Manufacturing method of metal high temperature gas assisted moulded and combined plastic

A technology of gas-assisted forming and manufacturing method, applied in the direction of coating, etc., can solve the problems of high manufacturing cost, increased machining accuracy tolerance, labor-intensive and time-consuming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

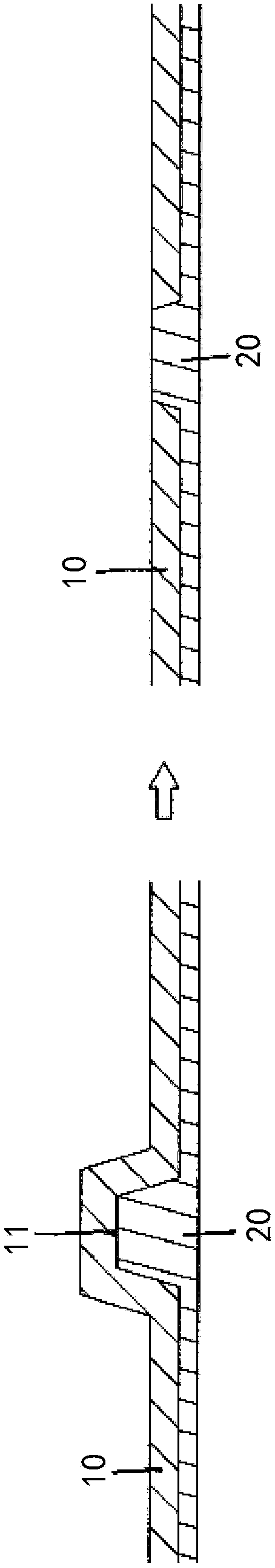

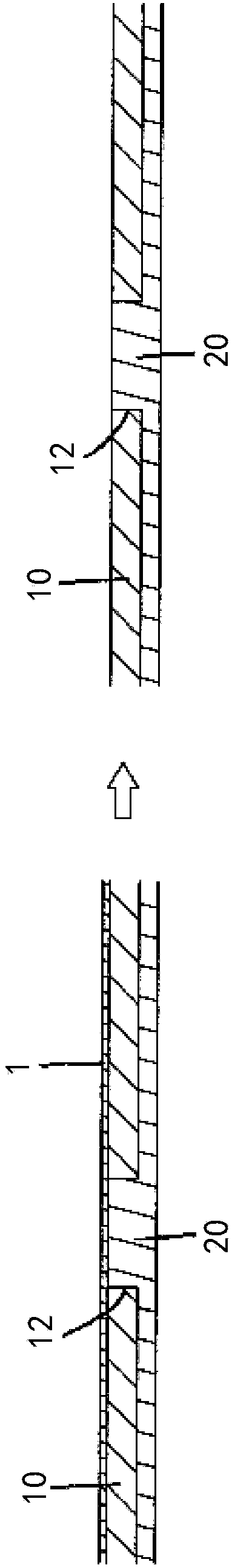

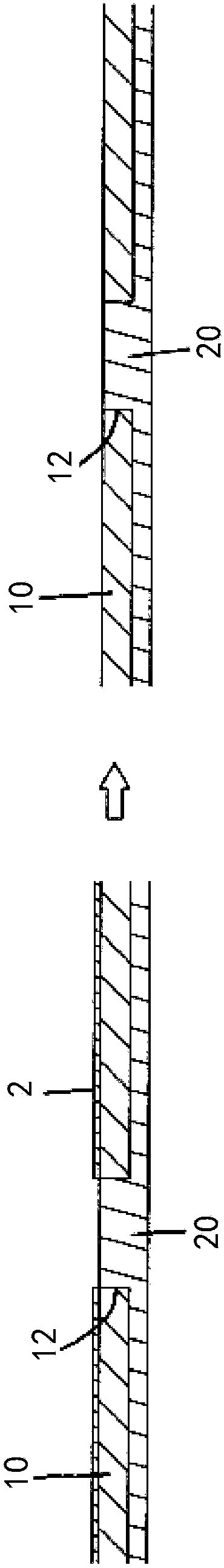

[0035] In order to make it easy for those skilled in the art to deeply understand the structure of the present invention and the functional benefits that can be achieved, specific embodiments are listed hereby, and detailed descriptions are as follows in conjunction with the drawings:

[0036] A manufacturing method of high-temperature gas-assisted forming metal components, which is to place a metal plate in a mold, and apply pressure to the metal plate, use a heating device to heat the mold to soften and deform the metal plate, and then input high pressure The gas blows the softened metal sheet into the mold cavity, takes it out after forming, and obtains a high-temperature gas-assisted forming metal component. Wherein, the pressure and temperature applied on the metal sheet are determined according to the material and thickness of the metal sheet, and the input high-pressure gas and the pressure range applied to the metal sheet can both be 50kg / cm 2 ~350kg / cm2 The temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com