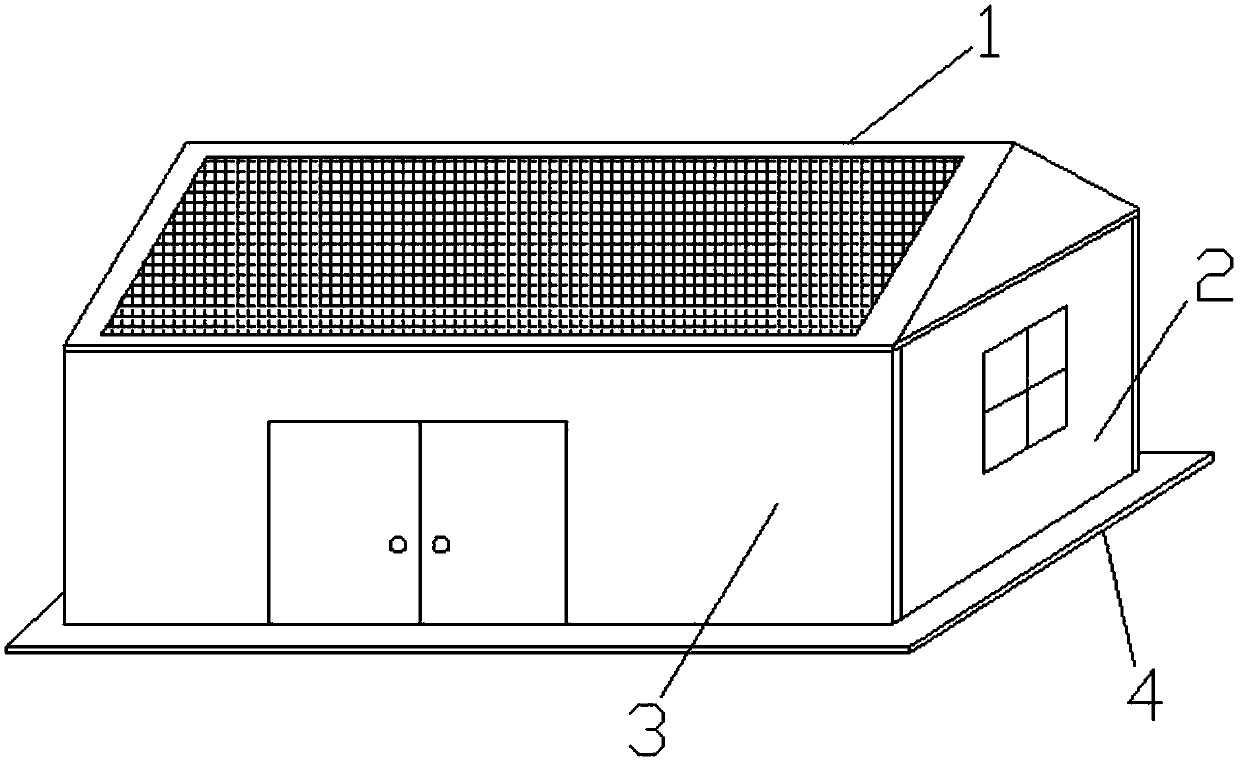

Wooden structure assembly type building house

A prefabricated, wood-structured technology, used in construction, building components, sustainable buildings, etc., can solve the problems of lack of energy-saving devices, inability to ensure the airtightness of houses, and inability to improve the practicability of wooden houses, achieving strong airtightness, enhanced Practicality, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

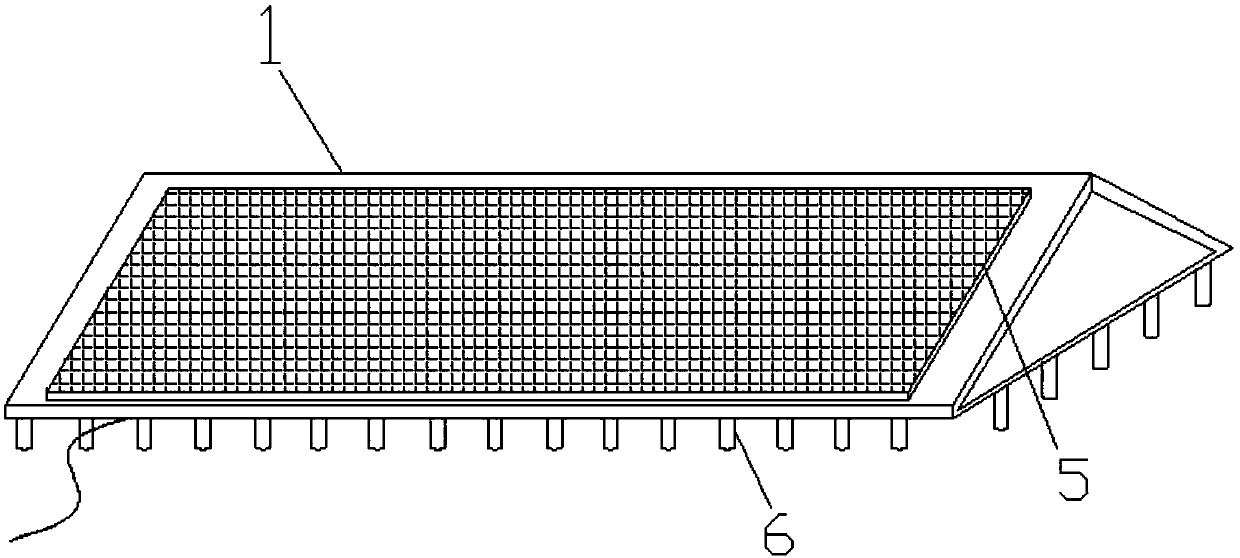

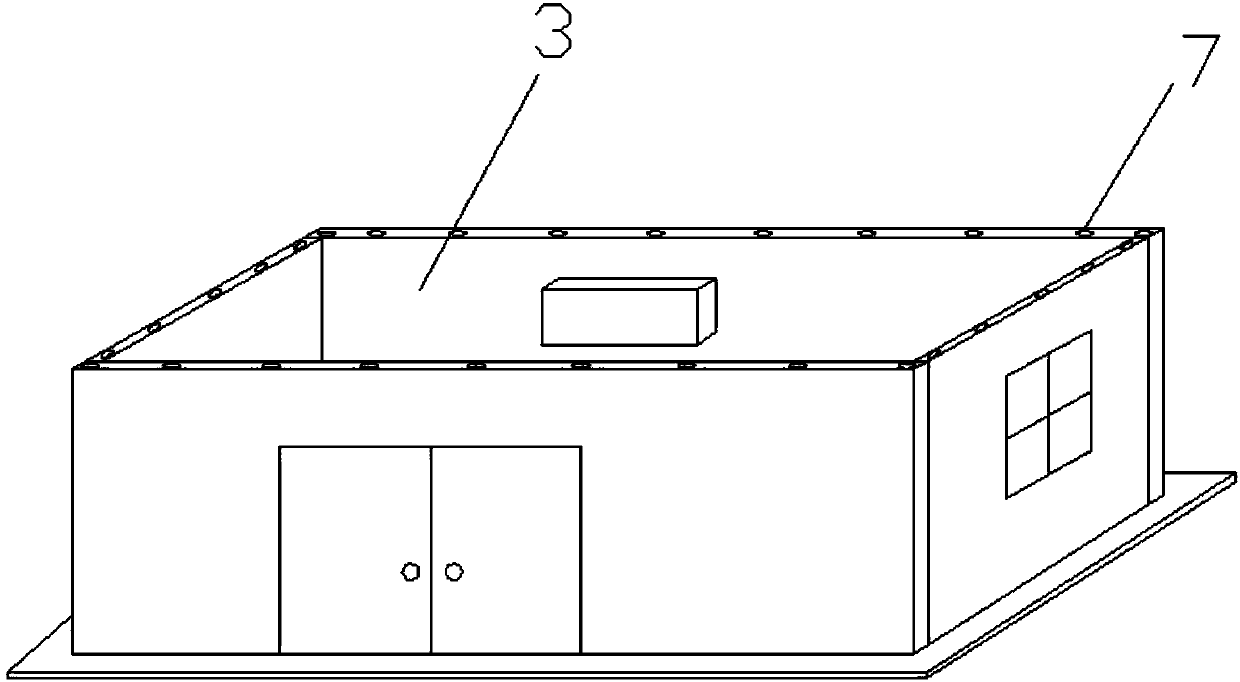

[0024] As a preferred embodiment of the present invention, the side plate embedding holes 9 are located at both ends of the surface of the horizontal plate 3 and the positions correspond to each other. Corresponding to the consistent side plate embedding holes, the effective alignment ensures the level of the side plate and the horizontal plate while ensuring the stability of the structural closure.

[0025] As a preferred embodiment of the present invention, the outer wall of the conversion box 8 is provided with a fixed steel sheet, and the fixed steel sheet is fixed on the surface of the horizontal plate 3 by screws. By fixing the conversion box, the stability and smoothness of the power transmission of the solar panel is ensured.

[0026] As a preferred embodiment of the present invention, the bottom plate 4 is fixed inside the ground through a fixing pile, and the fixing pile is fixedly connected with the ground below through a fixing device. The bottom plate fixed by pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com