Starch pasting heating barrel

A technology of starch gelatinization and heating barrel, applied in chemical instruments and methods, chemical/physical processes, mixers, etc., can solve the problems of high power consumption and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

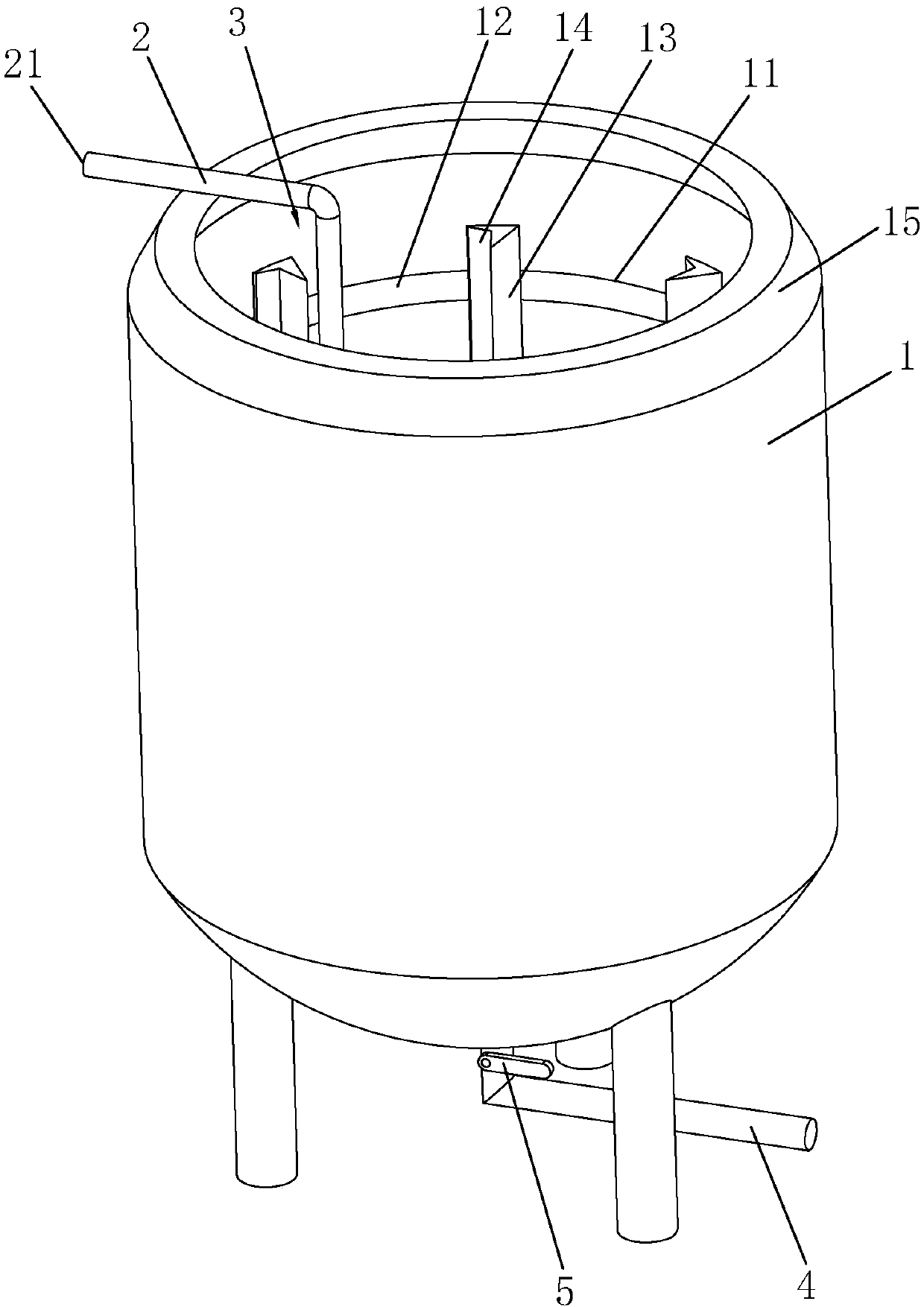

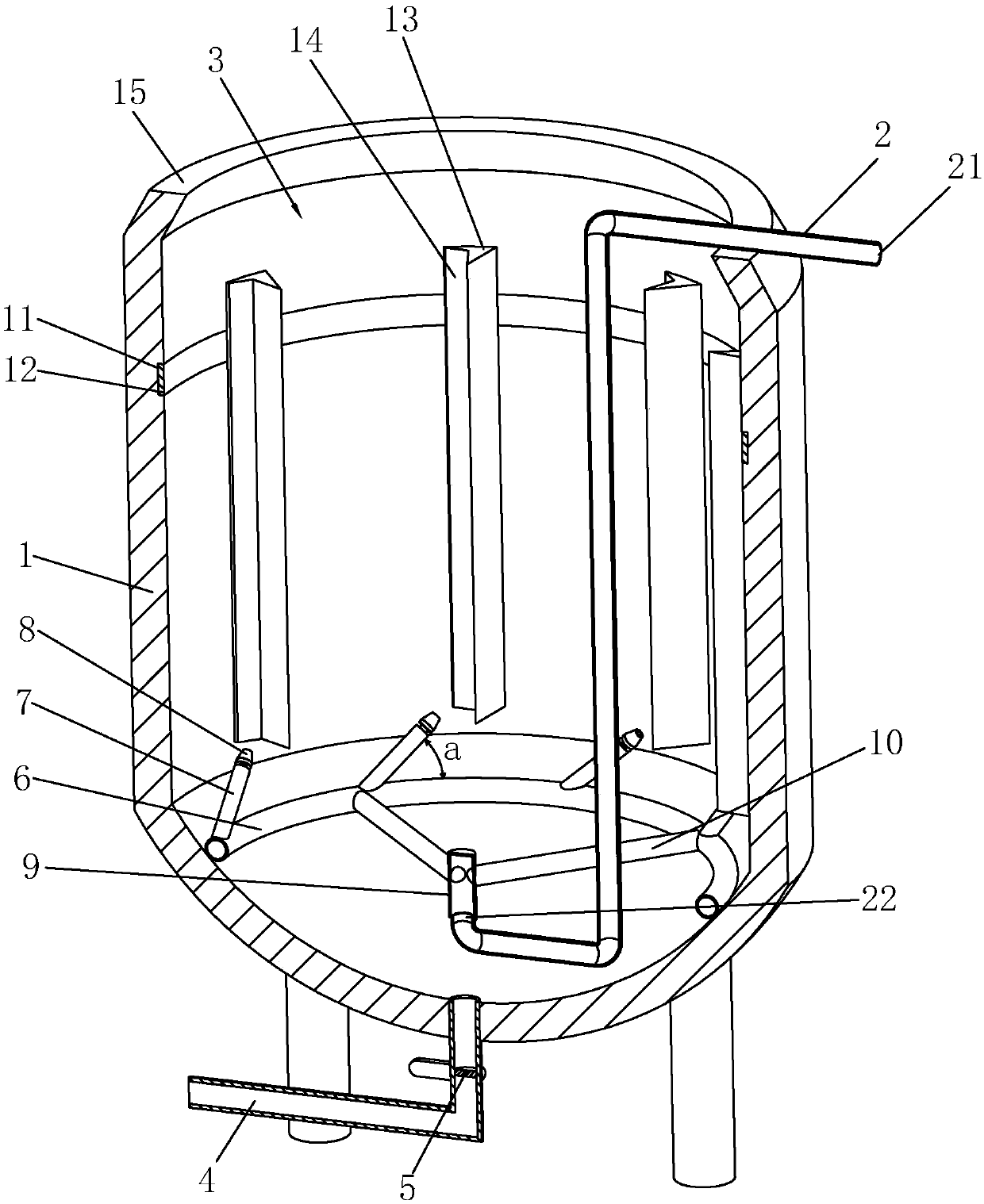

[0031] A starch gelatinization heating barrel, such as figure 1 , figure 2 As shown, a barrel body 1 and a steam pipe 2 are included. An opening 3 is provided on the top of the barrel body 1, and starch can be put into the barrel body 1 through the opening 3 when the heating barrel needs to be used. A material blocking cover 15 is provided at the opening 3 . The cross-sectional shape of the material blocking cover 15 is circular and the cross-sectional area of the material blocking cover 15 gradually decreases toward the side away from the opening 3 . A discharge pipe 4 is arranged at the bottom of the barrel body 1 and the discharge pipe 4 communicates with the inside of the barrel body 1 . The connecting pipe 9 is provided with a valve 5 for controlling the opening or closing of the connecting pipe 9 . When the gelatinization of the starch inside the barrel 1 is completed, the valve 5 on the connecting pipe 9 is opened, and then the starch inside the barrel 1 flows int...

Embodiment 2

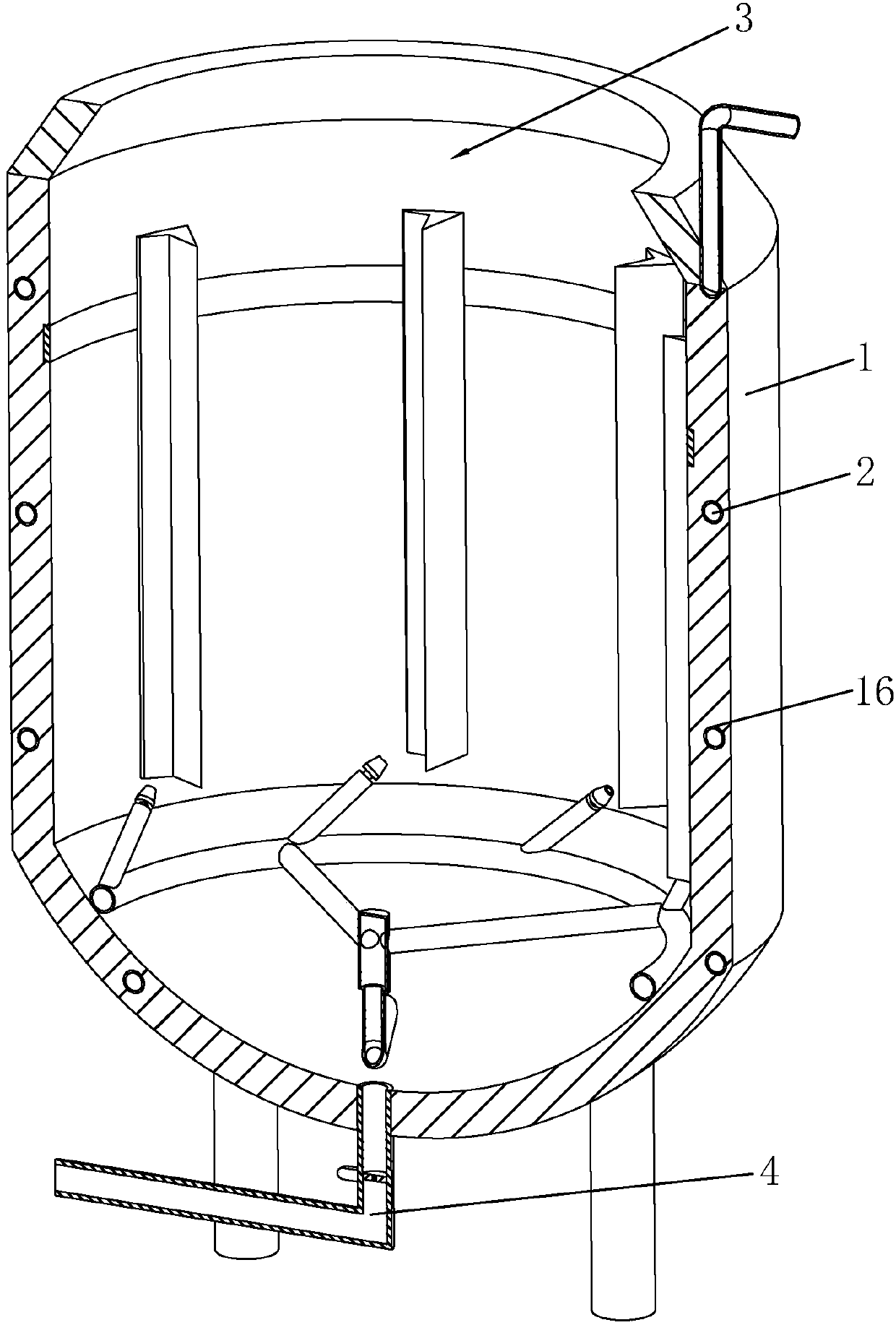

[0038] The difference between the second embodiment and the first embodiment is that a spiral mounting hole 16 is provided on the inner wall of the barrel body 1, and one end of the mounting hole 16 extends toward the side of the opening 3 and runs through the top surface of the barrel body 1, and the other end of the mounting hole 16 It extends toward one side of the discharge pipe 4 and penetrates through the inner wall of the bucket body 1 . The steam pipe 2 is arranged inside the installation hole 16 and the outer wall of the steam pipe 2 is against the inner wall of the installation hole 16 . When the hot steam flows through the steam pipe 2, the heat contained in the hot steam is transferred to the inside of the barrel body 1 through the wall of the steam pipe 2, so that the temperature of the inner wall of the barrel body 1 gradually increases. In this way, in the process of using the heating barrel to gelatinize the starch, the starch inside the barrel body 1 is not ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com