Assembling method for preservative oil immersion type amorphous transformer iron core

A technology of amorphous iron core and assembly method, which is applied in inductance/transformer/magnet manufacturing, magnetic core manufacturing, electrical components, etc., can solve problems such as winding short circuit, affecting the quality of amorphous transformer, etc., so as to reduce the probability of short circuit and reduce The probability of occurrence, the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

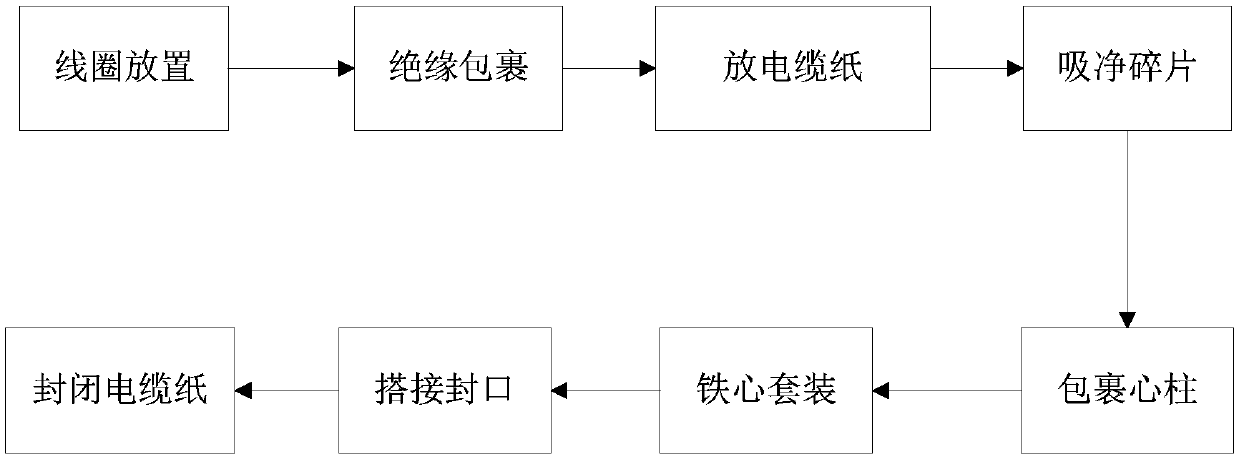

[0031] Such as figure 1 As mentioned above, a protective oil-immersed amorphous transformer core assembly method disclosed in the embodiment of the present invention includes the following steps:

[0032] (1) The qualified coils on the roller table will be hoisted on the brackets of the assembly table according to the phase sequence;

[0033] (2) Wrap the contact part of the coil with the amorphous core with cable paper;

[0034] (3) Place the upper and lower yoke cable papers of the integral iron core in the inner frame of the coil, and fix the cable papers with adhesive tape along the coil window;

[0035] (4) Hoist the amorphous iron core to the hydraulic flatbed truck in sequence according to the assembly sequence with a special magnetic hoist, and use a vacuum cleaner to clean the amorphous fragments on the iron core;

[0036] (5) Wrap the part of the amorphous iron core column with noise-reducing cable paper (the iron core tape produced by Nantong Rizhi can be used); ...

Embodiment 2

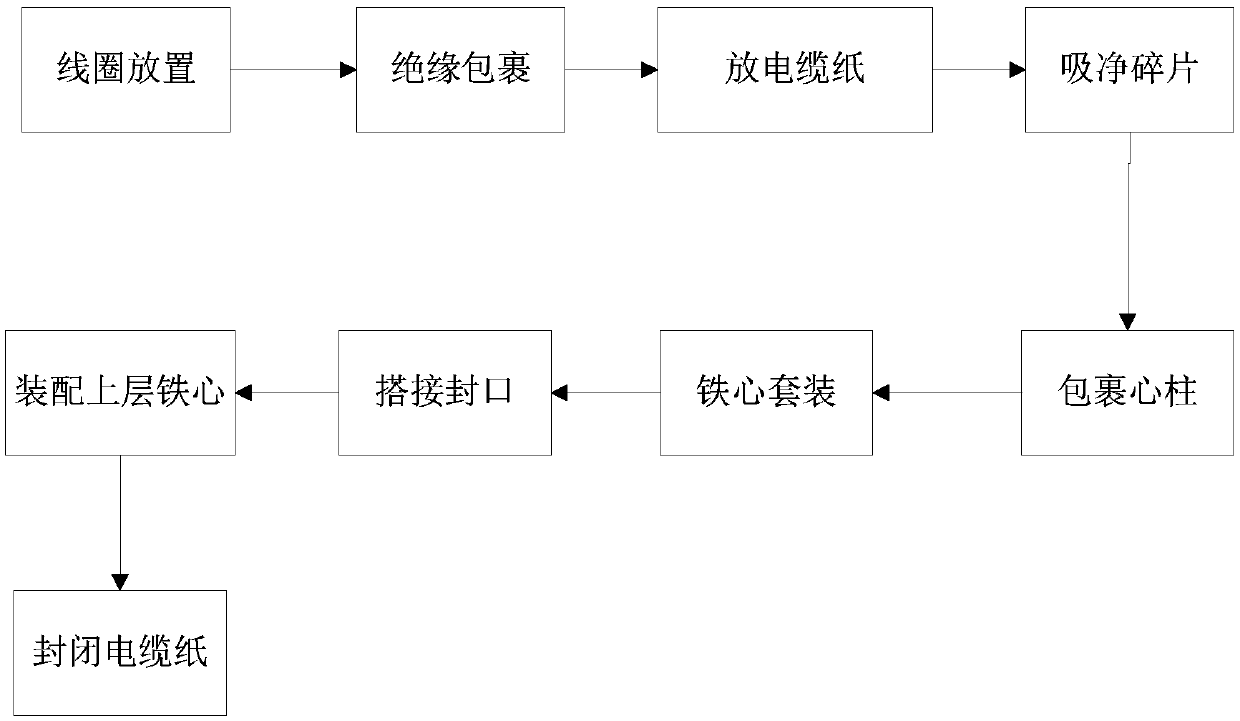

[0043] Such as figure 2 As mentioned above, a protective oil-immersed amorphous transformer core assembly method disclosed in the embodiment of the present invention includes the following steps:

[0044] (1) The qualified coils on the roller table will be hoisted on the brackets of the assembly table according to the phase sequence;

[0045] (2) Wrap the contact part of the coil with the amorphous core with cable paper;

[0046] (3) Place the upper and lower yoke cable papers of the integral iron core in the inner frame of the coil, and fix the cable papers with adhesive tape along the coil window;

[0047] (4) Hoist the lower layer of amorphous iron cores to the hydraulic flatbed truck in sequence according to the assembly sequence with a special magnetic lifter, and use a vacuum cleaner to clean the amorphous fragments on the iron cores;

[0048] (5) Wrap the part of the amorphous core column with noise-reducing cable paper;

[0049] (6) Open the amorphous core by stack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com