Frequency measuring method of vibrating wire type sensor

A vibrating wire sensor, frequency measurement technology, applied in the measurement of resonance frequency, measurement device, measurement of ultrasonic / sound wave / infrasonic wave, etc., can solve the problems that cannot meet the requirements of reliability, accuracy and speed, so as to ensure reliability, The effect of expanding the sweep range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

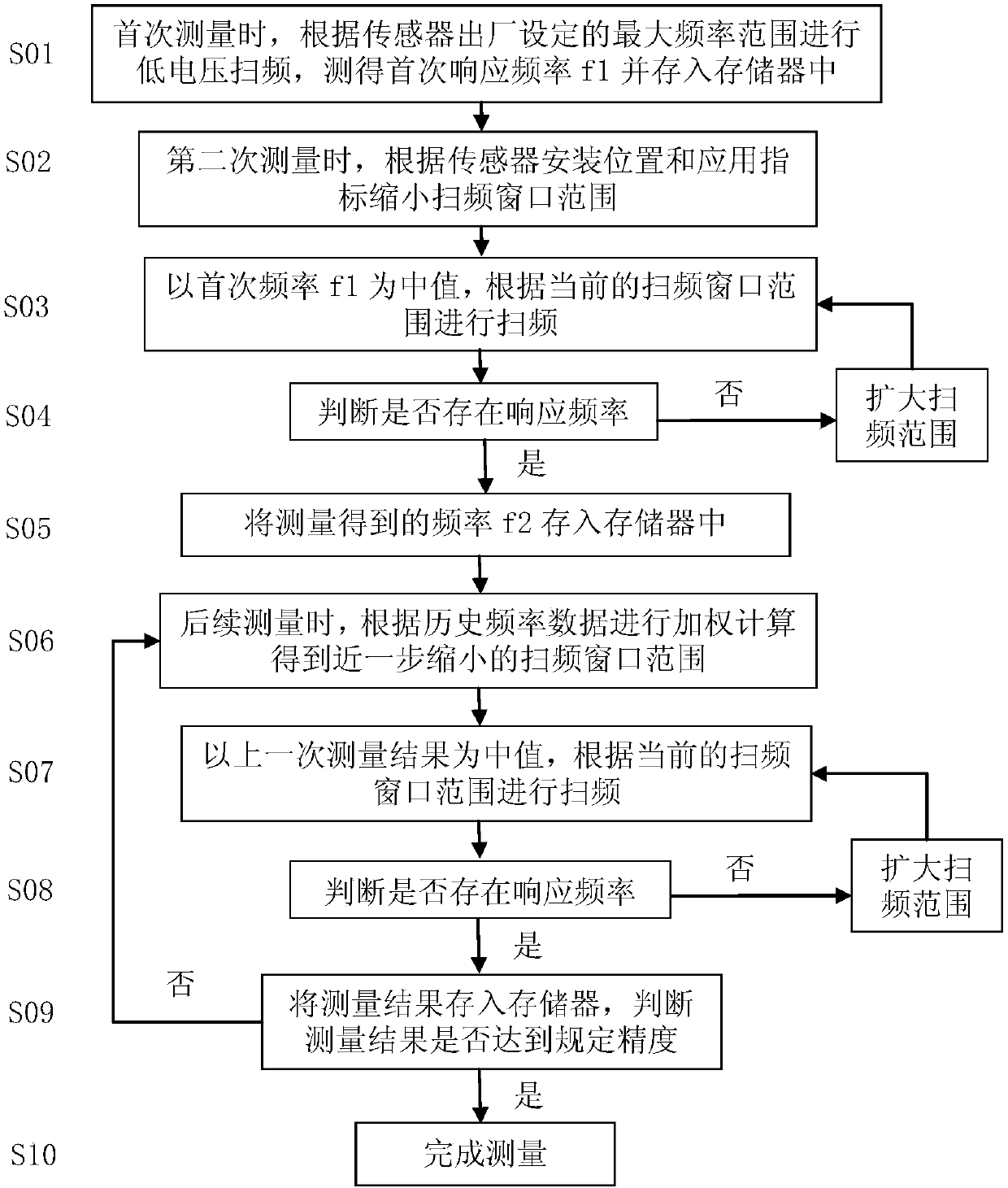

[0027] Such as figure 1 As shown, the present invention is a frequency measurement method of a vibrating wire sensor, comprising the following steps:

[0028] S01, when measuring for the first time, perform a low-voltage frequency sweep according to the maximum frequency range set by the sensor at the factory, measure the first response frequency f1 and store it in the memory.

[0029] S02, during the second measurement, narrow the frequency sweep window range according to the sensor installation location and application indicators.

[0030] S03, taking the first frequency f1 as the median value, and performing frequency scanning according to the current frequency scanning window range.

[0031] S04, judge whether there is a response frequency, if yes, execute step 5, otherwise, expand the range of the frequency sweep window and return to S03.

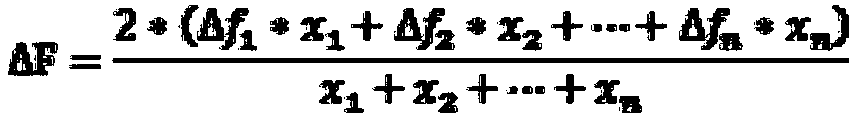

[0032] S05, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com