Device capable of achieving precise angle cutting of profile

A precision and angle technology, which is applied in the field of devices capable of cutting profiles with precision angles, can solve the problems of inability to accurately locate non-90° cutting angles, troublesome angle adjustments, cumbersome operations, etc., to achieve improved cutting efficiency, convenient operation, and guaranteed The effect of cutting safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

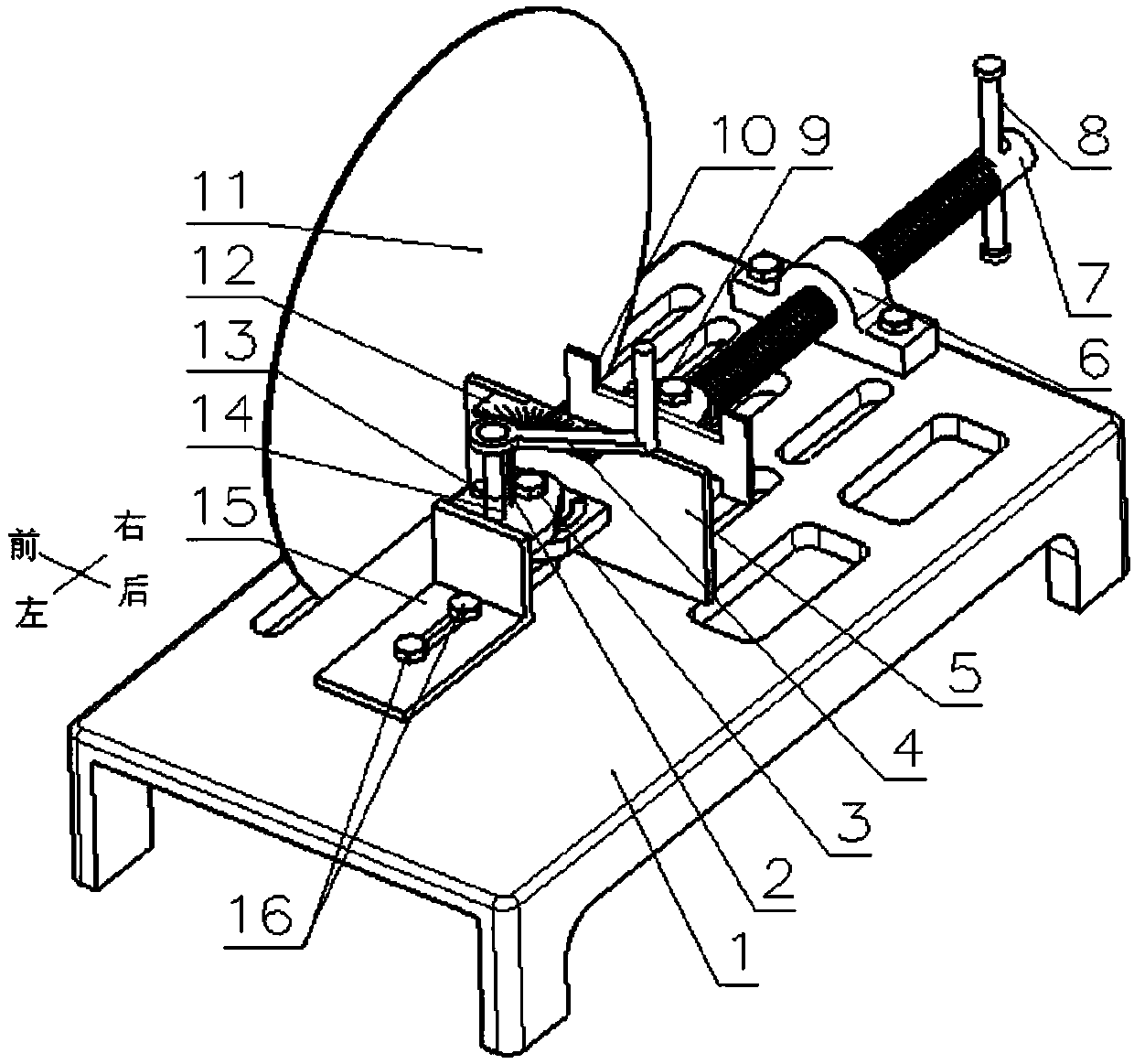

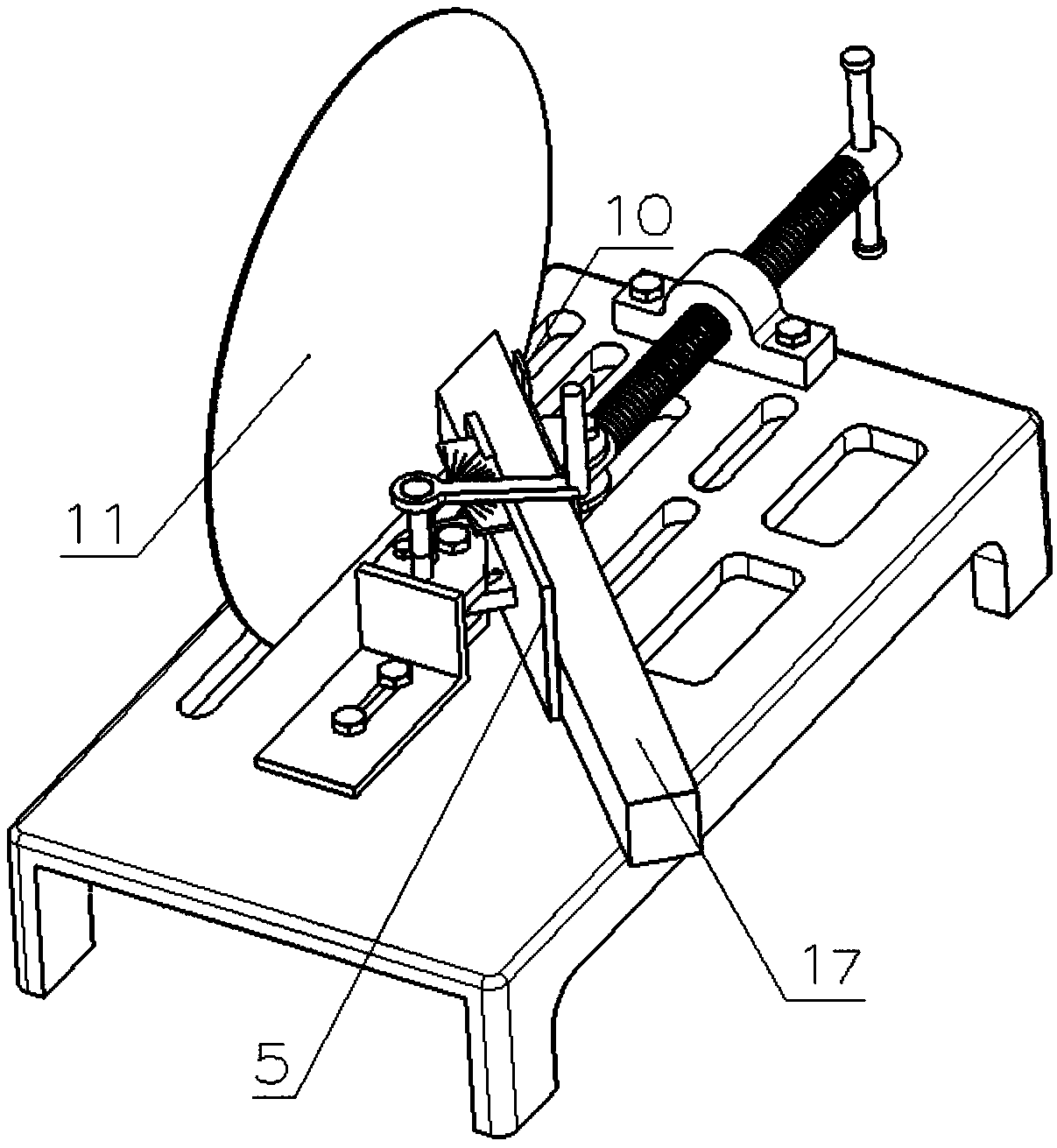

[0027] Such as figure 1 The shown device capable of precise angle cutting of profiles includes a base 1, a lead screw nut seat 6, a lead screw 7, a follower platen 10, a cutting assembly and an angle positioning mechanism. Described leading screw nut seat 6 is fixed on the right side of base 1, and described leading screw 7 is arranged horizontally along the left-right direction, and leading screw 7 and leading screw nut seat 6 are threadedly connected, and the right end of leading screw 7 is provided with tight Solid rod 8. The follower platen 10 is connected to the left end of the lead screw 7 through the first rotating shaft 9 . The cutting assembly includes a cutting blade 11 and a driving motor (not shown in the figure, etc.).

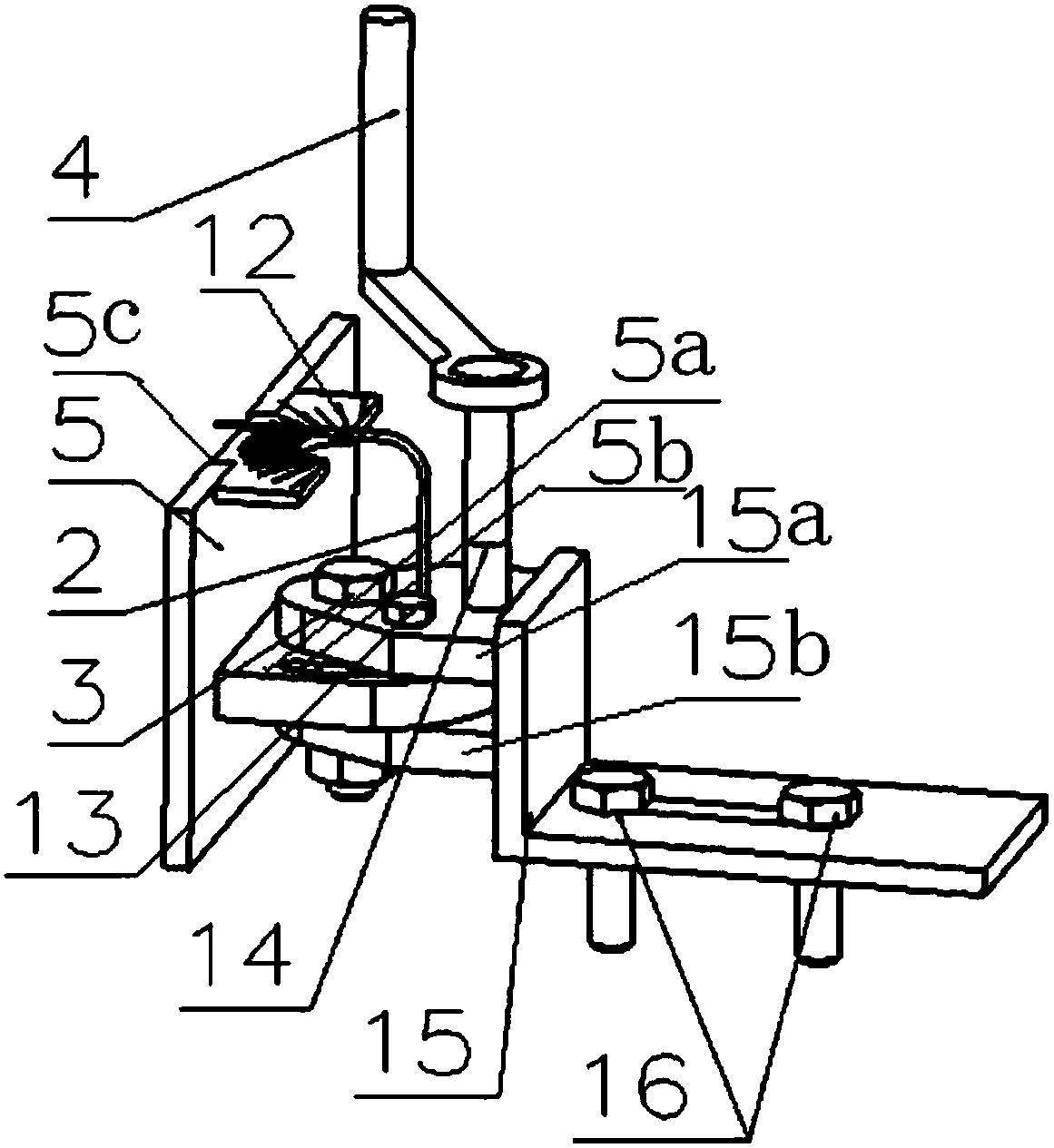

[0028] Such as figure 2 As shown, the angle positioning mechanism includes a pointer 2, a second rotating shaft 3, a fastening plate 5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com