Bogie frame with built-in axle box for wide-gauge subway vehicles

A built-in, bogie technology, used in bogies, railway car body parts, transportation and packaging, etc., can solve the problem that the bogie cannot be arranged with current receivers, and achieve the effect of compact structure, increased lateral space, and complete functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

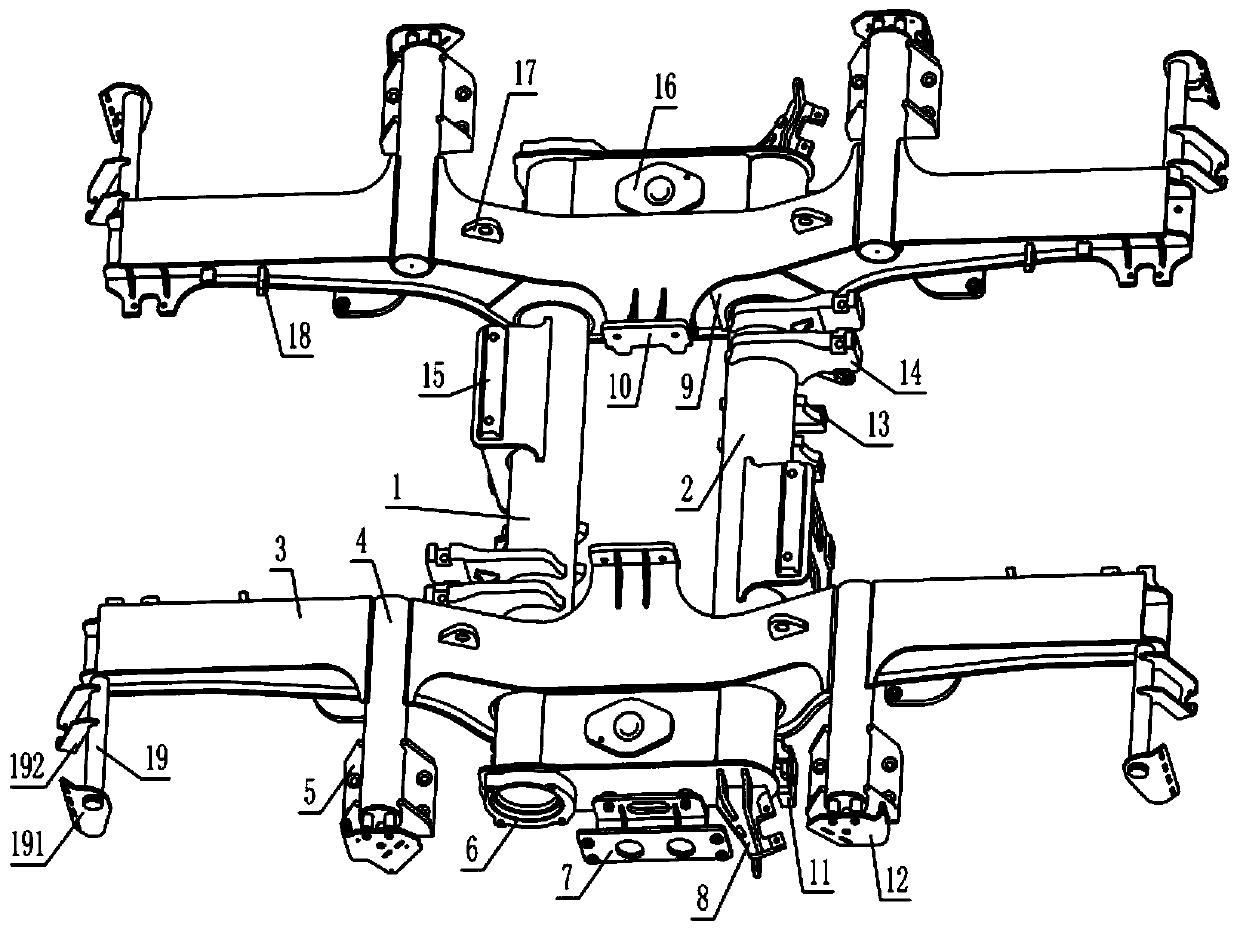

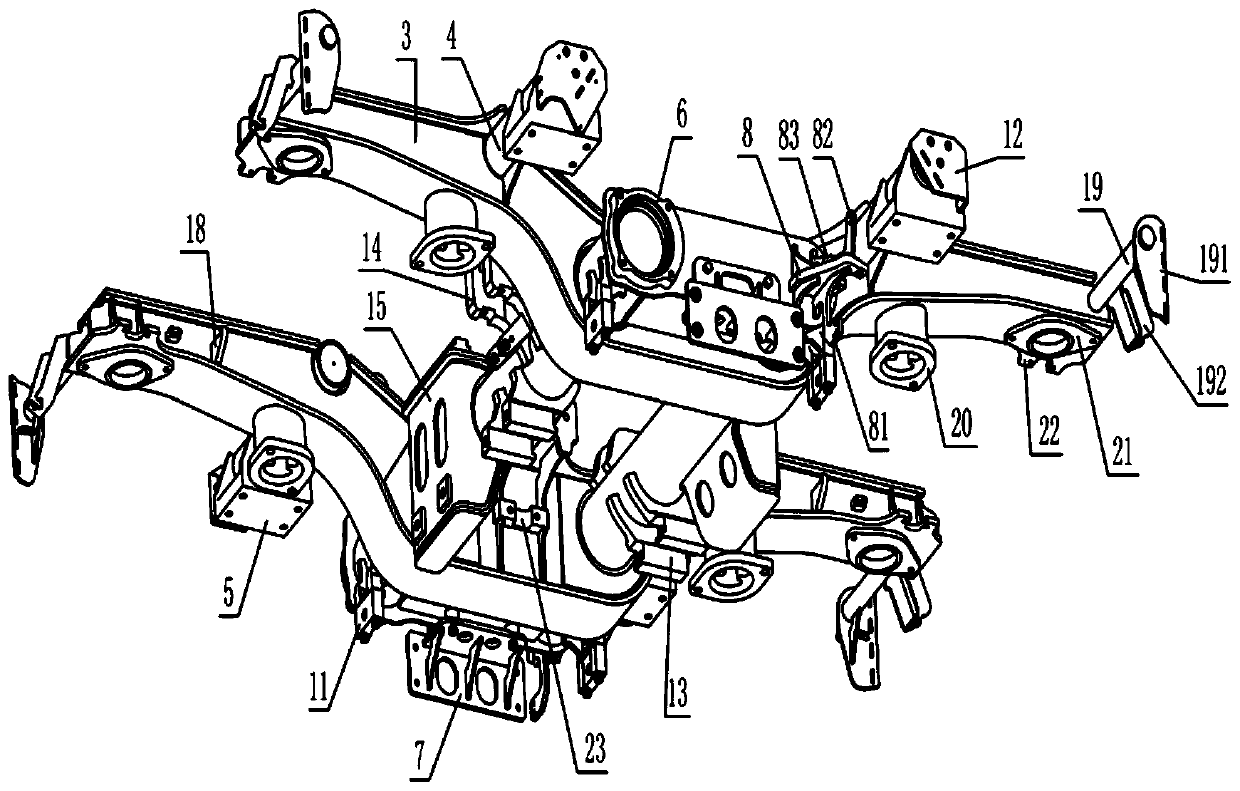

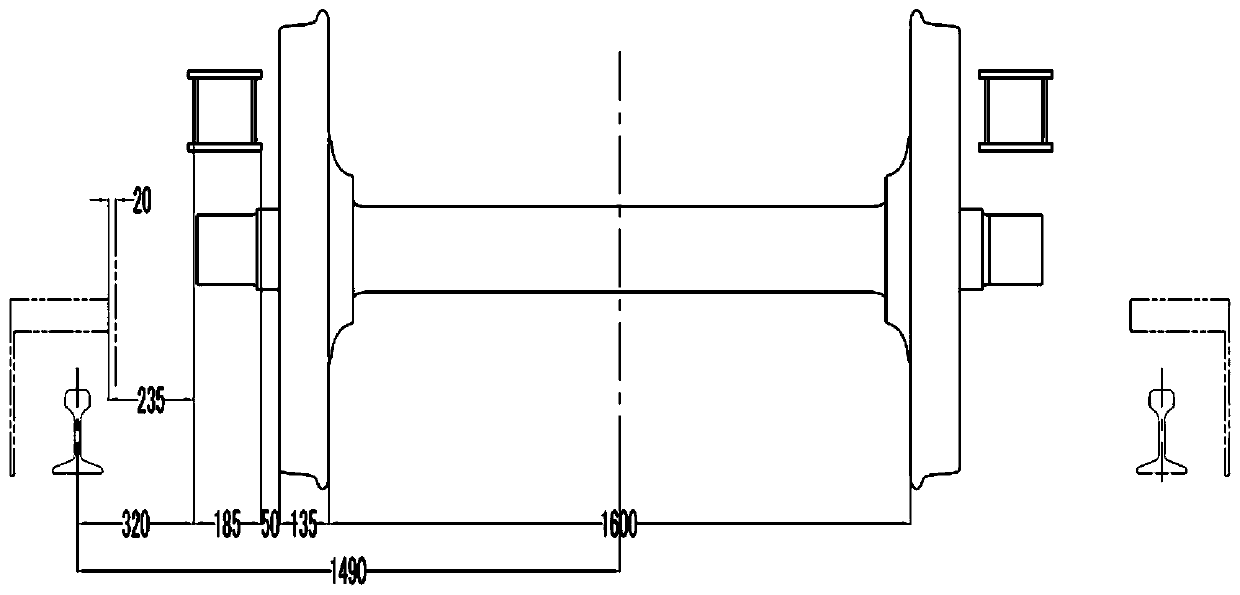

[0017] Example: see attached figure 1 and 2 A bogie frame with built-in axleboxes for wide-gauge subway vehicles provided by the present invention includes a front beam 1, a rear beam 2, a side beam 3, a brake pipe beam 4, a brake hanger 5, a torsion bar mount 6, Receiver mounting seat 7, secondary vertical shock absorber seat 8, connecting seat 9, lateral stop seat 10, cable mounting seat 11, shaft end adapter mounting seat 12, traction rod seat 13, gear box hanging seat 14 , Motor suspension seat 15, air spring seat 16, lifting lug 17, wheel set lifting seat 18, end mounting seat 19, rotating arm positioning rubber joint mounting seat 20, primary spring seat 21, primary vertical shock absorber seat 22. The second-series transverse shock absorber seat 23, etc., the main body of the frame is an H-shaped welded structure, symmetrically arranged, the front beam 1 and the rear beam 2 are seamless steel pipes, and are vertically connected to the two side beams 3 through the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com