Material out-put and in-put management system, in-put management method and out-put management method

A management system, in-out technology, applied in the field of material in-out management system, can solve problems such as error-prone and low efficiency, and achieve the effect of improving accuracy, avoiding human error, and improving data collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

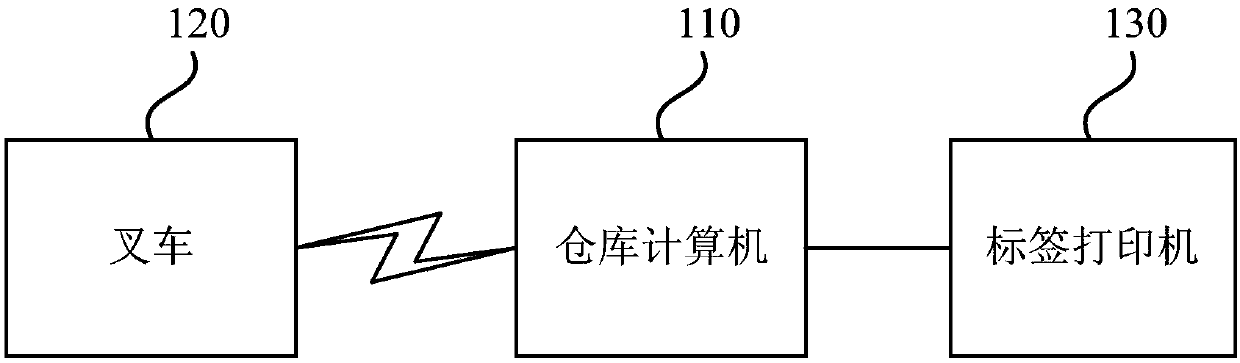

[0025] figure 1 It is a schematic structural diagram of a material storage and output management system provided by Embodiment 1 of the present invention. This embodiment is applicable to the situation of managing the data of material storage and output, such as figure 1 As shown, the material in-out warehouse management system described in this embodiment includes: a warehouse computer 110 , a forklift 120 and a label printer 130 .

[0026] Among them, the warehouse computer 110 is used to receive the material storage data or the material output data, and send the storage instruction or the output instruction to the forklift 120, receive the review data of the pallet material by the forklift 120, and check the data according to the review data when entering the warehouse. Generate a material storage label and send a printing command to the label printer, save the material storage data and the corresponding review data of each pallet material, or the material storage data and ...

Embodiment 2

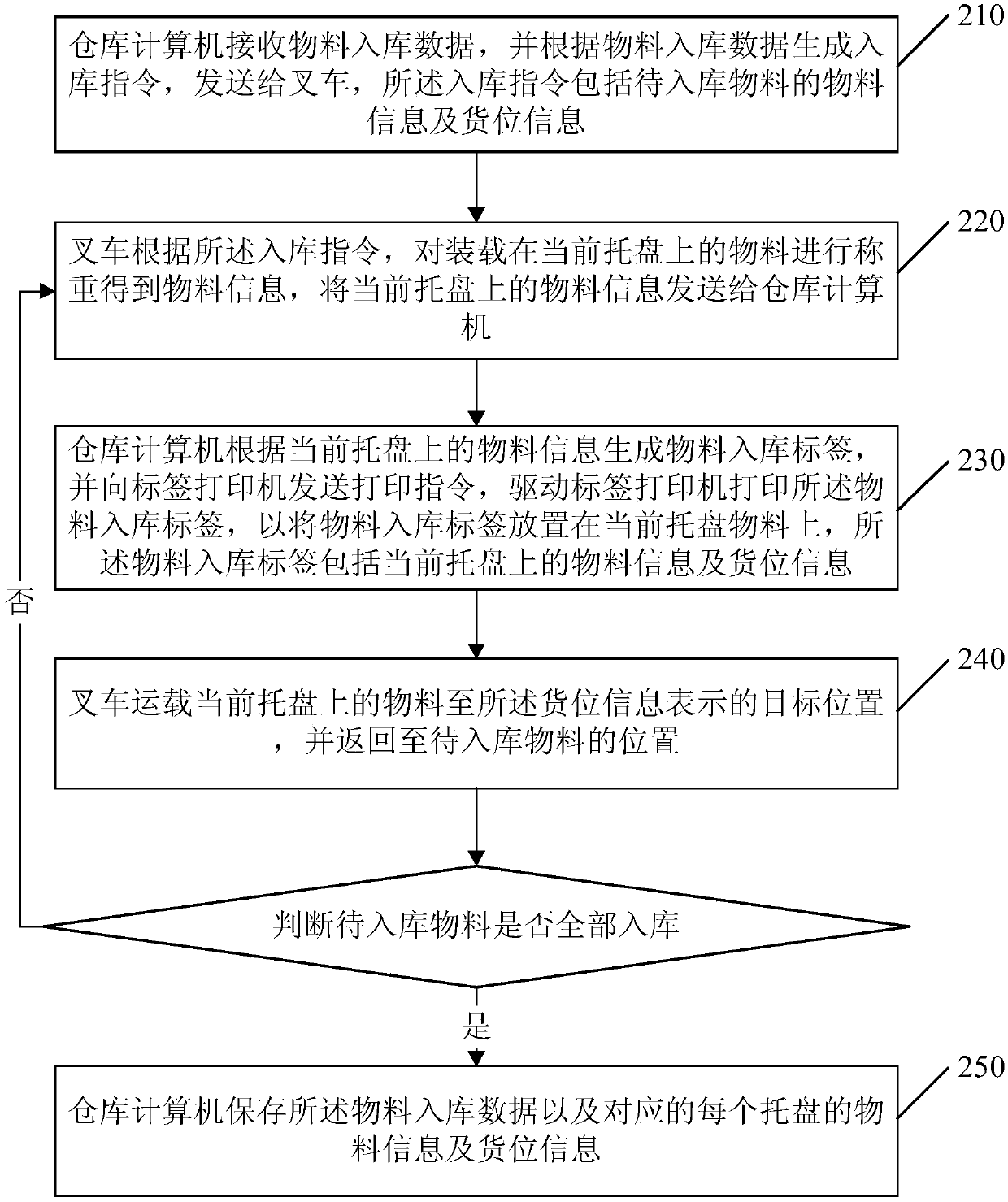

[0047] figure 2 It is a flowchart of a material storage management method provided by Embodiment 2 of the present invention. This embodiment is applicable to the situation of managing the data of material storage. This method can be implemented by the material storage management system provided by the above embodiment To perform, the method specifically includes the following steps:

[0048] Step 210, the warehouse computer receives the material storage data, generates a storage instruction according to the material storage data, and sends it to the forklift. The storage instruction includes material information and location information of the materials to be stored.

[0049] Among them, the material storage data can be sent to the warehouse computer by the truck scale, or can be sent to the warehouse computer by other equipment such as balers. Materials to be put into storage include raw materials, finished products, auxiliary supplies or semi-finished products, etc.

[00...

Embodiment 3

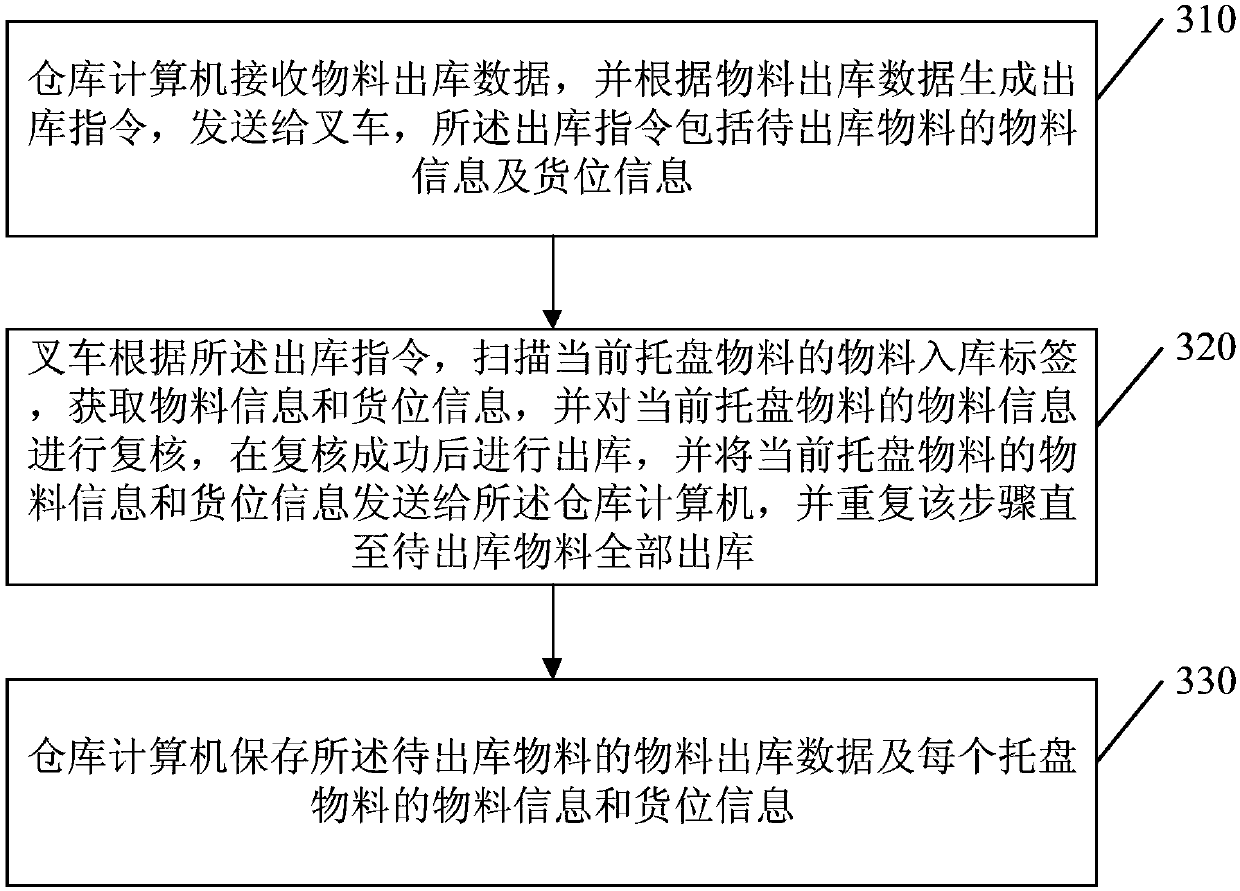

[0072] image 3 It is a flow chart of a material outbound management method provided by Embodiment 3 of the present invention. This embodiment is applicable to the situation of managing material outbound data. This method can be implemented by the material inbound and outbound management system provided in the above embodiment To perform, the method specifically includes the following steps:

[0073] In step 310, the warehouse computer receives the material outbound data, generates an outbound instruction according to the material outbound data, and sends it to the forklift. The outbound order includes material information and location information of the material to be outbound.

[0074] Among them, the materials to be delivered include raw materials, finished products, auxiliary supplies or semi-finished products, etc. The material output data can be sent to the warehouse computer by the production server, or sent to the warehouse computer by the ERP system. When the material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com