Rope wheel type glass lifting device

A technology of glass lifting and rope pulley, which is applied in door/window accessories, buildings, and wing fan control mechanisms, etc. It can solve the problems of small traction, high cost, glass lifting failure, etc., and achieves high integration, simple structure, Easy to assemble effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

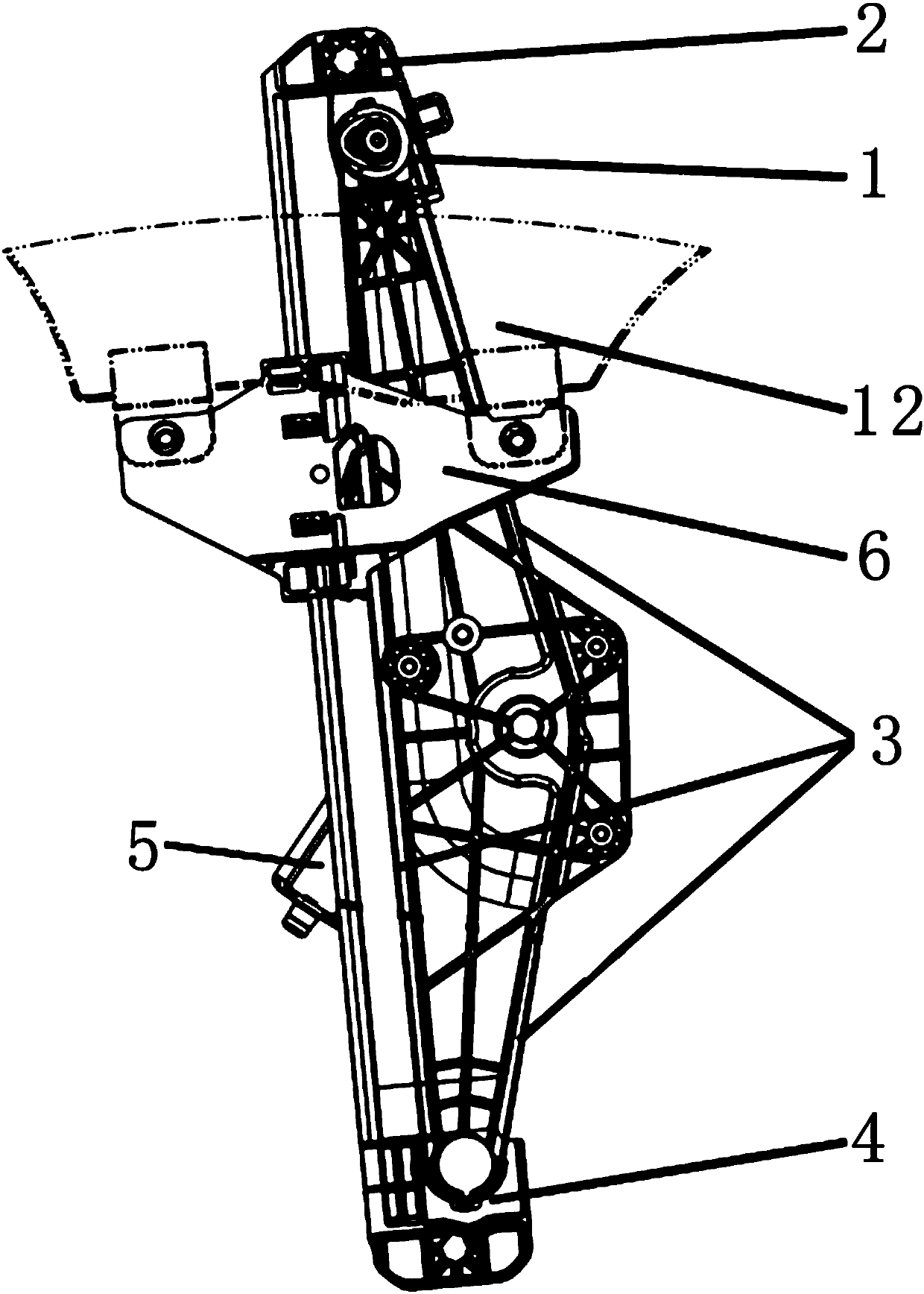

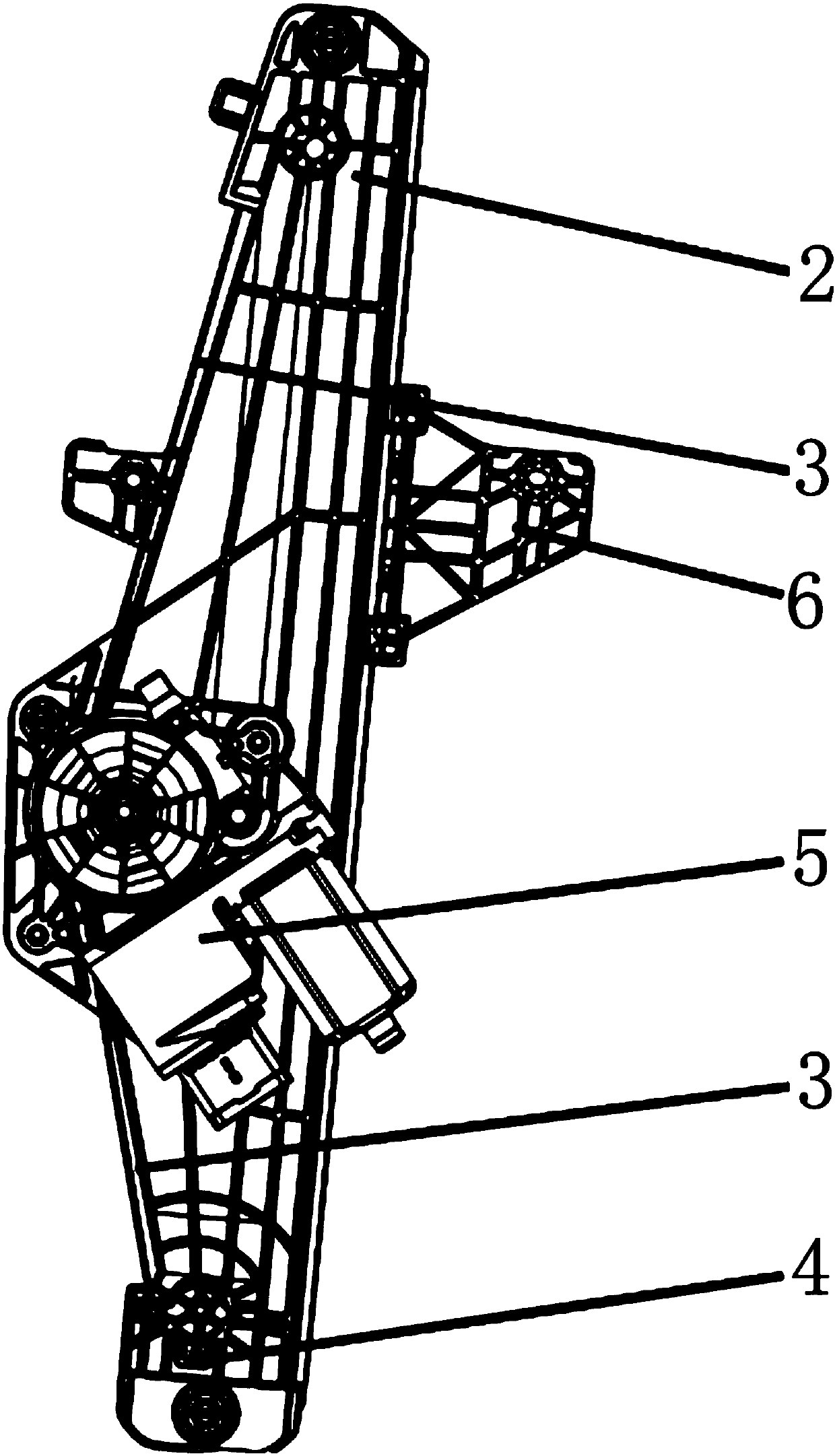

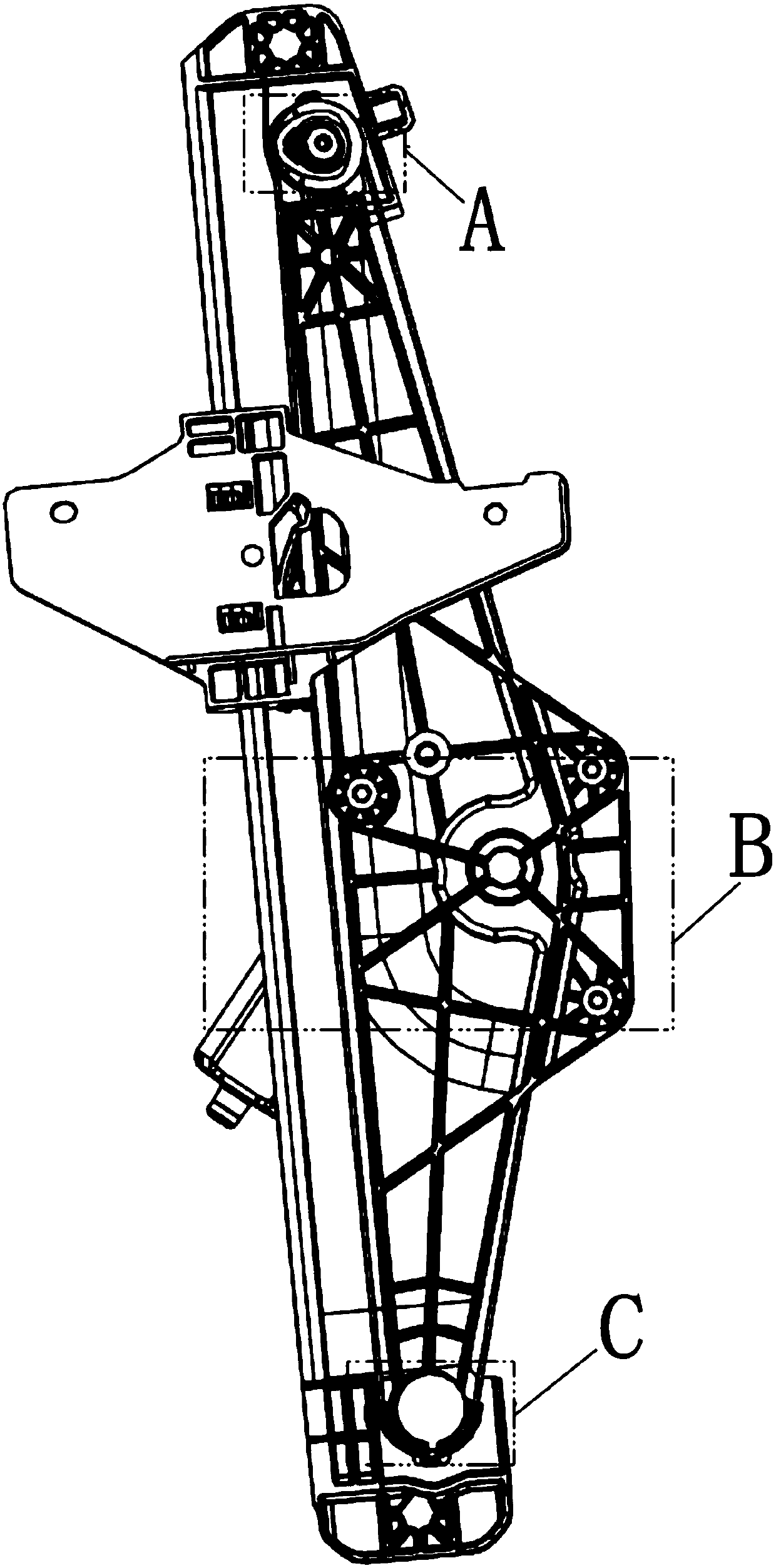

[0039] like Figure 1 to Figure 13 As shown, a rope-wheel type glass lifter includes a plastic guide rail 2, a traction wire 3, a guide block 4 and a drive motor 5, and a guide wheel 1 is installed on the top of the plastic guide rail 2 (the guide wheel 1 reaches the upper position of the plastic guide rail 2 to determine The role of the pulley), the bottom of the plastic guide rail 2 is equipped with a cylindrical support boss 23, and the outside of the cylindrical support boss 23 is fixed with two square grooves 24. The matching clamping groove on the outer wall of the boss 23, the outer wall of the guide block 4 has a traction steel wire guide groove 431, and the inner two ends of the guide block 4 are provided with an undercut 44 that is engaged with the square groove 24. During use, the guide block 4 is clamped and mounted on the outside of the cylindrical support boss 23 of the plastic guide rail 2, so as to realize the purpose of fixing the guide block 4 on the bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com