack resistance, and penetration reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

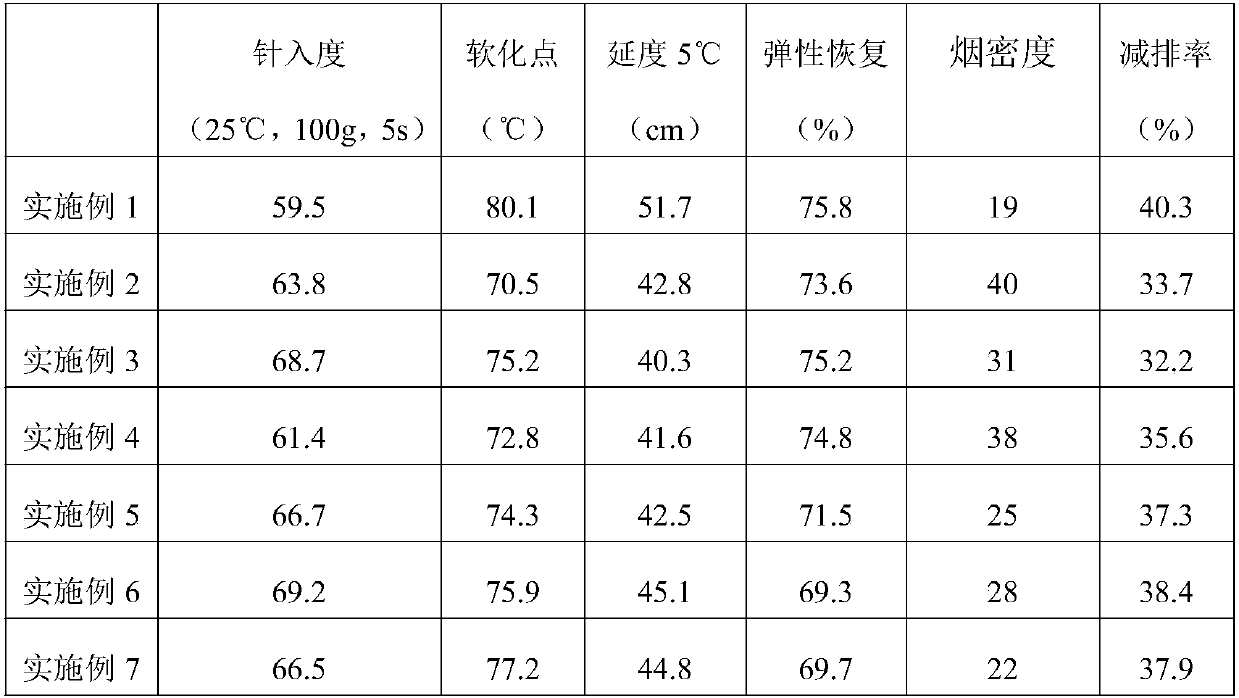

Examples

Embodiment 1

[0029] Modified road asphalt raw materials: 100 parts of asphalt, 9 parts of styrene-butadiene rubber, 5 parts of neoprene rubber, 3 parts of polyvinyl chloride, 1 part of N-isopropyl-N-phenyl-p-phenylenediamine, phthalic acid 4 parts of dimethyl ester, 0.5 part of p-tolualdehyde, 3 parts of flame retardant, and 0.45 part of dispersant.

[0030] The flame retardant is obtained by uniformly stirring and mixing aluminum diethylphosphate, aluminum methylpropionate and aluminum 2-carboxyethylphenylphosphinate in a mass ratio of 1:1:1.

[0031] The dispersant is obtained by stirring and mixing sodium pyrophosphate, potassium tripolyphosphate and sodium stearate uniformly in a mass ratio of 1:1:1.

[0032] The preparation method of modified road asphalt:

[0033] Heat the asphalt to a temperature of 190°C and completely melt it, then add styrene-butadiene rubber, neoprene rubber, polyvinyl chloride, N-isopropyl-N-phenyl-p-phenylenediamine, dimethyl phthalate, p-phenylenediamine To...

Embodiment 2

[0035] It is basically the same as Example 1, the only difference is that the flame retardant is obtained by stirring and mixing aluminum methionyl phosphinate and aluminum 2-carboxyethylphenyl phosphinate in a mass ratio of 1:1 .

Embodiment 3

[0037] It is basically the same as in Example 1, except that the flame retardant is obtained by stirring and mixing uniformly diethylaluminum phosphate and 2-carboxyethylphenylaluminum phosphinate at a mass ratio of 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com