Galvanized automatic barrel plating production line

A production line and barrel plating technology, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of increased production cost, unclean cleaning, waste of electroplating solution, etc., to achieve the effects of avoiding waste, saving raw material costs, and ensuring the quality of galvanizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

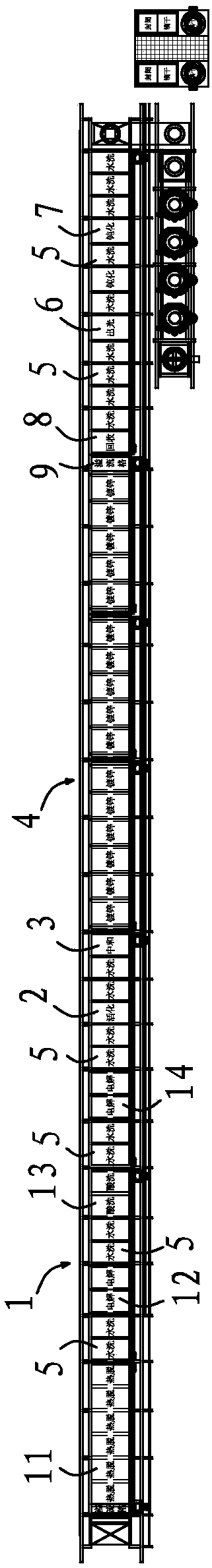

[0017] refer to figure 1 : Galvanized automatic barrel plating production line, including degreasing tank 1, acid activation tank 2, alkali neutralization tank 3 and galvanizing tank 4 arranged in sequence, degreasing tank 1 is multiple, acid activation tank 2 and alkali neutralization tank 3 There is a washing tank 5 between them, a degreasing tank 1, an acid activation tank 2, an alkali neutralization tank 3 and a galvanizing tank 4 below which are provided with outlet pipes, and one side of the galvanizing tank 4 is provided with an overflow grid tank 9. Wherein, the degreasing tank 1 includes a thermal degreasing tank 11 , a first electrolytic degreasing tank 12 , an acid degreasing tank 13 and a second electrolytic degreasing tank 14 arranged in sequence. One side of the galvanizing tank 4 is provided with an overflow grid groove 9, and the upper end su...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap