7u Modular Wiring Unit for 19" Racks

A wiring unit and modular technology, applied in optical components, fiber mechanical structures, instruments, etc., can solve the problems of difficult construction and limited storage space, saving limited space, facilitating on-site construction, and facilitating later testing and maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

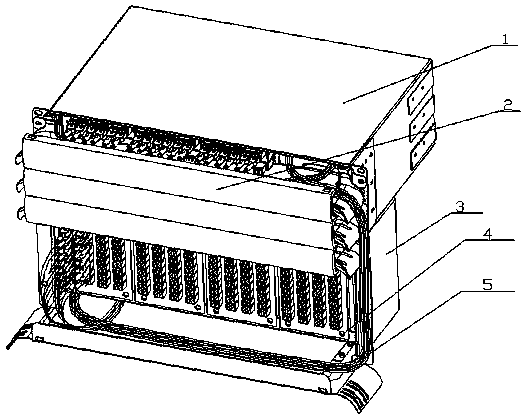

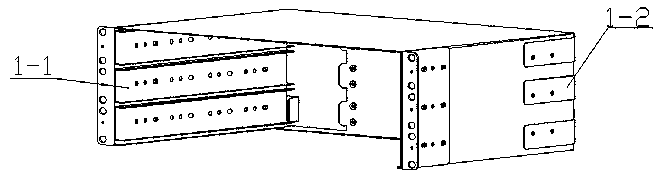

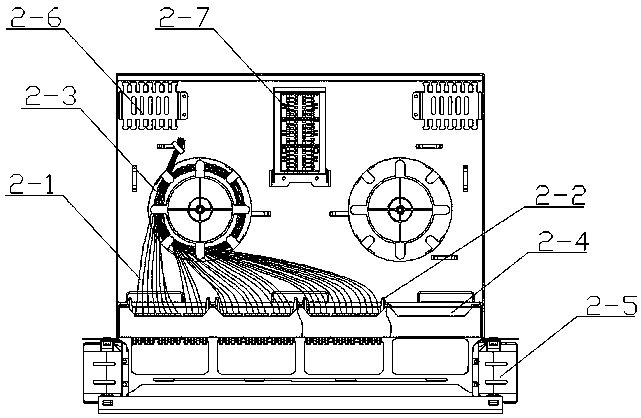

[0039]A 7U modular wiring unit for a 19-inch cabinet, the structure of which includes a box cover 1, a fusion box body 2, an optical splitter box body 3, a plug-in optical splitter 4, and a double-core jumper cable 5; In the distribution box 2, one end of the pigtail 2-1 is connected to the adapter module 2-2, and the other end is coiled on the fiber coil 2-3, and the three fusion distribution boxes 2 pass through the guide rail 1 on the box cover 1 -1 is installed in the box cover 1, the box body 4-1 of the plug-in optical splitter 4 is installed on the optical splitter box body 3 with a plastic lock through the installation hole 3-1, and the The active connector 5-1 is connected to the adapter module 2-2 and the plug-in optical splitter 4, and a part of the redundant optical fiber 5-2 is stored in the fiber storage area 2-4 of A and then fixed on the cable management ear 2-5 with Velcro , the remaining optical fiber 5-2 is stored on the fiber storage area 3-3 of B and fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com