Automatic material loading device for tubular element

A technology for automatic feeding and tubular parts, which is applied in metal processing and other directions, and can solve problems such as inability to ensure grasping, complex structure, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

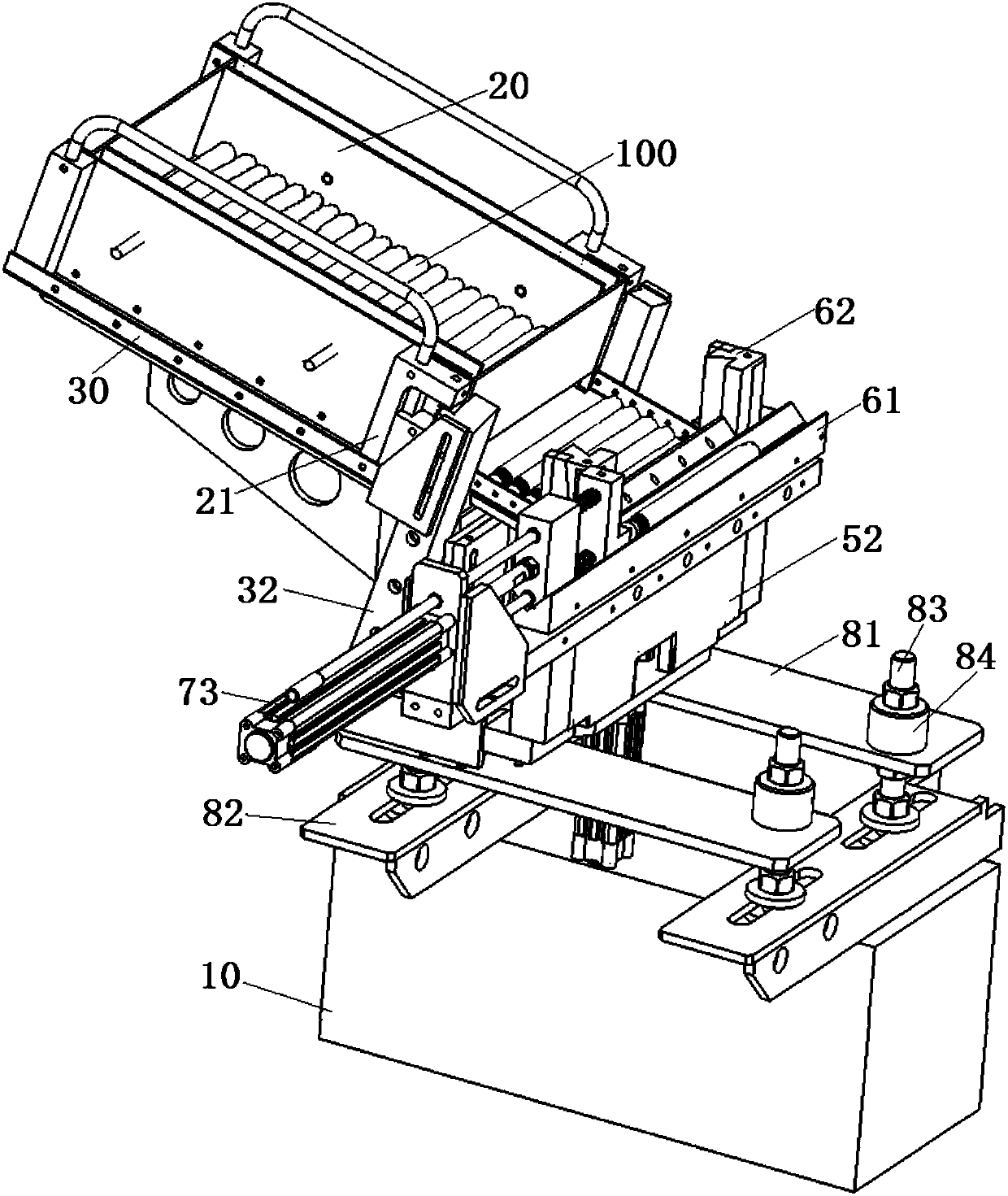

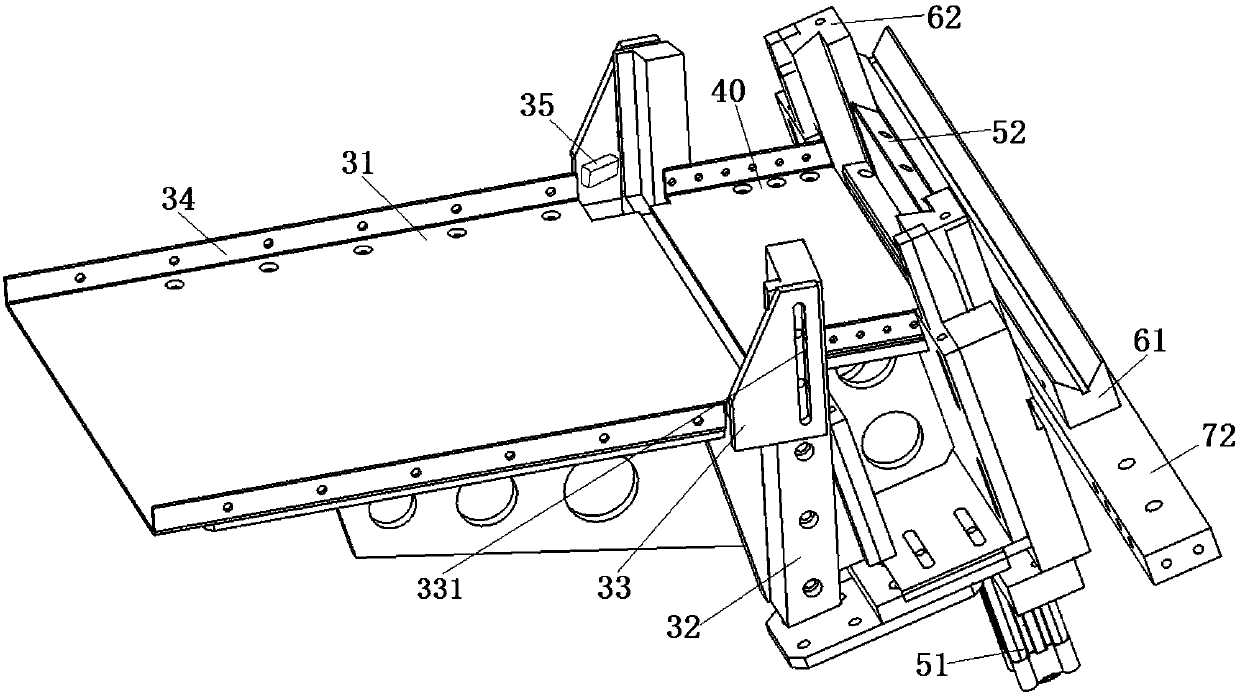

[0024] see Figure 1 to Figure 5 , an automatic feeding device for a tubular member 100 according to the present invention includes a workbench 10 and a feeding mechanism, a material shifting mechanism and a material discharging mechanism arranged on the workbench 10 in sequence from back to front.

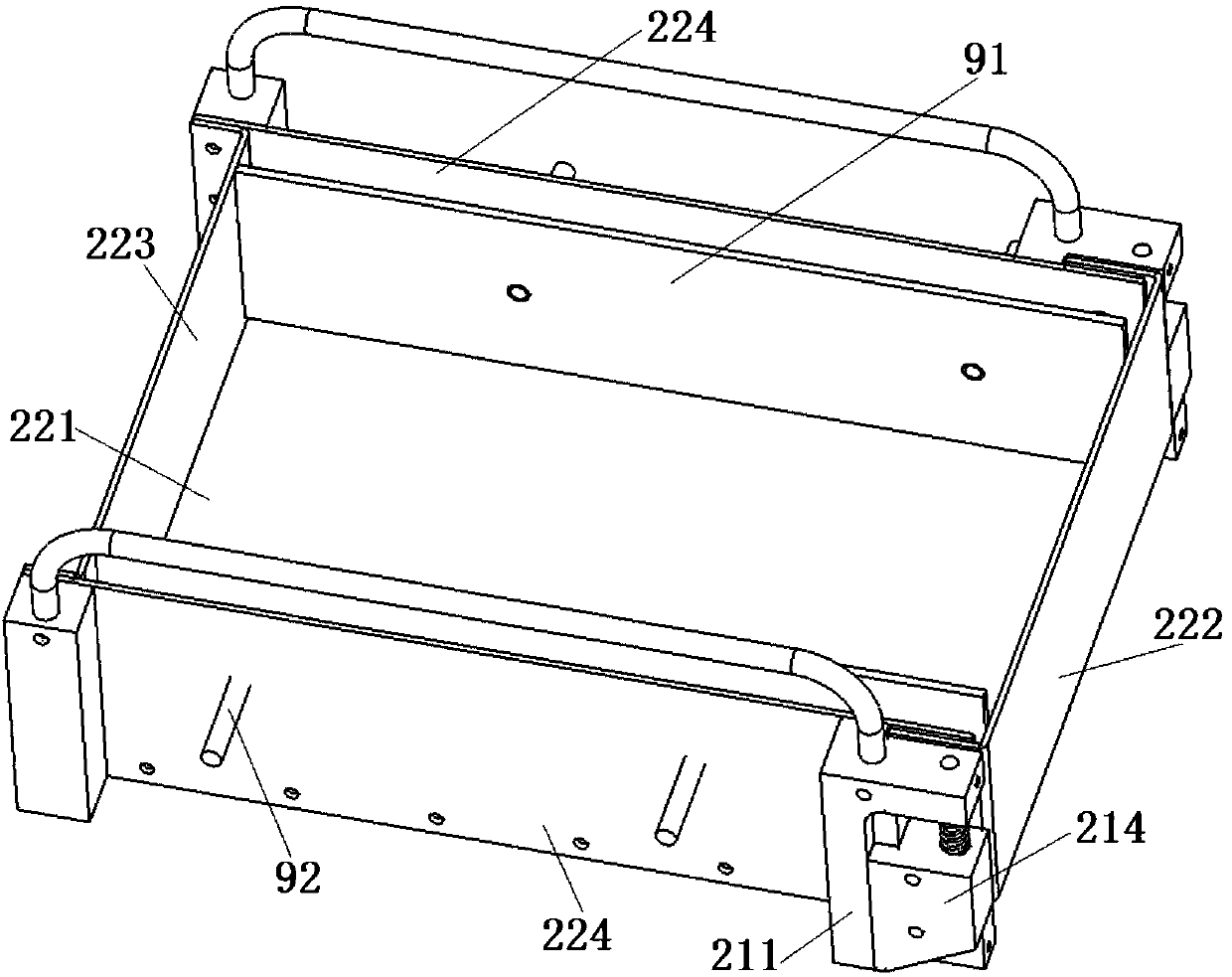

[0025] The feeding mechanism includes a storage box 20 , an opening assembly 21 and a shelf 30 . The material storage box 20 is a rectangular structure with an open top and a cavity inside. The material storage box 20 includes a material storage bottom plate 221 , a front box plate 222 , a rear box plate 223 and two side box plates 224 fixedly connected with the material storage bottom plate 221 . There are two opening assemblies 21, and the opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com