Ground laying system

A ground and floor technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of long construction period and low laying efficiency, and achieve the effects of reducing labor costs, environmental protection, and keeping clean and tidy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

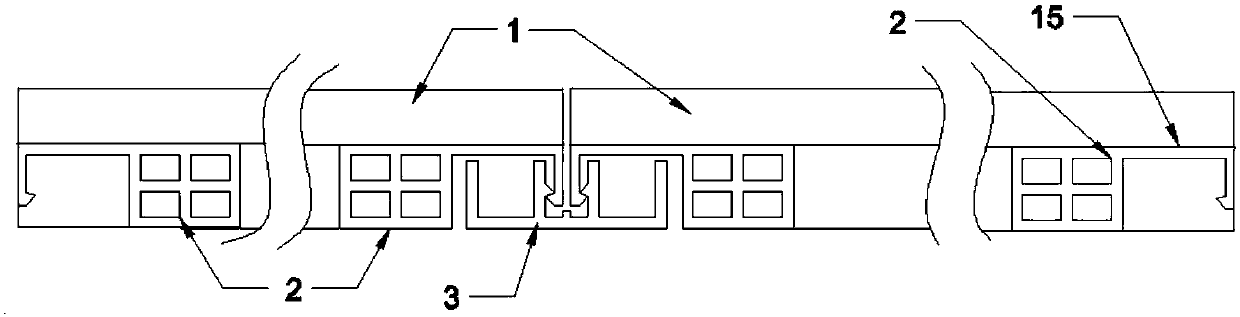

[0023] figure 1 A schematic structural view of a ground laying system according to an embodiment of the present invention is shown, as figure 1 As shown, the ground laying system of the embodiment of the present invention includes: fastener 3, fastener 2 and floor 1, fastener 3 is used to be fixedly connected with the ground, fastener 2 is installed on the floor 1, fastener 2 and fastener 3 Snaps in to secure the floor to the ground.

[0024] The floor in the embodiment of the present invention can be a common standard board, such as a 300mm*300mm solid composite board, a 300mm*600mm solid composite board, a 600mm*600mm solid composite board, etc.; it can also be a parquet standard board, such as a solid waveguide board (its width*length=150*600mm), solid triangular plate (the size of its three sides is 600*600*849mm), solid corner plate, etc. The parquet standard board is used in conjunction with the general standard board to meet the normative solidification supplementary ...

Embodiment 2

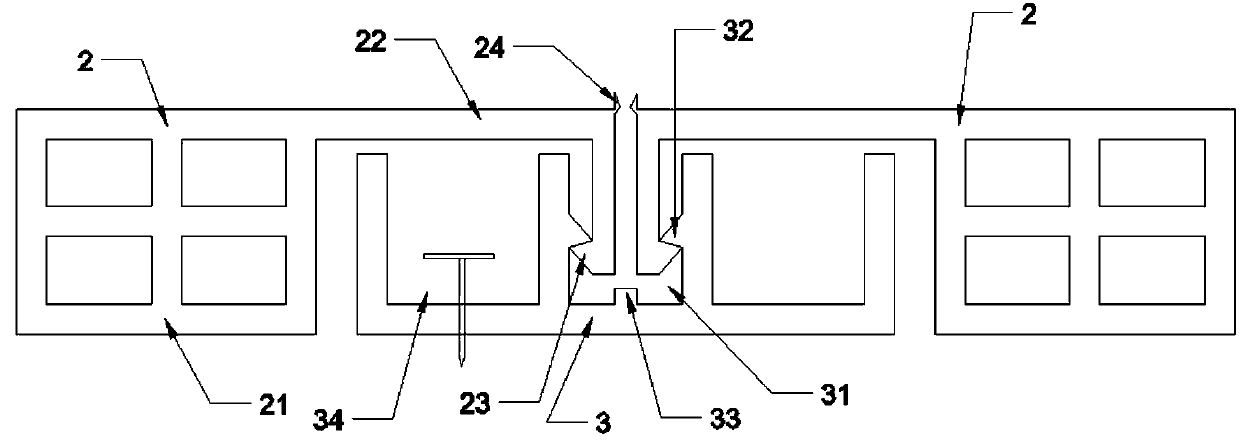

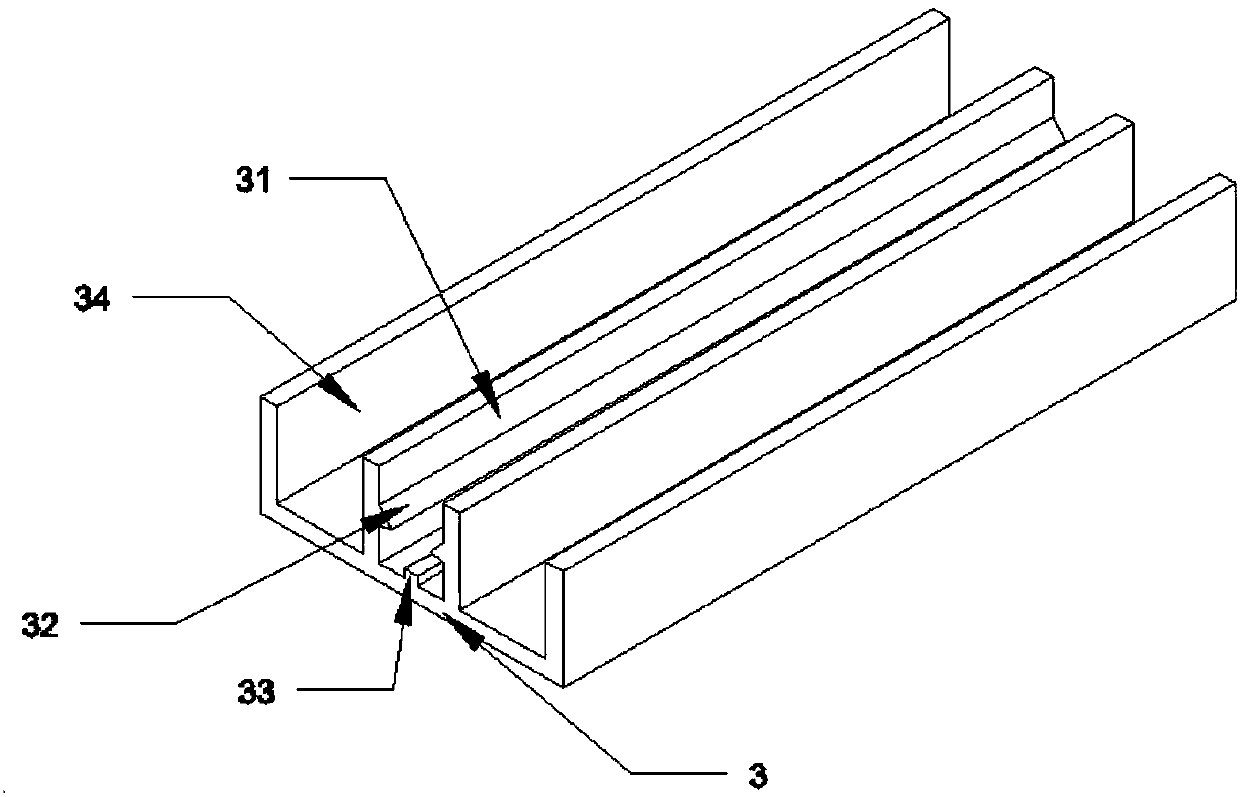

[0030] On the basis of the first embodiment above, optionally, as figure 2 and image 3 As shown, the fastener 3 includes a fastener body, and the fastener body has a slot 31 , and the opening of the slot 31 faces away from the ground. The two inner groove walls of the slot 31 are provided with first protrusions 32, and the clip 2 is inserted into the slot 31, and is clamped between the two first protrusions 32, so that the clip 2 is better connected with the buckle. Part 2 is clipped to ensure that the floor 1 is firmly installed on the ground. The first protrusion 32 can also prevent the second protrusion 23 of the clip 2 from contacting the groove wall of the fastener 2 during the sliding down process, so as to avoid unnecessary wear of the second protrusion 23 .

[0031] In a preferred embodiment of the present invention, as figure 2 and Figure 4 As shown, the clip 2 includes a clip body 21 and a hook, and the clip body 21 is connected to the bottom of the floor 1 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com