Rubber sleeve for dobby drill and propeller and preparation method thereof

A technology of rubber sleeves and blocks, which is applied in the direction of drilling equipment, drill pipes, drill pipes, etc., can solve the problems of high cost, inconvenient procurement, and short use and replacement cycles of rubber sleeves for drill propellers, and achieve labor saving and structure replacement. Simple and practical, the effect of long replacement cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Due to the backward development of the local area, there are no such accessories in the local area and neighboring countries, so the nearby purchase can only be given up. Observation and analysis of the rubber sleeve of the drill supporter shows that this accessory must be wear-resistant, tough and elastic, and can hold the drill pipe well on the boom of the drilling rig. After analysis, at this time the artificial aggregate production system on the construction site has replaced many scrapped conveyor belts, which happen to have properties such as wear resistance, toughness, and elasticity, and the conveyor belt contains multiple layers of fibers, which have better toughness and stability. Using the scrapped aggregate conveyor belt of the artificial aggregate production system, a durable and replaceable rubber sleeve for the brazing device was designed and manufactured, successfully turning waste into treasure.

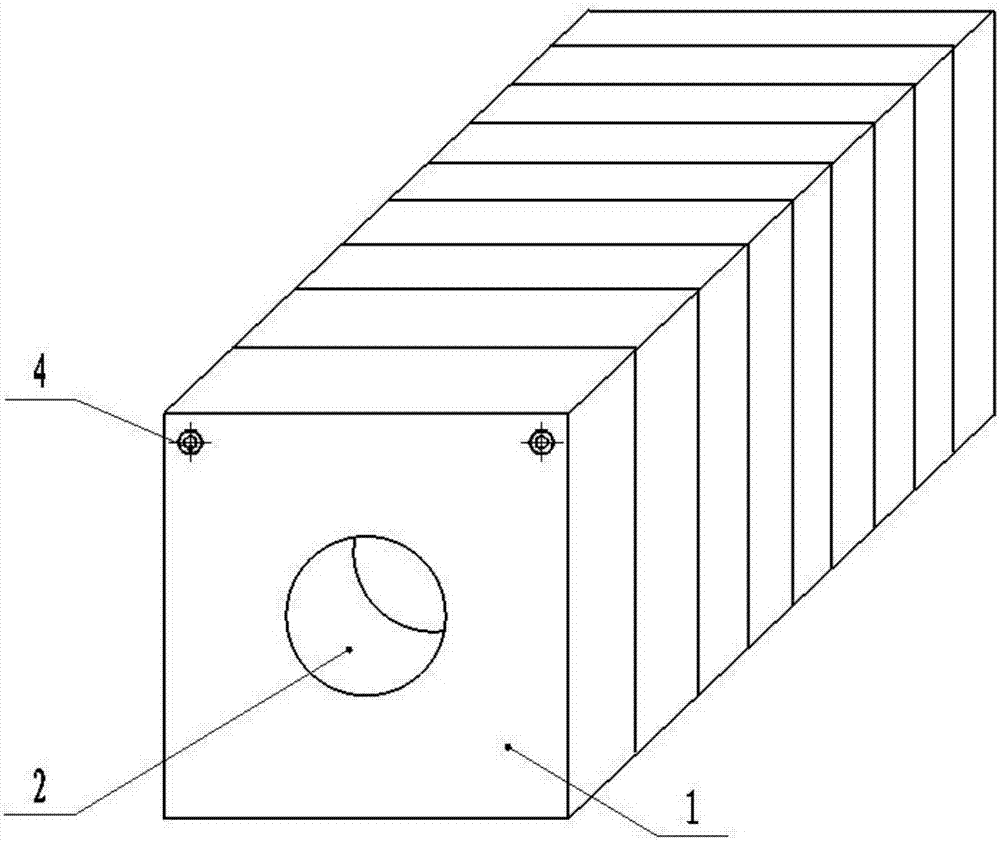

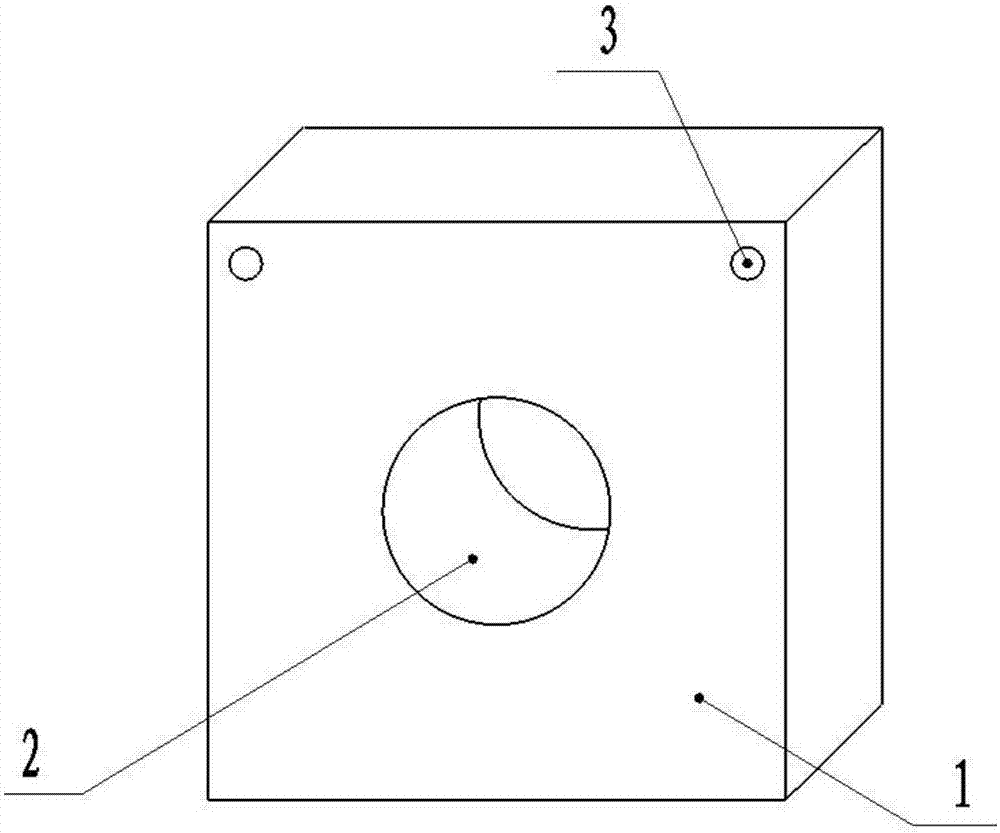

[0031] Such as Figure 2-3 Shown, a kind of dobby drill...

Embodiment 2

[0047] Such as Figure 2-3 Shown, a kind of multi-arm drilling propeller rubber sleeve of the present invention, the long 11cm of brazing device rubber sleeve before making (can determine the making size of brazing device rubber sleeve according to actual needs), wide and high 8cm, the center is diameter 4cm hole. The scrap aggregate conveying width is 650cm~1000cm, and the thickness is 1.1~1.2cm. Cut the conveyor belts of different widths into 8cm×8cm aggregate conveyor belt block 1 with a shearing machine (you can also install the self-made blade on the four-post press to cut the strips); D=4cm) extrude the circular drill pipe through hole 2, open the installation hole 3 (D=6mm) respectively with a four-column press at two corners on one side, the center of the hole is 1cm from the adjacent two sides, when opening the hole, It is best to make a right-angled L-shaped slot and fix the aggregate conveyor belt block 1 on the drilling machine to prevent the block from rotating ...

Embodiment 3

[0049] Such as Figure 2-3 Shown, a kind of preparation method of dobby drill propeller rubber sleeve, comprises steps:

[0050] Step 1, using the scrapped aggregate conveyor belt to cut and make the aggregate conveyor belt block 1;

[0051] Step 2, opening a drill pipe through hole 2 at the center of the aggregate conveyor belt block 1;

[0052] Step 3. Open a mounting hole 3 at two corners of one side of the aggregate conveyor belt block 1;

[0053] Step 4. Stack nine aggregate conveyor belt cubes 1, and use bolts 4 to connect and fix the superimposed aggregate conveyor belt cubes 1 in series through installation holes 3 to form a brazing device rubber sleeve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com