Use method of forging furnace for steel structure building material processing

A technology for forging furnaces and steel structures, which is applied in the field of forging furnaces for processing steel structure building materials, can solve the problems of high labor intensity and reduce labor intensity of workers, so as to ensure personal safety, reduce labor intensity, and avoid working under high temperature conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

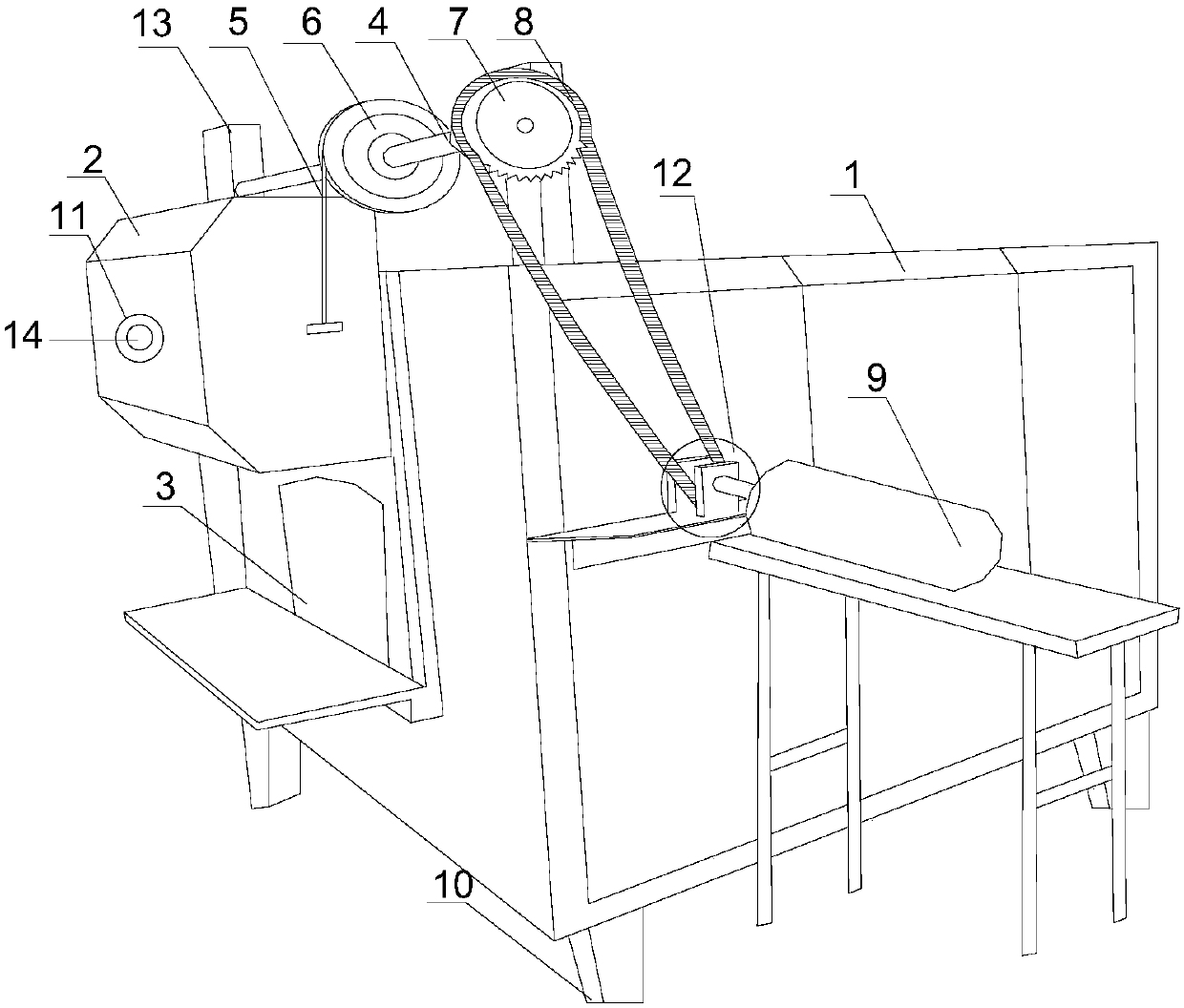

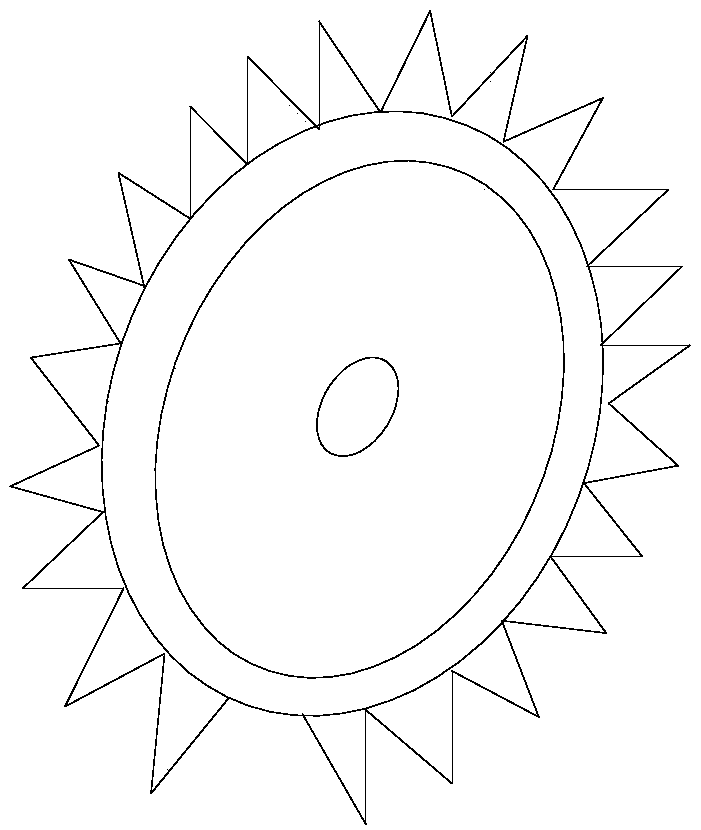

[0018] like figure 1 and figure 2 As shown, the furnace cover adopted by the heating furnace of the present invention is horizontally slidably arranged, and the furnace cover is installed on the front end of the feed port in a longitudinally slidable manner, and the motor can rotate in positive and negative directions. Realize the upper and lower opening and closing of the furnace cover, which can replace the manual operation to quickly complete the opening and closing of the furnace cover, so that the staff can stay away from the forging heating furnace, and realize remote automatic operation. The manual drive is replaced by the motor drive, which improves work efficiency and reduces the number of workers. labor intensity, wherein, the side of the furnace body 1 is also provided with a feed inlet 3, the feed inlet 3 is located on the motion track of the furnace cover 2; it also includes a motor 9 and a tension adjustment mechanism connected with the furnace cover 2, the moto...

Embodiment 2

[0021] like figure 1 As shown, on the basis of Embodiment 1, this embodiment also includes the interconnected temperature sensor 11 and alarm 14 installed on the furnace cover 2. The heating equipment will generate a large amount of heat energy, especially at the feed inlet 3. Can be subjected to more heat on the furnace cover 2 as sealing member, be easy to scald the worker, the temperature sensor 11 that is provided with alarm 14, can have alarm 14 to send warning sound when temperature is higher, avoids the worker Work under high temperature conditions to reduce the occurrence of safety accidents.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com