A self-circulating hydrogen peroxide desulfurization process

A desulfurization process, hydrogen peroxide technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as inability to use desulfurization technology, and achieve highly targeted effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

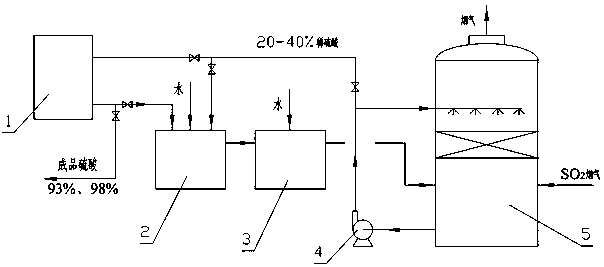

[0028] When the desulfurization tower 5 adopts an empty tower structure, the self-circulating hydrogen peroxide desulfurization process flow of the present invention is as follows: first, the finished sulfuric acid from the sulfuric acid absorption tower 1 is mixed with the water from the water pipe and / or from the sulfuric acid with a concentration of 20% to 40%. The dilute sulfuric acid in the delivery pipe of the dilute sulfuric acid is configured in the electrolytic cell 2 to form a sulfuric acid solution with a concentration of 50% to 60%; the electrolytic cell 2 uses an inert electrode to electrolyze the sulfuric acid solution with a concentration of 50% to 60%. Peroxodisulfuric acid is generated under the environment; peroxodisulfuric acid is transported to the hydrolysis tank and hydrolyzed to generate a mixed solution of dilute sulfuric acid and hydrogen peroxide; the mixed solution is added to the desulfurization tower 5 through the mixed solution output pipe as 2 The...

Embodiment 2

[0030] When the desulfurization tower 5 adopts a packed tower structure, the self-circulating hydrogen peroxide desulfurization process flow of the present invention is as follows: first, the finished sulfuric acid from the sulfuric acid absorption tower 1 is mixed with the water from the water pipe and / or from the sulfuric acid with a concentration of 20% to 40%. The dilute sulfuric acid in the delivery pipe of the dilute sulfuric acid is configured in the electrolytic cell 2 to form a sulfuric acid solution with a concentration of 50% to 60%; the electrolytic cell 2 uses an inert electrode to electrolyze the sulfuric acid solution with a concentration of 50% to 60%. Peroxodisulfuric acid is generated under the environment; peroxodisulfuric acid is transported to the hydrolysis tank and hydrolyzed to generate a mixed solution of dilute sulfuric acid and hydrogen peroxide; the mixed solution is added to the desulfurization tower 5 through the mixed solution output pipe as 2 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com