Test instrument for material mechanical properties at ultra-high temperature and high-temperature furnace used thereby

A high-temperature furnace and furnace body technology, which is applied in the fields of mechanical performance instruments, high-temperature furnaces with special structures, and ultra-high temperature mechanical performance testing instruments for materials, to achieve the effect of convenient operation and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

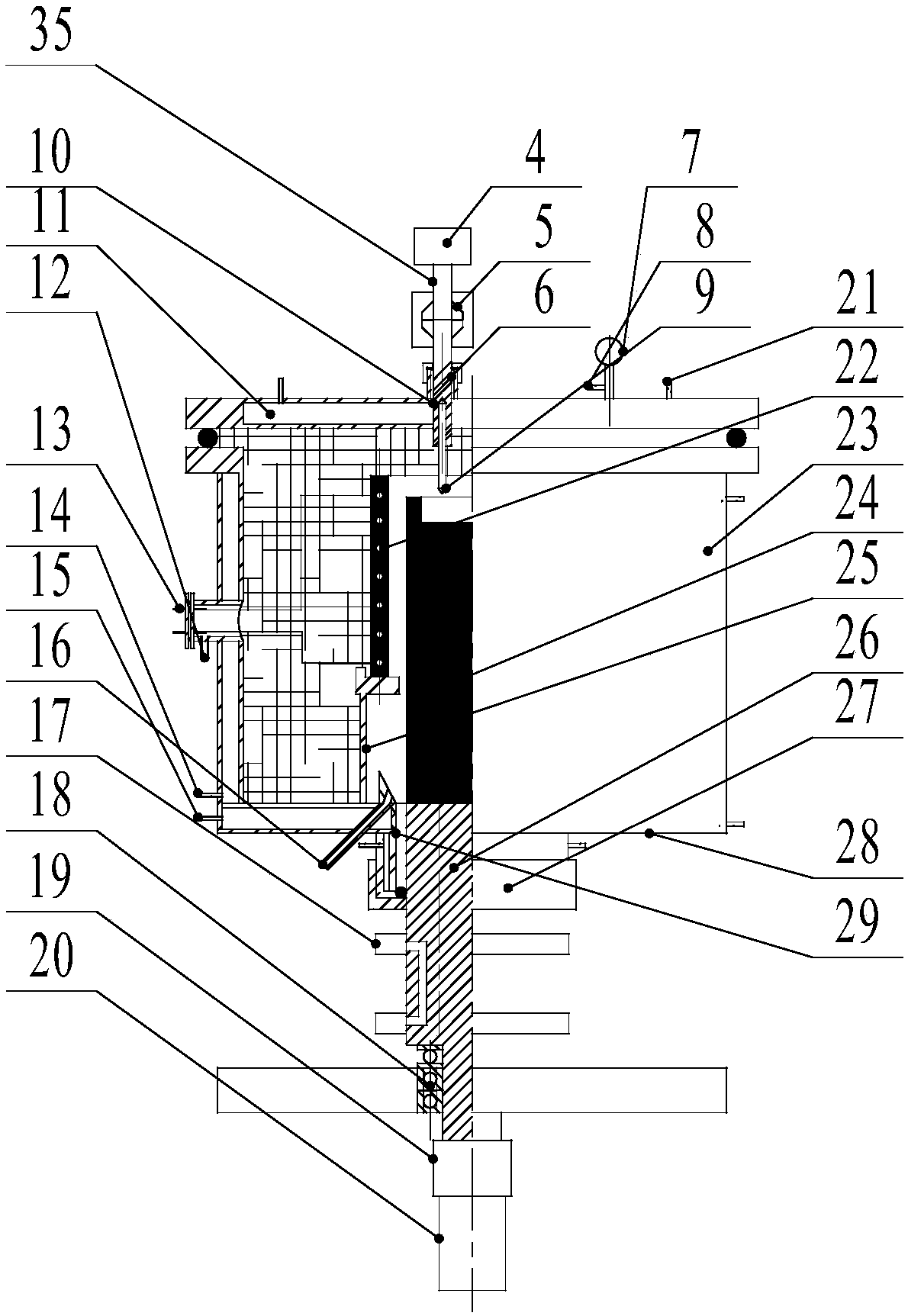

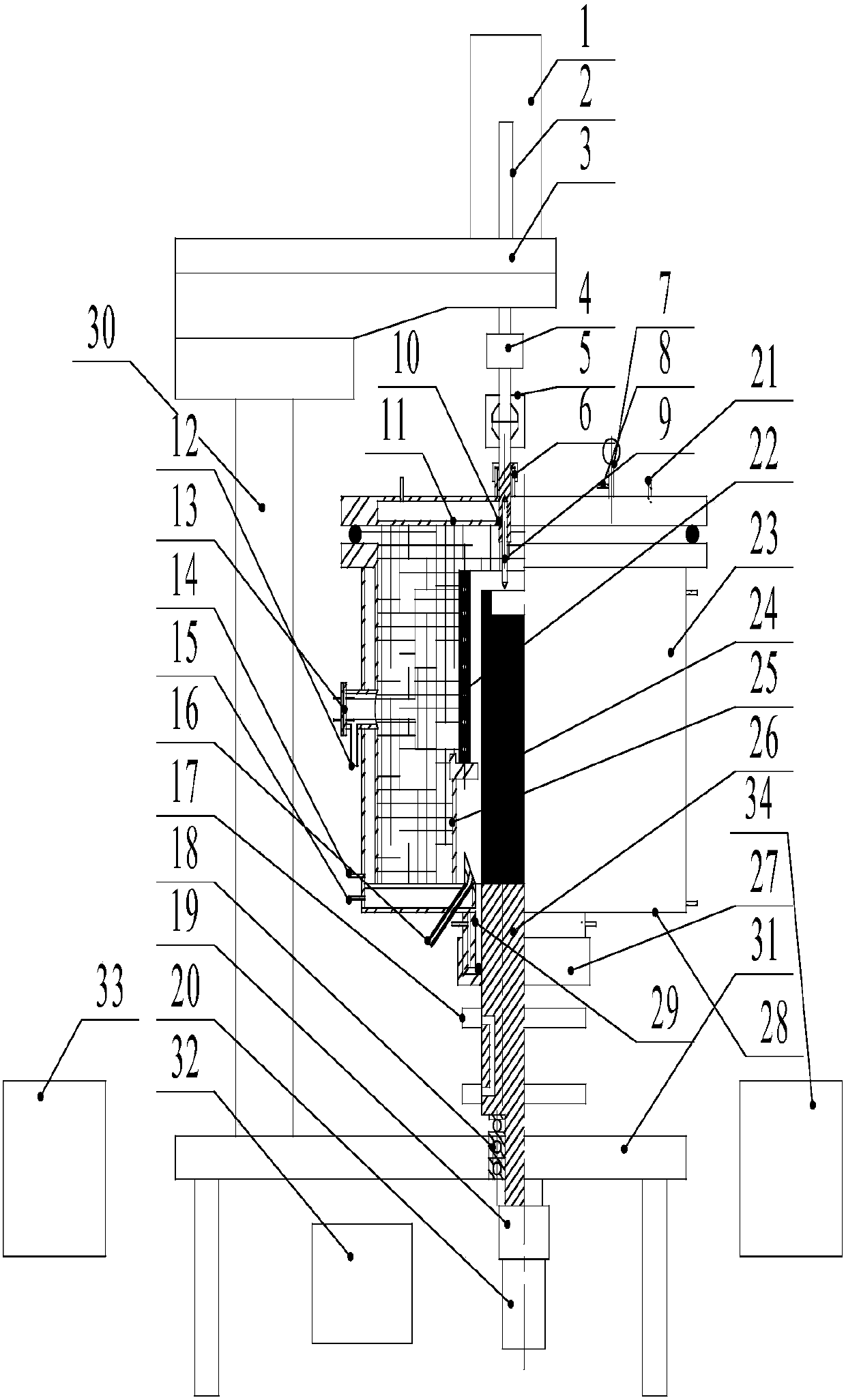

[0037] refer to figure 1 , shows a schematic structural view of an embodiment of the high temperature furnace of the present invention. The high-temperature furnace mainly includes a furnace body 23, a furnace bottom 28, and a furnace cover 11, wherein:

[0038]The furnace body 23 and the furnace cover 11 are connected by a dynamic sealing method. The furnace body 23 and the furnace bottom 28 are integrated by welding and leveling by machining. The through hole 10 stretches into the furnace body 23, and a cubic boron nitride (CBN) pressure head 9 made of a superhard material is set at the end of the pressure rod 35, and a dynamic sealing mechanism 6 is set at the first through hole 10, so as to During the movement of the pressure rod 35, the seal between the pressure rod 35 and the furnace body 23 is maintained. A heating body 22 is arranged in the furnace body 23, and the heating body 22 is fixed in the furnace body 23 by the heating body bracket 25. Boron sample stage 24, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com