A chemical process simulator for intelligent manufacturing

A chemical process, intelligent manufacturing technology, applied in the direction of instruments, simulators, general control systems, etc., can solve problems such as limiting the expansion of system functions, increasing workload, etc., to achieve high versatility, high scalability, high versatility and Expansion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be noted that the following embodiments are intended to facilitate the understanding of the present invention, but do not limit it in any way.

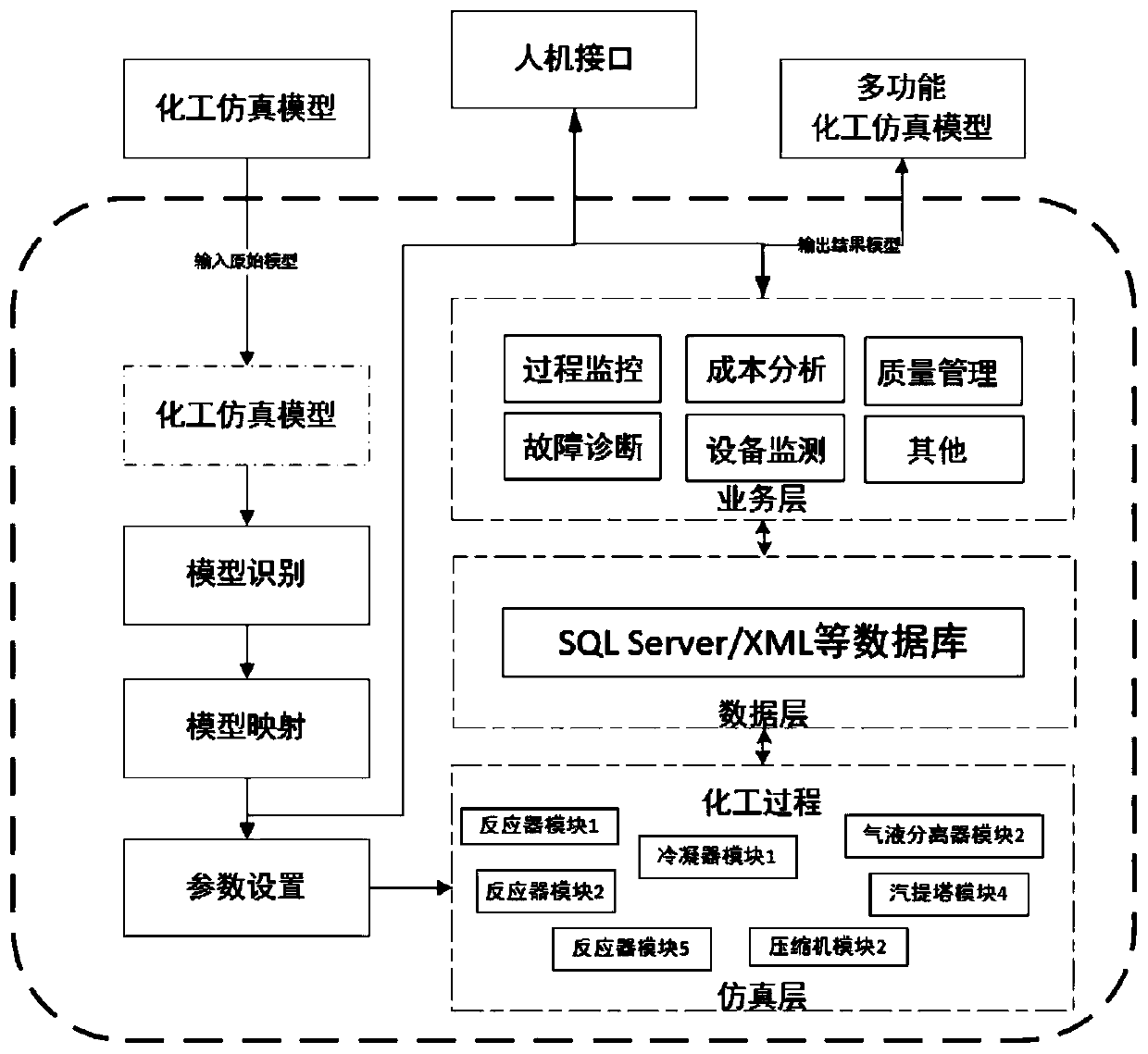

[0091] The functional structure of the chemical process simulator for intelligent manufacturing is as follows: figure 1 shown, including:

[0092] Man-machine interface module: design user-friendly interface GUI, use menu design, avoid tedious programming call to realize parameter setting;

[0093] Business function module: call the corresponding data in the database, expand the MES layer of the chemical simulation process, and realize the business simulation analysis of different functions. The business layer can span different management and control levels. The main functions are listed in the figure;

[0094] Database: collect the data of each underlying module, send response control instruc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com