Tunnel secondary lining formwork trolley foot sealing structure and its installation method

A technology of secondary lining and formwork trolley, applied in tunnel lining, tunnel, wellbore lining, etc., can solve the problems of poor surface flatness of the root of secondary lining, lack of attention, explosion mode, etc., so as to improve the quality of concrete and avoid explosion. The effect of reducing the mold phenomenon and reducing the degree of misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention is described further as follows:

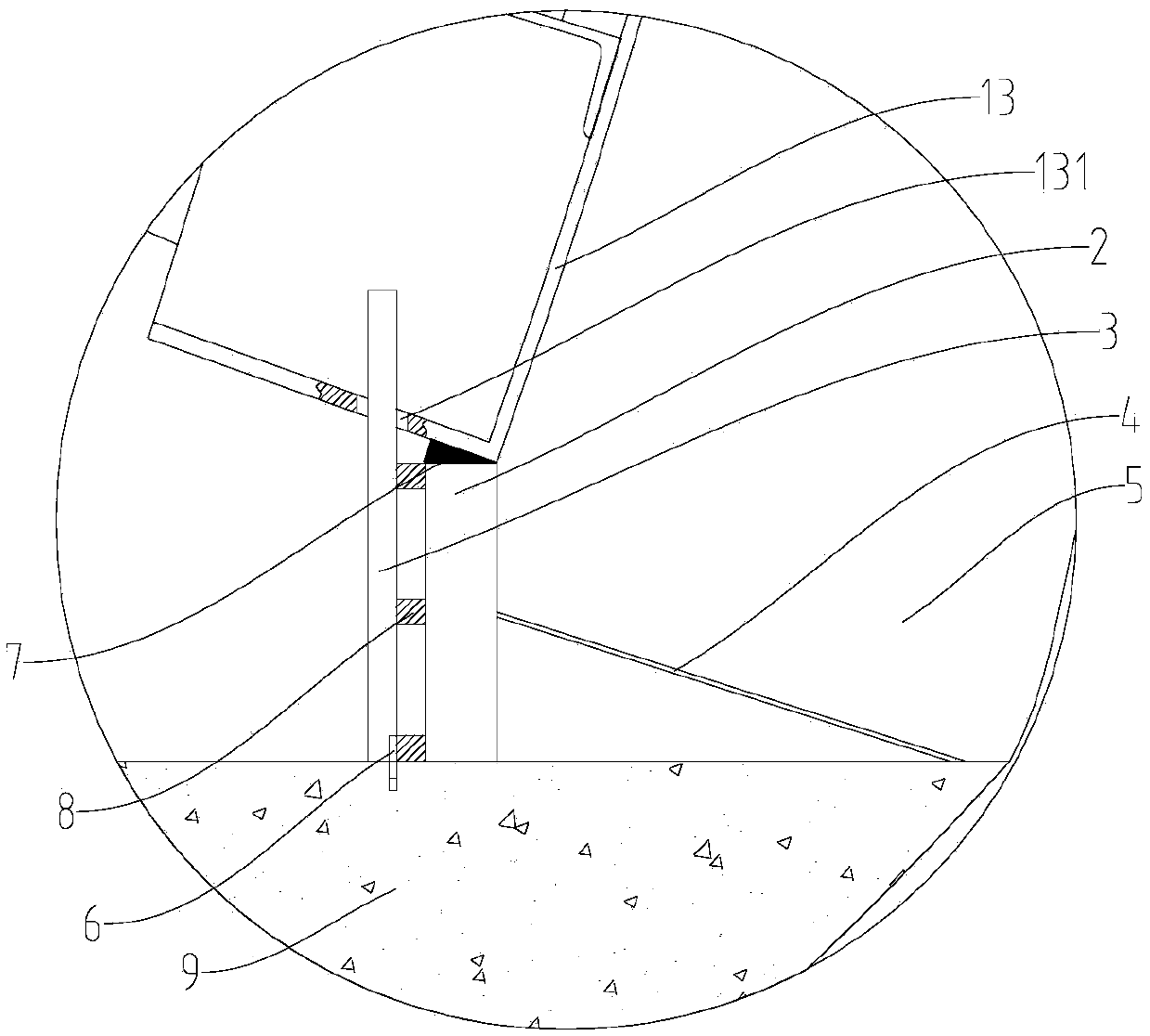

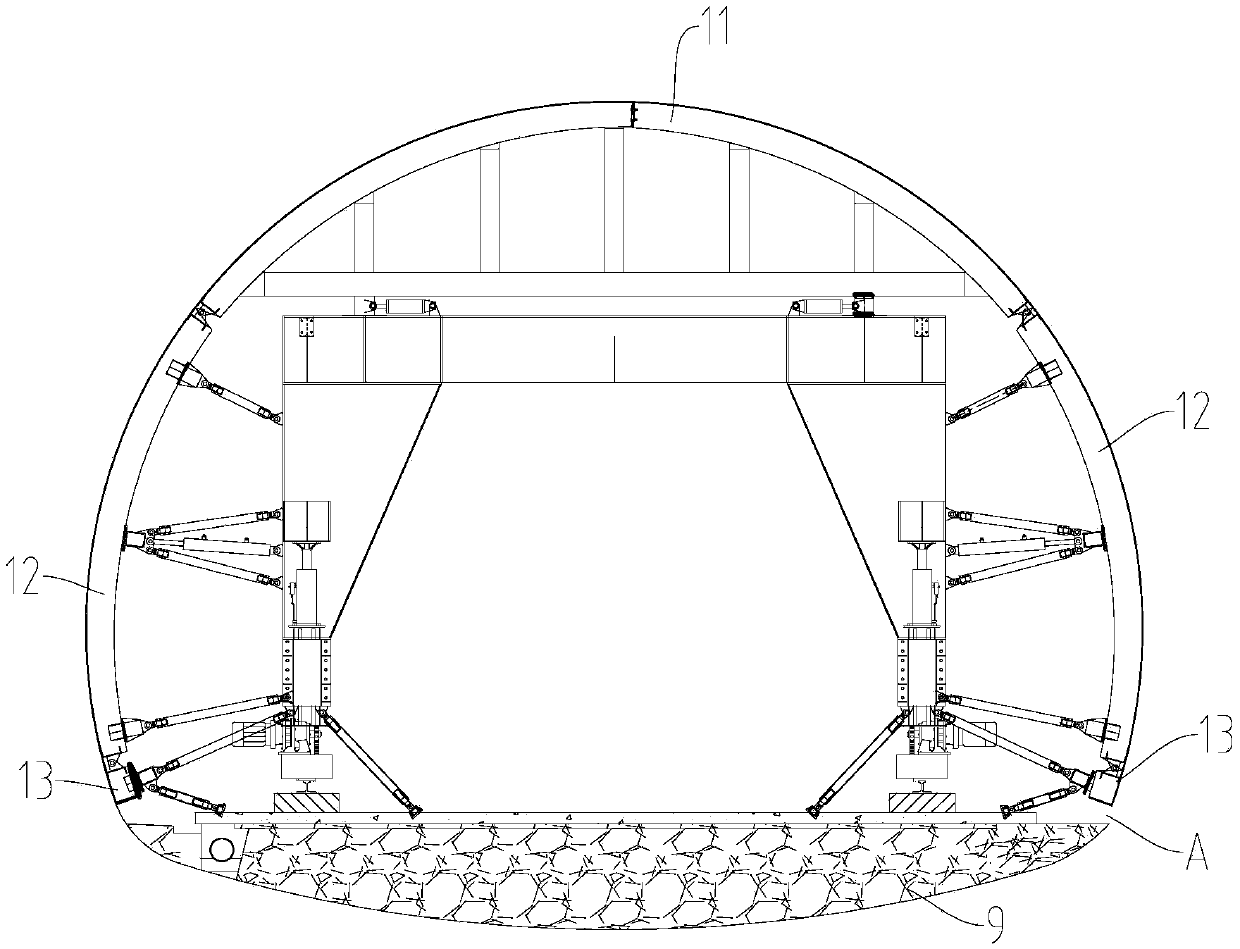

[0024] Tunnel secondary lining formwork trolley foot sealing structure, such as figure 1 As shown, it includes the foot cover formwork 2 located between the hanging form 13 of the tunnel secondary lining formwork trolley and the top surface of the inverted arch, the outer support column 3 located outside the foot cover formwork 2 and the inner support located inside the foot cover formwork 2 Part 4; the top of the working surface of the foot-sealing template 2 extends to the lower end of the working surface of the hanging mold 13, and the bottom extends downward to the surface of the inverted arch; the upper end of the outer support column 3 is installed on the lower end of the hanging mold 13, and the lower end is installed on the inverted arch; one end of the inner support 4 is supported on the foot cover template 2, and the other end is against the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com