A kind of CT equipment and its dedusting method

A technology of equipment and dust removal device, which is applied in the field of CT equipment and its dust removal, can solve the problems that are not conducive to the efficient use of equipment, more manpower for disassembly and installation, and insufficient cleaning of equipment, so as to save dust removal time, simplify equipment and reduce maintenance cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to more clearly illustrate the technical solutions of the embodiments of the present application, the following briefly introduces the drawings that need to be used in the description of the embodiments.

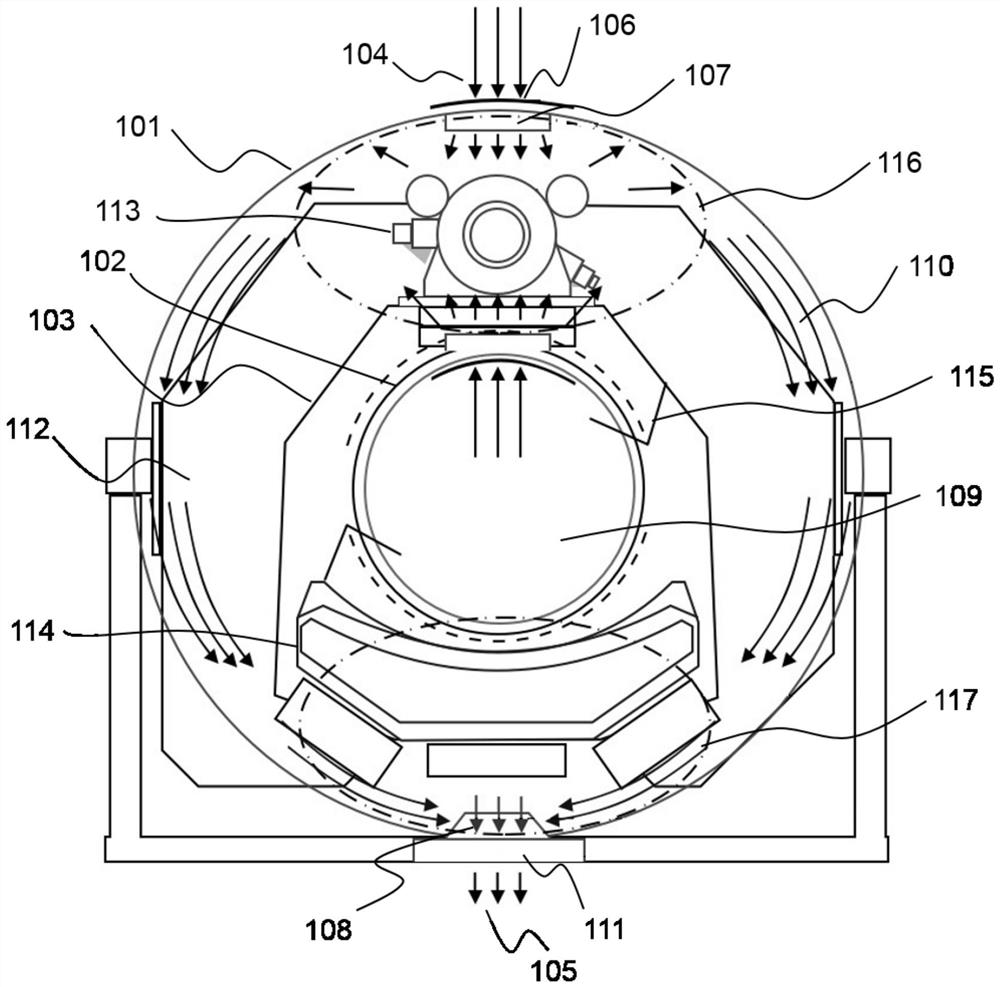

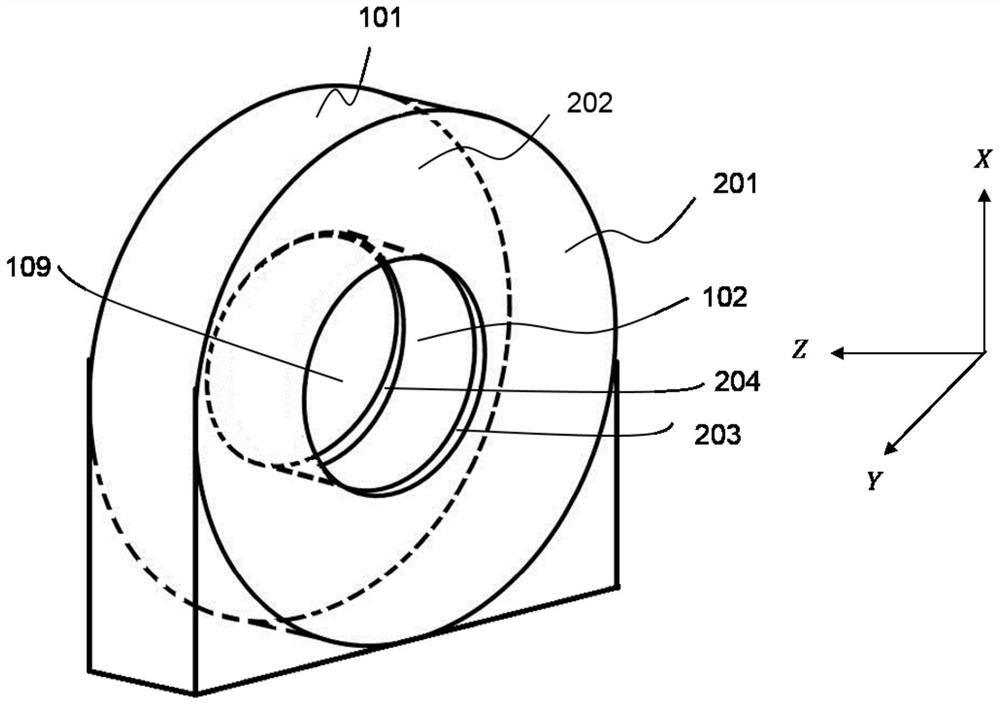

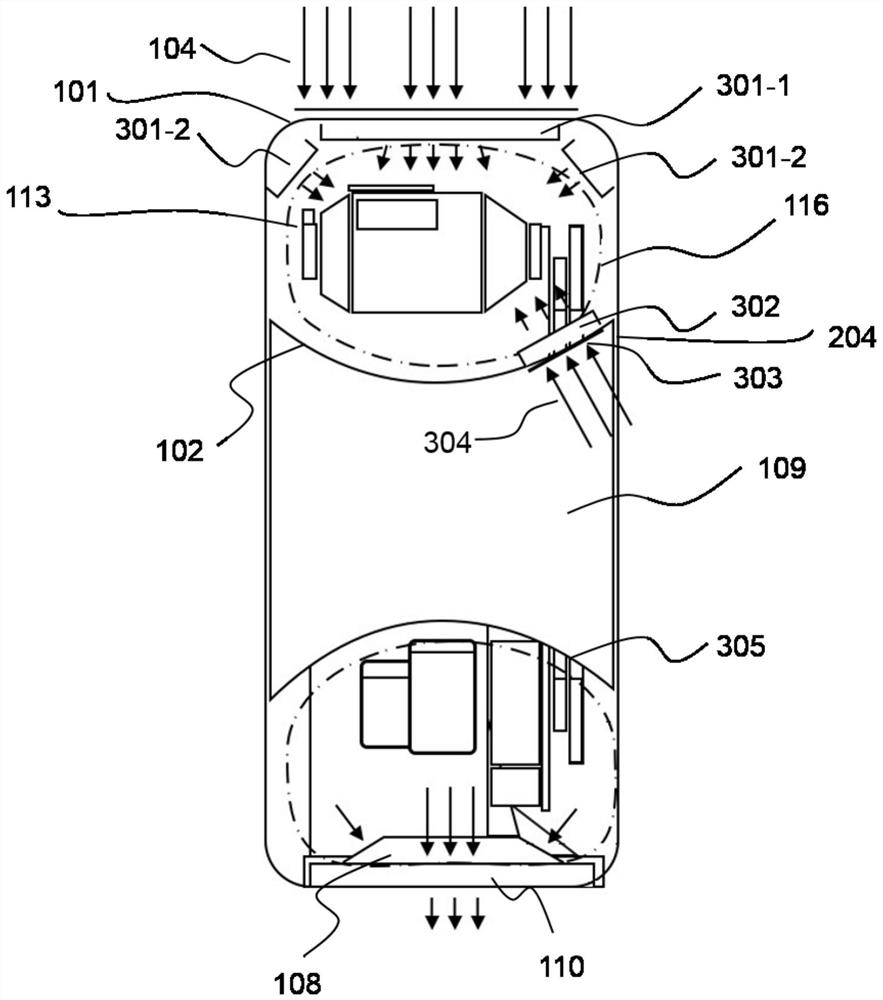

[0036] Such as figure 1 As shown, the CT equipment 100 may include an outer casing 101, an inner casing 102, a rotatable frame 103 and a dust removal device. The dust removal device is arranged on the casing. The dust removal device may include an air inlet 104 , an air outlet 105 , a protective filter 106 , an intake fan 107 and an exhaust fan 108 . The air inlet end 104 and the air outlet end 105 of the dust removal device may be connected through an air duct 110 . The CT apparatus 100 may further include a solid state impurity collector 111 .

[0037] A hollow chamber 112 is formed between the outer casing 101 and the inner casing 102 , and the rotatable frame 103 is disposed inside the hollow chamber 112 . Equipment components are arranged on the rack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com