Intelligent control method for hoisting of containers and container hoisting system

An intelligent control, container technology, applied in safety devices, transportation and packaging, load hanging components, etc., to reduce dependencies and uncertainties, avoid errors and inefficiencies, and reduce storage loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

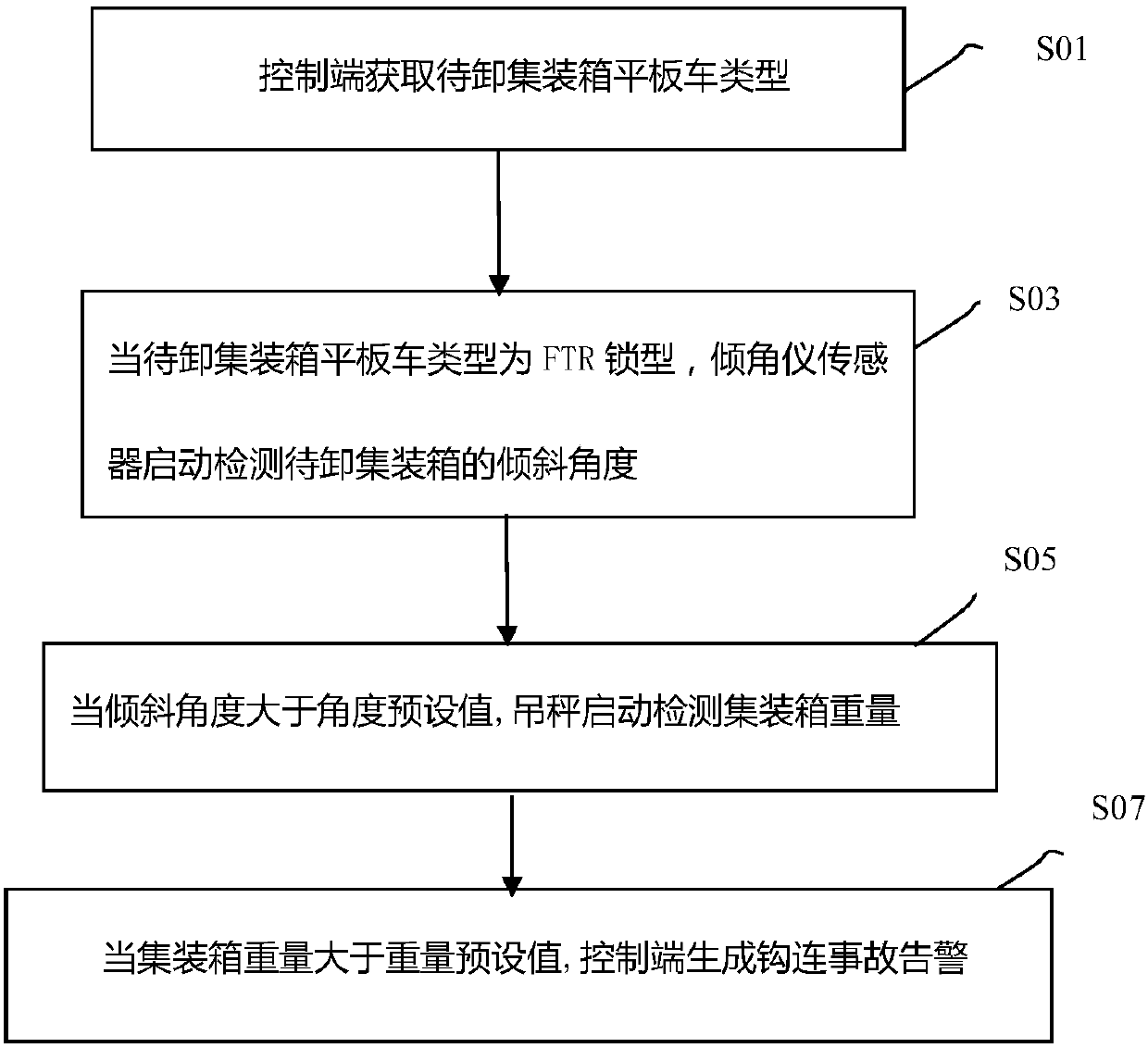

[0036] Such as figure 1 As shown, an intelligent control method for a container suspension box includes the following steps:

[0037] Step S01, the control terminal acquires the type of flatbed container to be unloaded;

[0038] Step S03, when the type of the container flatbed truck to be unloaded is the FTR lock type, the inclinometer sensor is activated to detect the inclination angle;

[0039] Step S05, when the inclination angle is greater than the angle preset value, the crane scale is started to detect the weight of the container;

[0040] Step S07, when the weight of the container is greater than the weight preset value, the control terminal generates a hooking accident alarm.

[0041] In the embodiment of the present invention, the control terminal refers to the driver's cab in the gondola system, and may also be a remote control center. Generally speaking, when the lock holes at the four corners of the container are not completely decoupled from the FTR lock, the c...

Embodiment 2

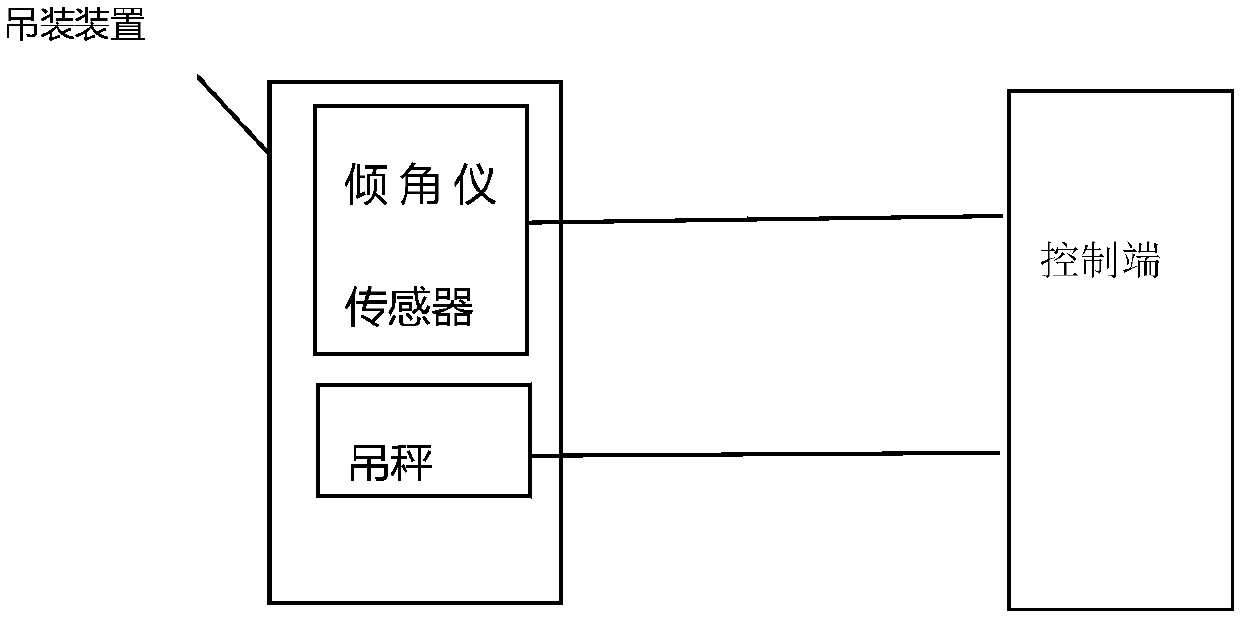

[0100] Such as figure 2 As shown, a container hanging box system includes a control terminal and a hoisting device. It is characterized in that an inclinometer sensor and a crane scale are provided on the hoisting device, and the inclinometer sensor and the crane scale are respectively connected to the control terminal, and the control terminal obtains the container to be unloaded. Flatbed truck type; when the flatbed truck type of the container to be unloaded is FTR lock type, the inclinometer sensor starts to detect the tilt angle; when the tilt angle is greater than the angle preset value, the crane scale starts to detect the container weight; when the container weight is greater than the weight preset value, the control terminal generates Hook accident warning.

[0101] Preferably, distance-measuring sensors are set at the lowest points of the four corners of the container, and the control terminal generates a jog-down signal for the hoisting device; the distance-measurin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com