Reverse flange structure of reactor pressure vessel with integrated steam channel

A reverse flange and pressure vessel technology, applied in reactors, sealing, reducing greenhouse gases, etc., can solve problems such as inability to adapt to high controllability, and achieve the effect of relatively thick wall, reasonable structure, and reduced manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

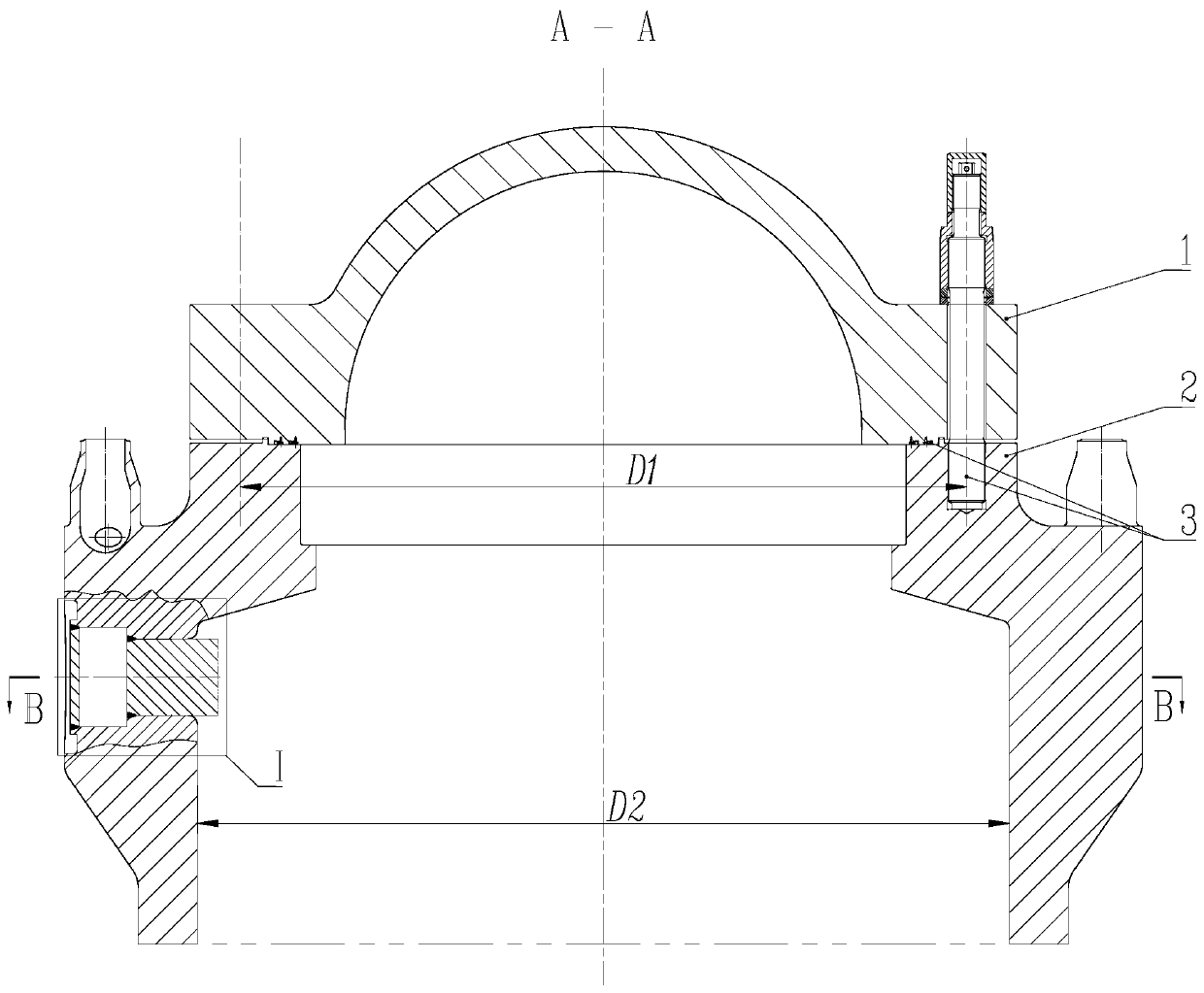

[0031] Such as Figure 1 to Figure 5 As shown, the reverse flange structure of the reactor pressure vessel with integrated steam channels is used for the connection between the barrel of the reactor pressure vessel and the top cover 1, and the reverse flange structure includes the reverse method Flange body 2, the reverse flange body 2 has a cylindrical structure with an inner diameter larger than the other end, and the end of the reverse flange body 2 with a smaller inner diameter is also provided with a plurality of bolt holes, the plurality of The bolt holes are evenly distributed on a ring, and the diameter of the ring is smaller than the inner diameter of the larger end of the opposite flange body 2 .

[0032] Specifically, this reverse flange is used as a connecting piece between the cylinder body of the reactor pressure vessel and the top cover 1, that is, when the reverse flange body 2 is in use, one end with a threaded hole is provided for connecting with the top cover ...

Embodiment 2

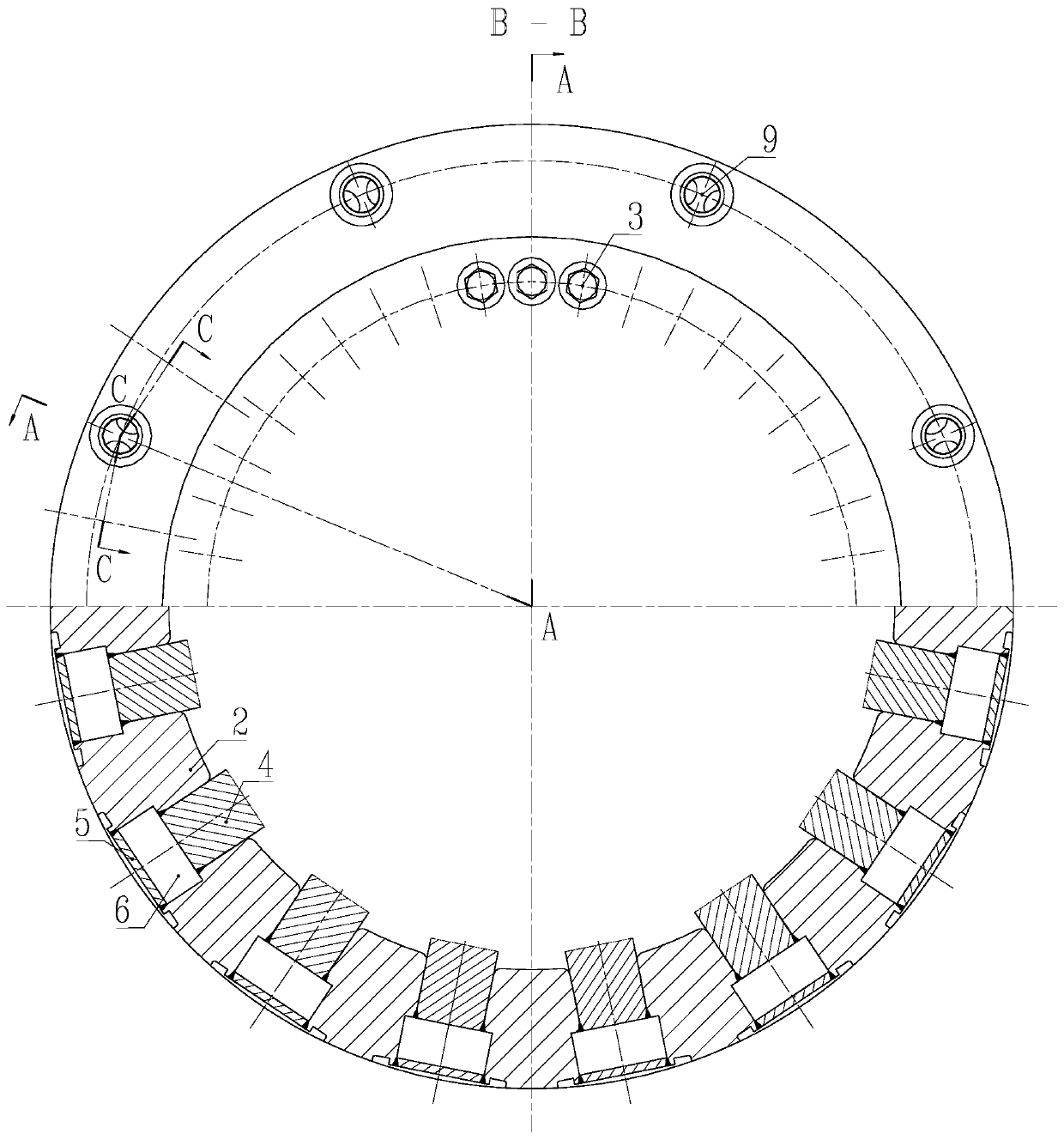

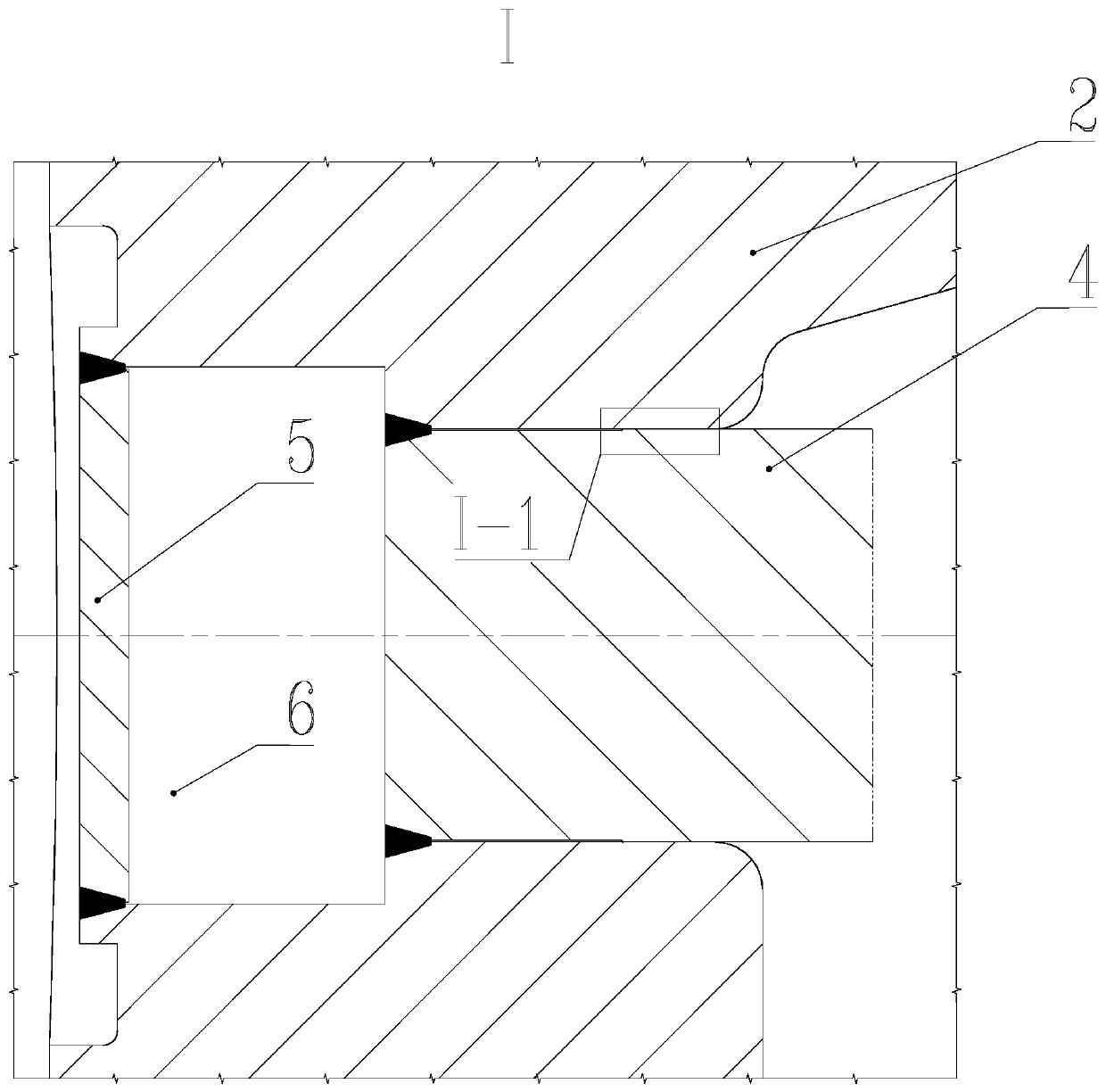

[0034] The present embodiment is further limited on the basis of embodiment 1, as Figure 1 to Figure 5 As shown, the reverse flange body 2 is also provided with a plurality of steam cavity holes 6, and each steam cavity hole 6 runs through the inside and outside of the side wall of the reverse flange body 2, and also includes the same number of steam cavity holes 6 There are equal number of end caps 5, and one end cap 5 is fixed on the end of each steam chamber hole 6 away from the center of the reverse flange body 2, and the end cap 5 is used as a sealing plate corresponding to the outer side of the steam chamber hole 6;

[0035] Each steam chamber hole 6 is provided with a steam generator 4 inside;

[0036] It also includes a steam hole 8 and a steam outlet connection 9 arranged on the reverse flange body 2 , and the steam hole 8 serves as an intermediate communication channel between the steam chamber hole 6 and the steam outlet connection 9 .

[0037] The above scheme pr...

Embodiment 3

[0047] This embodiment is further limited on the basis of any one of the technical solutions provided by any one of the above embodiments: in order to facilitate the connection between the reverse flange and the cylinder, the end of the reverse flange body 2 with a larger diameter is also set There are welding grooves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com