Liquid cooling plate for soft package power battery and battery module

A power battery and battery module technology, applied in the battery field, can solve the problems of unsatisfactory heating effect, energy loss, weak heat dissipation capacity, etc., and achieve the effects of improving use safety, simple structure and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

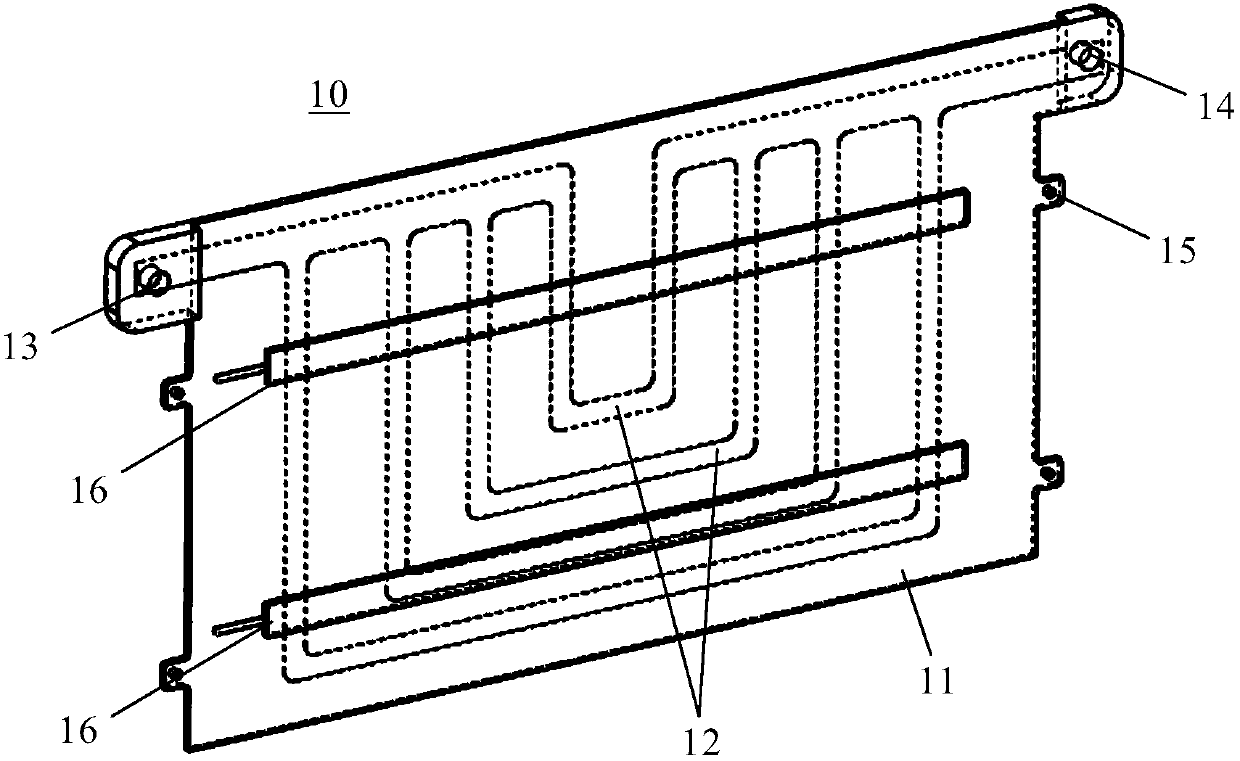

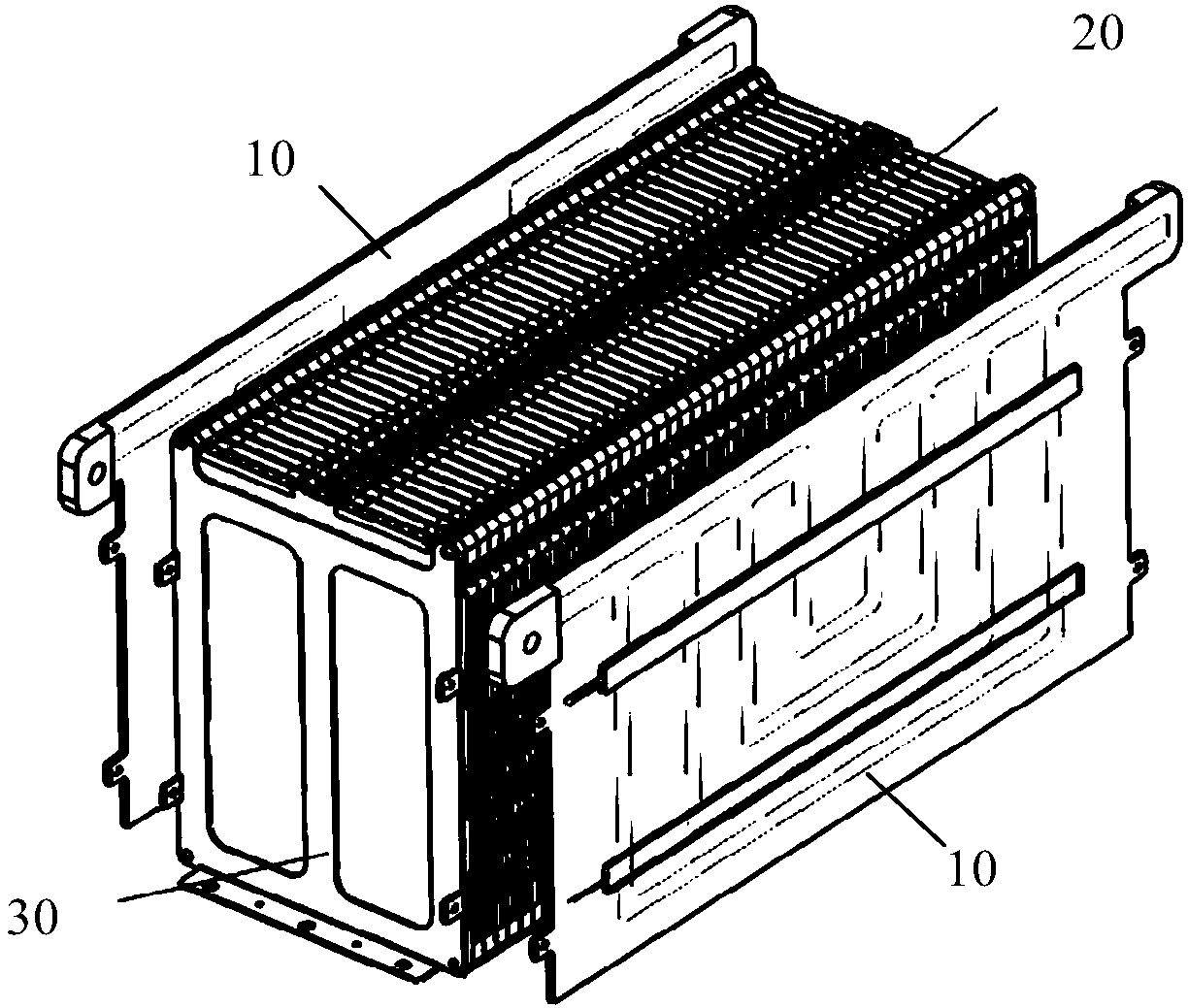

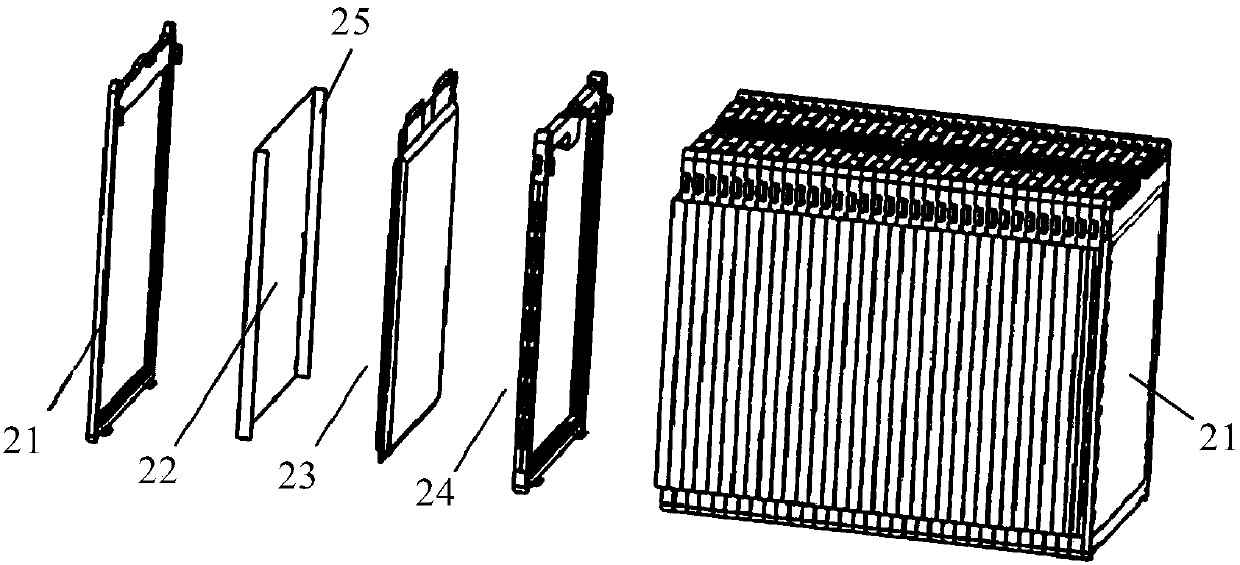

[0021] like figure 1 As shown, the liquid cooling plate 10 for flexible packaging power batteries of the present invention includes a rectangular plate body 11 and a PTC (thermistor) electric heating strip 16, wherein: the inside of the plate body 11 is provided with several flow channels 12, and the two ends of the plate body 11 are respectively A water inlet 13 and a water outlet 14 are provided, and each flow channel 12 is connected with the water inlet 13 and the water outlet 14, and the water inlet 13 and the water outlet 14 are respectively connected with an external water supply device and a water storage device (not shown in the figure) Connected; the side wall of the plate body 11, that is, when the battery module is assembled, the side wall of the plate body 11 facing the outside is fixed with at least one PTC electric heating strip 16 by pasting or welding, and the PTC electric heating strip 16 is connected to the external power supply device (Fig. not shown in ), t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com